Method for managing volatile organic waste gas

A volatile organic and volatile technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve the problems of microorganisms not easy to hang film, low processing efficiency, large resistance, etc., and achieve good load fixing effect and smooth operation Low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

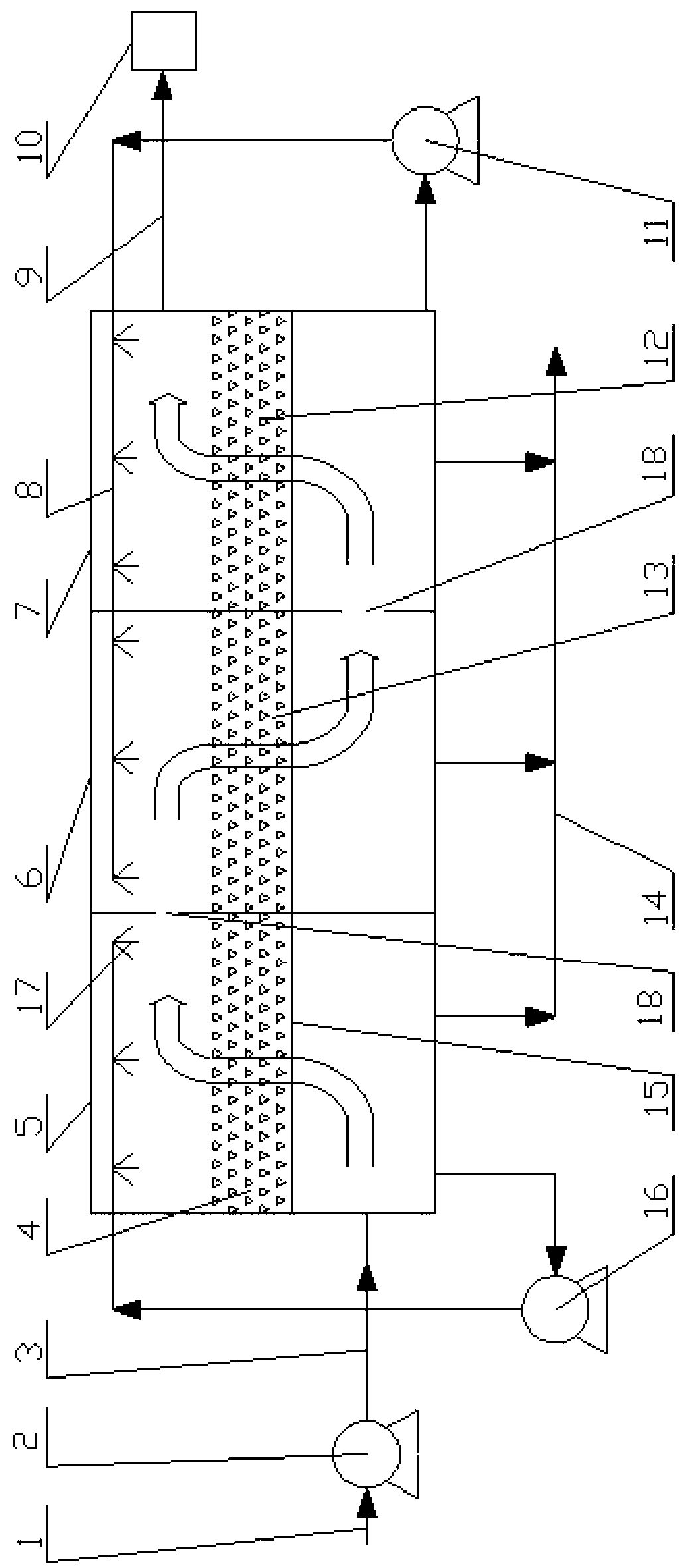

Method used

Image

Examples

Embodiment 1

[0024] Filtration device filling production:

[0025] 1. Take the activated sludge produced by the biochemical treatment of sewage in petroleum refineries, that is, the activated sludge in the sludge concentration tank. The activated sludge: starch: urea: potassium dihydrogen phosphate: toluene and xylene is 1000: 100: 5~ 15; 1~5:1~5 (mass ratio) mixing, 1m 3 Add 10 kg of sludge with a moisture content of 90% to 92% to the ceramsite and place it for 3 days. The porous ceramsite can be purchased from Jiangxi Pingxiang Feiyun Ceramics Co., Ltd.;

[0026] 2. Pour the above-mentioned loaded porous ceramsite into the concrete pool, dilute the cultivated activated sludge with water to a moisture content of 99.6% to 99.9%, spray it on the loaded ceramsite and mix evenly. Place it at a temperature of 20-35 for 7 days;

[0027] 3. Make the second-level and third-level packing according to the production method of the first-level packing. The treatment of the second-stage activated ...

Embodiment 2

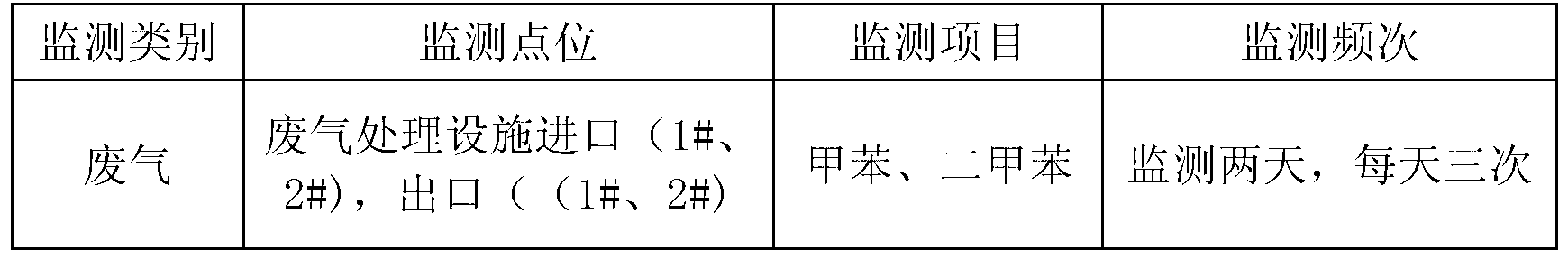

[0032] Spraying workshop's

[0033]

[0034] Executive standard

[0035] Exhaust gas emission implements the secondary standard in Table 2 of "Comprehensive Emission of Air Pollutants" (GB16297-1996)

[0036] Pollutants Toluene Xylene Emission concentration limit (mg / m 3 ) 40 70 Emission rate limit (kg / h) 3.1 1.0

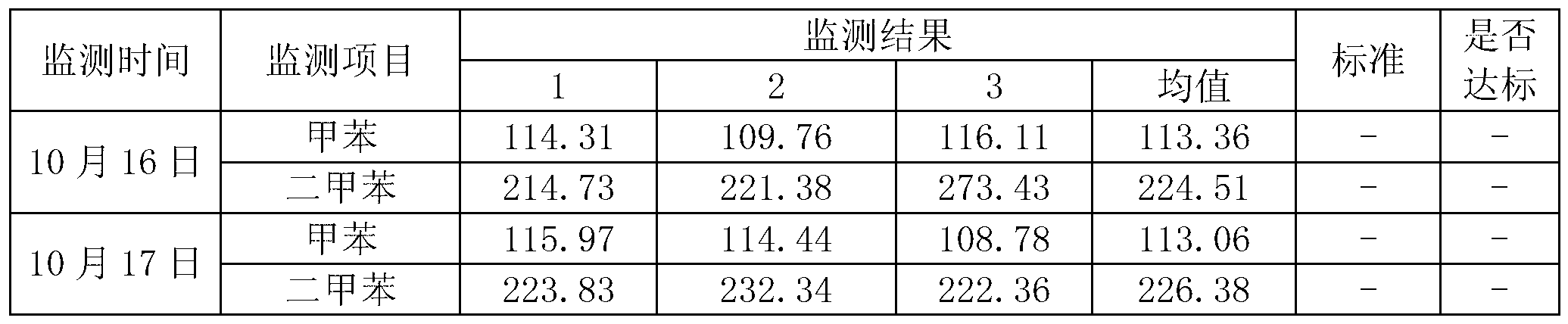

[0037] Monitoring results

[0038] The exhaust gas monitoring results and analysis are shown in the table below

[0039] Exhaust gas monitoring result table

[0040] Exhaust gas inlet 1# monitoring concentration result unit: mg / m 3

[0041]

[0042] Exhaust gas inlet 2# monitoring concentration result unit: mg / m 3

[0043]

[0044]

[0045] Exhaust gas outlet 1# monitoring concentration results Unit: mg / m 3

[0046]

[0047] Exhaust gas outlet 2# monitoring concentration results Unit: mg / m3

[0048]

[0049] Exhaust gas outlet monitoring rate results

[0050] Unit: kg / h

[0051]

[0052] The monitoring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com