High-precision cleanable security filter element and its application

A security filter and filter element technology, applied in ultrafiltration, chemical instruments and methods, semi-permeable membrane separation, etc., can solve the problems of difficult control of water quality, high filtration accuracy, and inability to clean, so as to improve the operation and replacement cycle. , the effect of reducing labor intensity and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Prepare and adopt the security filter element of the present invention:

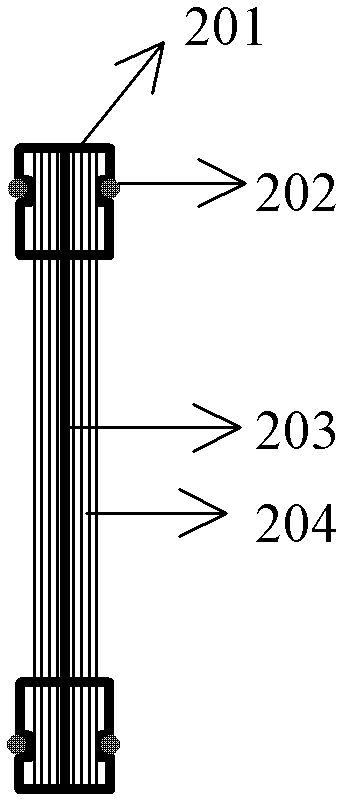

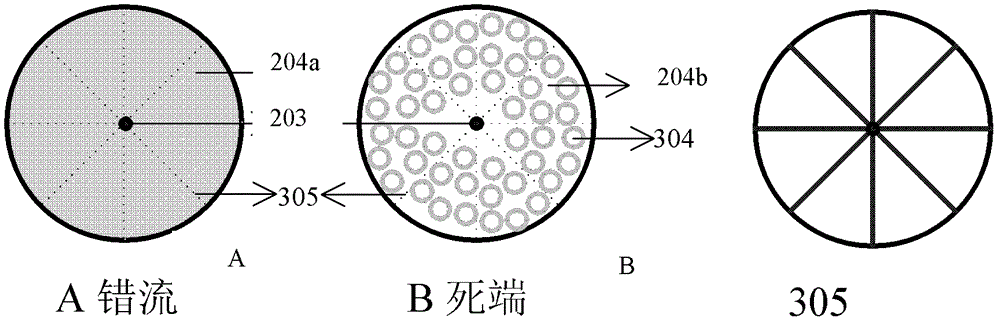

[0054] 1) Take a microfiltration membrane with an average pore size of 1 μm and a PTFE hollow fiber membrane with a pore size distribution range of 0.5-1.5 μm as the filter material, divide it into eight parts and distribute them evenly around the support column in the membrane filament end-blocking distributor, And control the two ends of the membrane filament to exceed the two ends of the membrane filament sealing distributor by about 10mm;

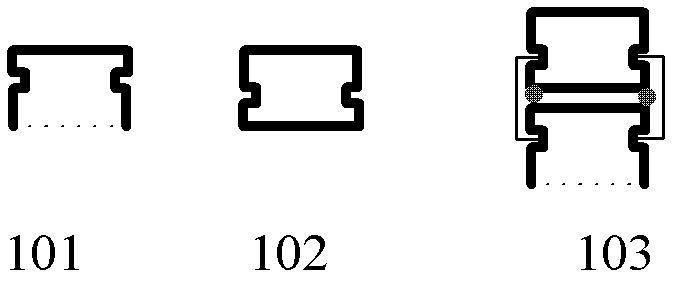

[0055] 2) Connect one end of the end-blocking distributor of membrane filaments distributed in step (1) to the casting end cover 102 and then fix it upright. For the connection method, see figure 1 shown;

[0056] 3) Prepare anhydrous calcium sulfate paste according to the mass ratio of deionized water to anhydrous calcium sulfate 1.8:1, and quickly transfer the calcium sulfate paste to the capping and casting cover in step (2), the immersion height is 3m...

Embodiment 2

[0071] Prepare and adopt the security filter element of the present invention:

[0072] 1) Take the microfiltration membrane with an average pore size of 0.5 μm, and the hydrophilic modified PVC hollow fiber microfiltration membrane with a pore size distribution range of 0.1-1.0 μm as the security filter material, divide it into eight parts and evenly distribute them to the membrane silk seal Around the supporting column in the end distributor, and control the two ends of the membrane filament to exceed the two ends of the membrane filament end distributor by 5mm;

[0073] 2) Connect one end of the end-sealed distributor of membrane filaments distributed in step (1) to the casting end cover and then fix it upright. For the connection method, see figure 1 as shown in 103 in;

[0074] 3) Prepare anhydrous calcium sulfate paste according to the mass ratio of deionized water to anhydrous calcium sulfate 2.2:1.6, and quickly transfer the calcium sulfate paste to the capping and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com