Method for carrying out surface modification on quantum dot/rod, preparation of photosynthetic catalyst as well as system and method

A modification and quantum dot technology, applied in the chemical industry, can solve problems such as complex extraction or synthesis, lack of surface catalytic sites, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

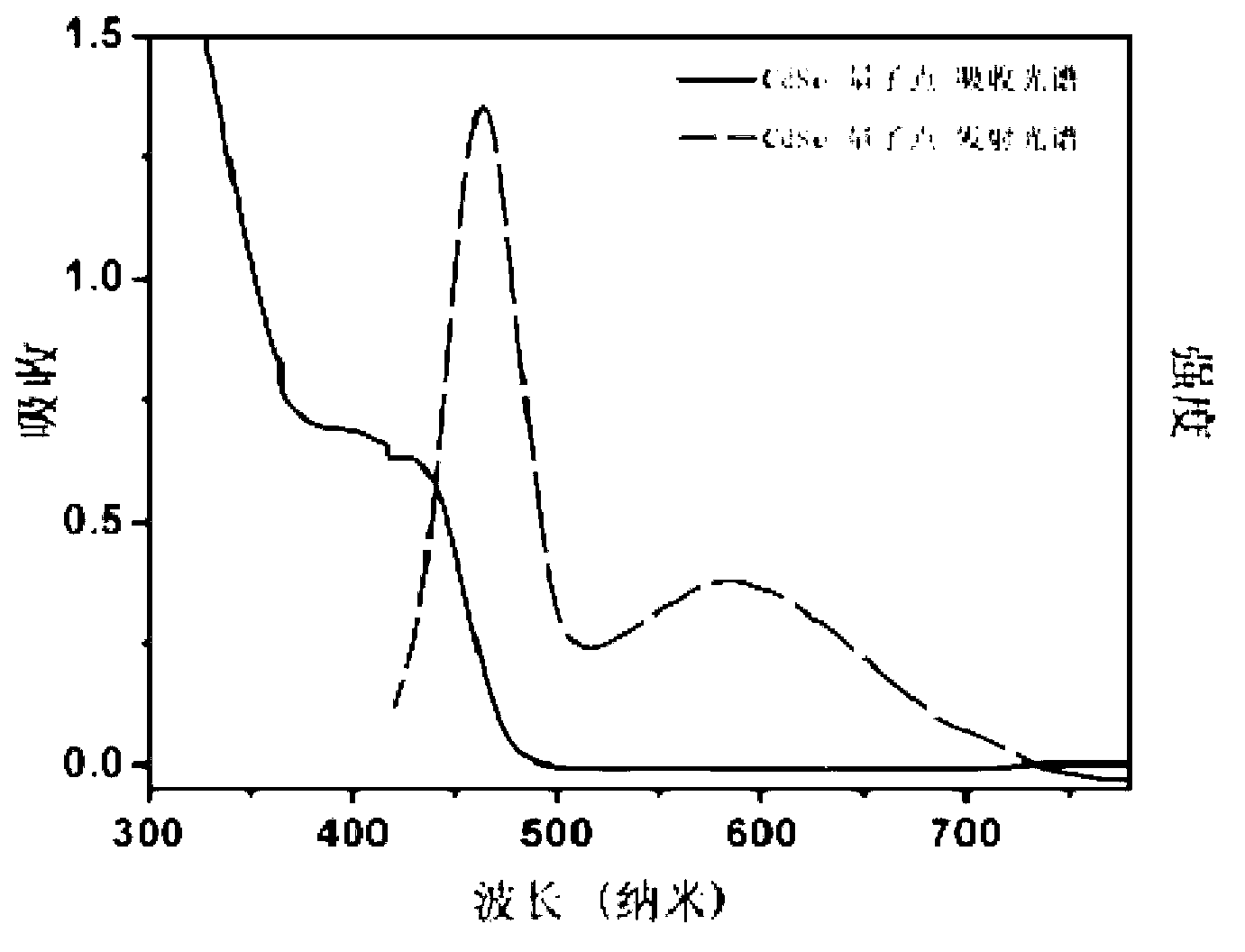

[0130] Synthesis of oil-soluble CdSe quantum dots:

[0131] Add 0.06g CdO, 0.28g octylated diphenylamine (abbreviation: ODPA), 3g tri-n-octylphosphine oxide (abbreviation: TOPO) into a 25ml three-neck flask, heat to 300°C under Ar atmosphere, and dissolve CdO until the solution is clear Transparent, inject 1.5g trioctylphosphine (abbreviation: TOP), the temperature rises to 350°C, inject Se precursor (0.058g Se+0.36g TOP), [Cd]:[Se] (molar ratio) = 0.64, The reaction was stopped after 5s to obtain CdSe seeds with a diameter of about 2.6nm. Using the method of alcohol precipitation, it was precipitated, centrifuged, and the liquid was poured out, and then the precipitate was dissolved in chloroform. Quantum dots of different sizes can be obtained by changing the ratio and temperature of the precursors.

Embodiment 2

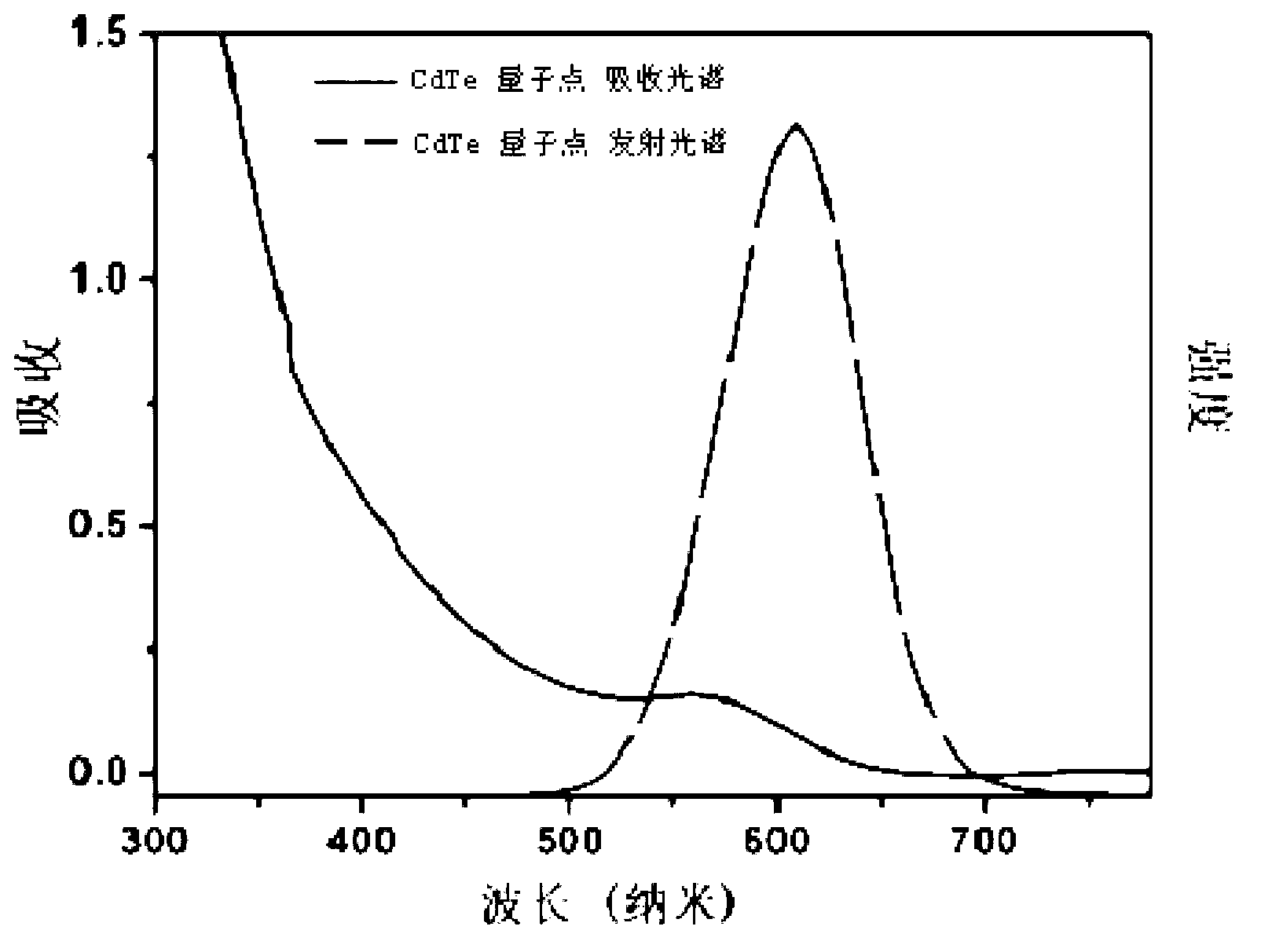

[0133] Synthesis of oil-soluble CdSe / CdS core-shell nanorods:

[0134] The CdSe seeds synthesized in Example 1 above can be further used to synthesize CdSe / CdS core-shell nanorods: 0.29g ODPA, 0.08g hydroxypropyl acrylate (abbreviation: HPA), 0.06g CdO and 3g TOPO were added to a 25ml three-necked flask , heated to 300°C under Ar atmosphere, CdO was dissolved until the solution was clear, 1.5g TOP was added, the temperature was raised to 350°C, and 0.8umol of CdSe seeds and S precursor (0.12g S+0.15g TOP) were quickly injected, and after 8mins The heating was stopped, and the nanorods were precipitated by alcohol precipitation, and then dissolved in chloroform for other uses. Different sizes of core-shell quantum rods can be obtained by changing the ratio and temperature of the precursors.

Embodiment 3

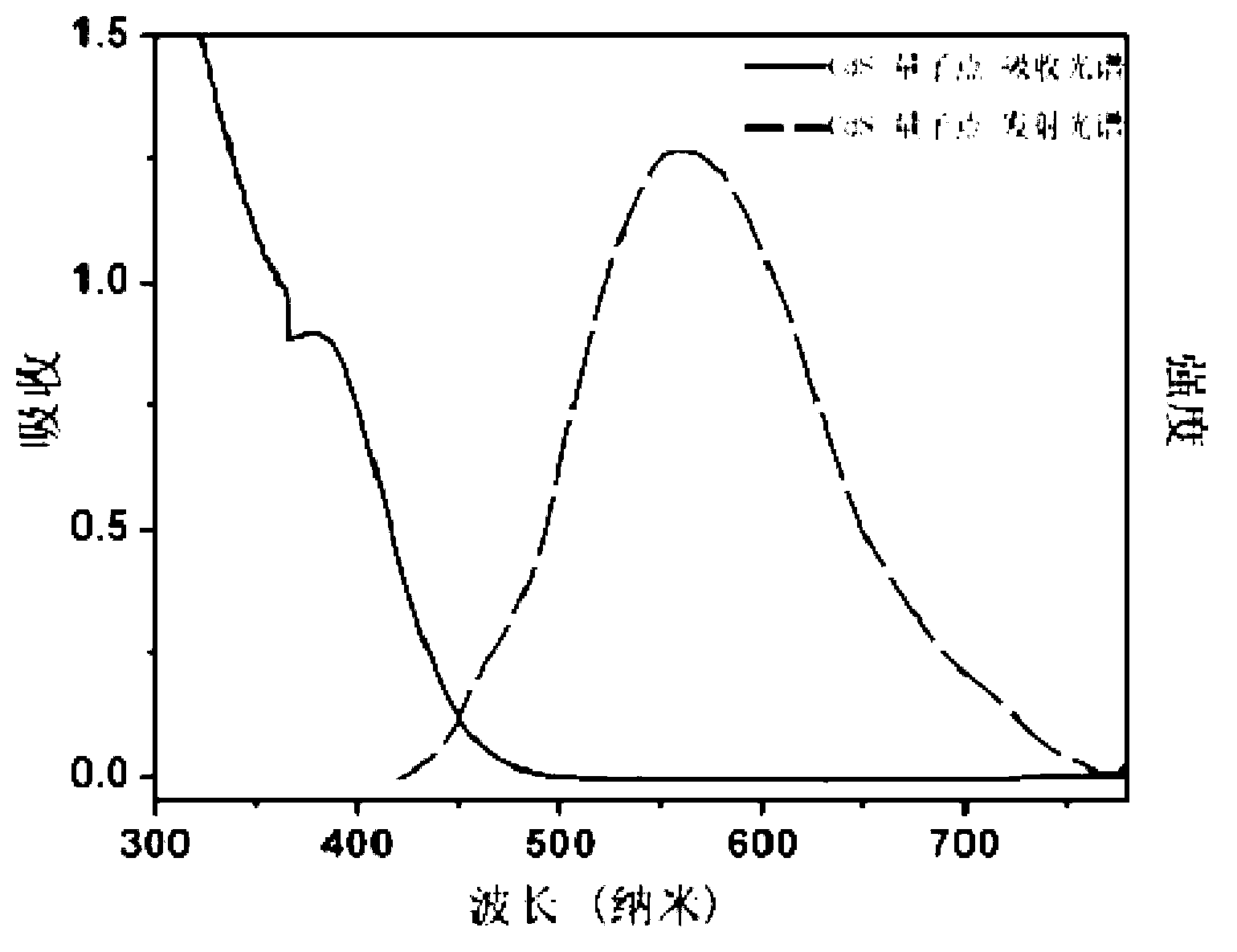

[0136] Synthesis of oil-soluble CdSe quantum rods:

[0137] Add CdO, n-tetradecylphosphoric acid (hereinafter referred to as: TDPA), n-dodecylamine (hereinafter referred to as: DDA) and TOPO of the quality listed in the following table into a 50ml three-necked flask, and connect the air condenser, The Ar gas was exhausted for 15 min, and the system was heated to 315° C. under Ar atmosphere. The system will dissolve slowly, and the color will change from brown-red to clear and transparent light yellow.

[0138] While the above system is heating, prepare TOPSe according to the configuration in the table below (selenium powder is dissolved in TOP, it needs to be heated to about 300°C). After the above system is clear and transparent, inject TOP and TOPSe into the system, and the temperature of the system drops to 260°C or so, continue to grow CdSe QDs at 270 °C. [Cd]:[Se]=1.6 Quantum dots grow faster in the early stage. If you want to observe their growth changes, you should ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com