Treatment method of thermoelectric materials before welding

A processing method and thermoelectric technology, applied in welding equipment, metal material coating process, liquid chemical plating, etc., can solve the problem of reducing the reliability and life of thermoelectric refrigeration components, limiting the application range of thermoelectric refrigeration components, It is difficult to obtain a wide range of applications and other problems to achieve good wettability and physical and chemical stability, ensuring physical stability and mechanical strength, and the effect of strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

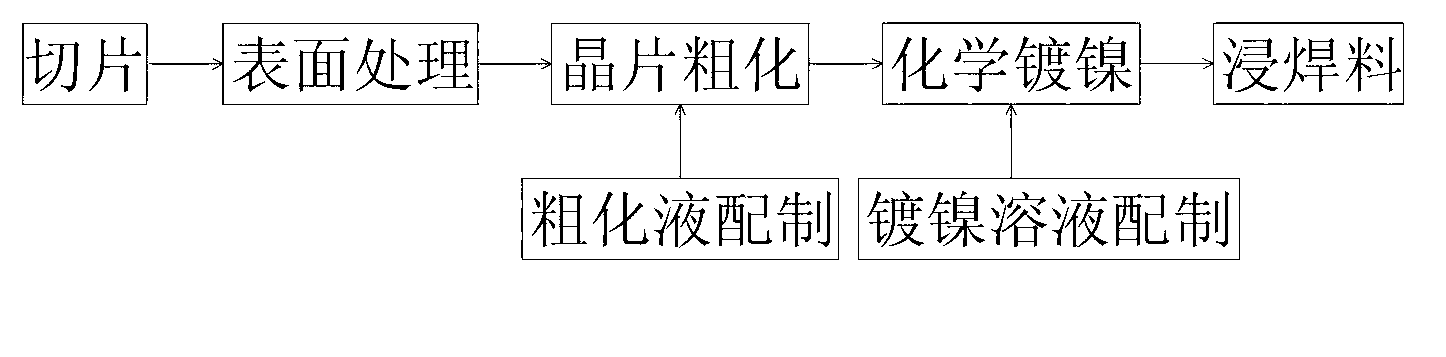

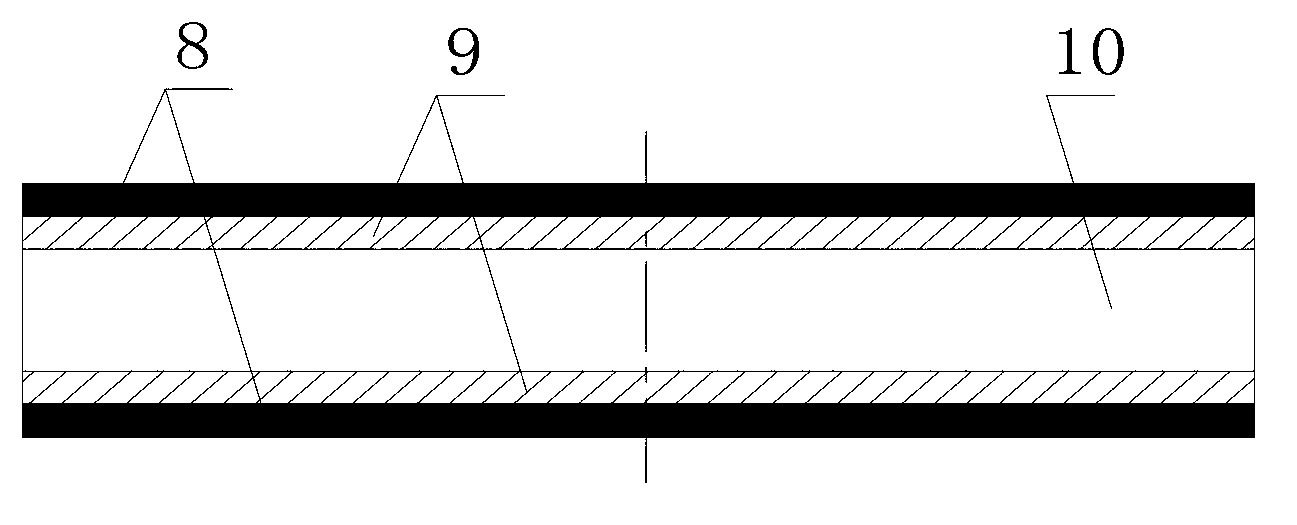

[0040] Refer to attached figure 1 , using a wire cutting machine to cut the N-type thermoelectric material and the P-type thermoelectric material into a required thickness of the thermoelectric material sheet 10 with a tolerance of ±0.015mm, and then perform surface treatment, roughening, and chemical plating on the thermoelectric material sheet respectively. Nickel and immersion solder, the specific steps are as follows:

[0041] Step 1. Surface treatment:

[0042] ⑴ High temperature alkali washing

[0043] Weigh 60g of sodium hydroxide and put in 1000ml of deionized water to make an aqueous solution of sodium hydroxide, heat the aqueous solution of sodium hydroxide to 80°C, and wash the thermoelectric material sheet with alkali for 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com