Dispersant and preparation method thereof, and application of dispersant in anionic polyacrylamide water-dispersible emulsion polymerization

A dispersant and copolymerization reaction technology, which is applied in the field of water-soluble polymer synthesis, can solve the problems of unfavorable long-term storage stability of water-dispersed emulsion, reduction of adsorption rate and stabilization, high viscosity of dispersant molecular weight system, etc., to improve long-term storage Stability, fast dissolution rate, improved dispersion and stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

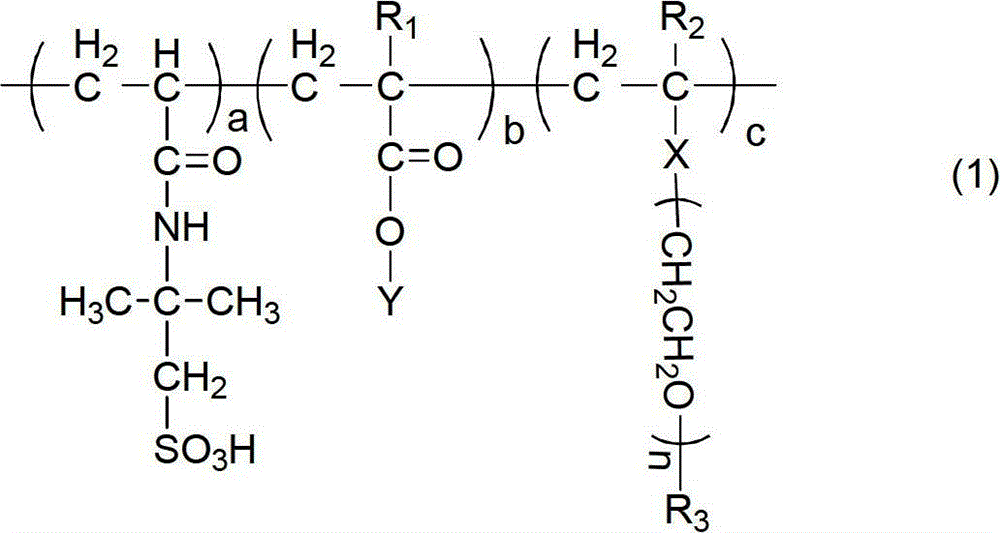

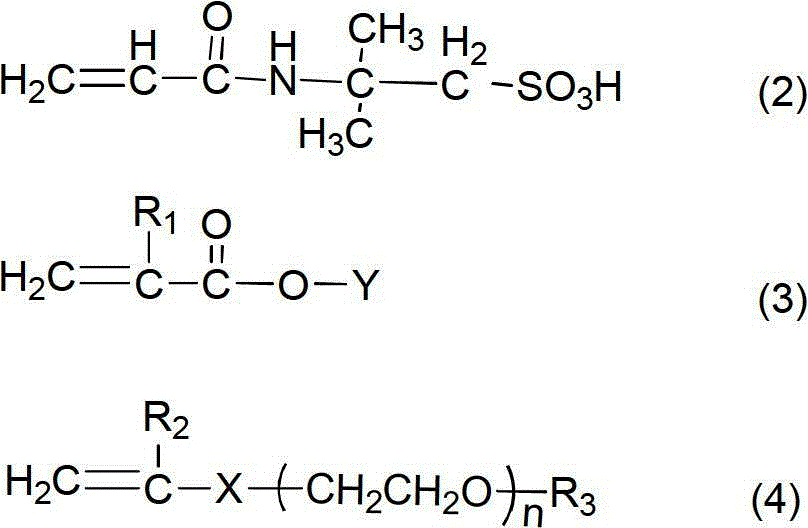

Method used

Image

Examples

Synthetic example 1

[0055] Synthesis Example 1 (Synthesis of Dispersant D-1)

[0056] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, a nitrogen inlet tube and a reflux condenser, add 100 milliliters of deionized water, purging the reaction vessel with nitrogen while stirring, and raising the temperature to 75 ° C, and then 30 grams of (B-4) and 7 grams of (B-1) and 5 grams of (F-1) and 80 milliliters of water to make a mixed monomer aqueous solution, which is dropped into the reactor for 2 hours, and Simultaneously, 20 grams of 10% ammonium persulfate initiator solution was added dropwise for 5 hours. After the dropwise addition, the solution was incubated and reacted for 5 hours and cooled to room temperature to obtain dispersant D-1 with a molecular weight of 15,000.

Synthetic example 2-4

[0057] Synthesis Example 2-4 (Synthesis of Dispersant D-2-D-4)

[0058] D-2-D-4 of the present invention was prepared according to the steps of Synthesis Example 1, and the ratios described in Table 2 were used for feeding.

[0059] The feeding ratio and molecular weight of table 2 dispersant preparation

[0060]

[0061] The embodiment is the synthesis method of the anionic polyacrylamide water-dispersed emulsion of the present invention.

Embodiment 1

[0062] Embodiment 1 (synthesis of APD-1)

[0063] In a glass reactor equipped with a thermometer, stirrer, nitrogen inlet tube and reflux condenser, add 59.84 grams of (A-1), 15.16 grams of (B-1), 100 grams of (C-1) and 5 grams of (C -4), 5 grams of (D-1) and 315 grams of deionized water, adjust the pH of the system to be 6 to 7, purge the reaction vessel with nitrogen while stirring, and heat up to 35 ° C, then add 0.020 grams of (I- 1), heat preservation reaction for 10 hours and then cool to room temperature to obtain anionic polyacrylamide water-dispersed emulsion APD-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com