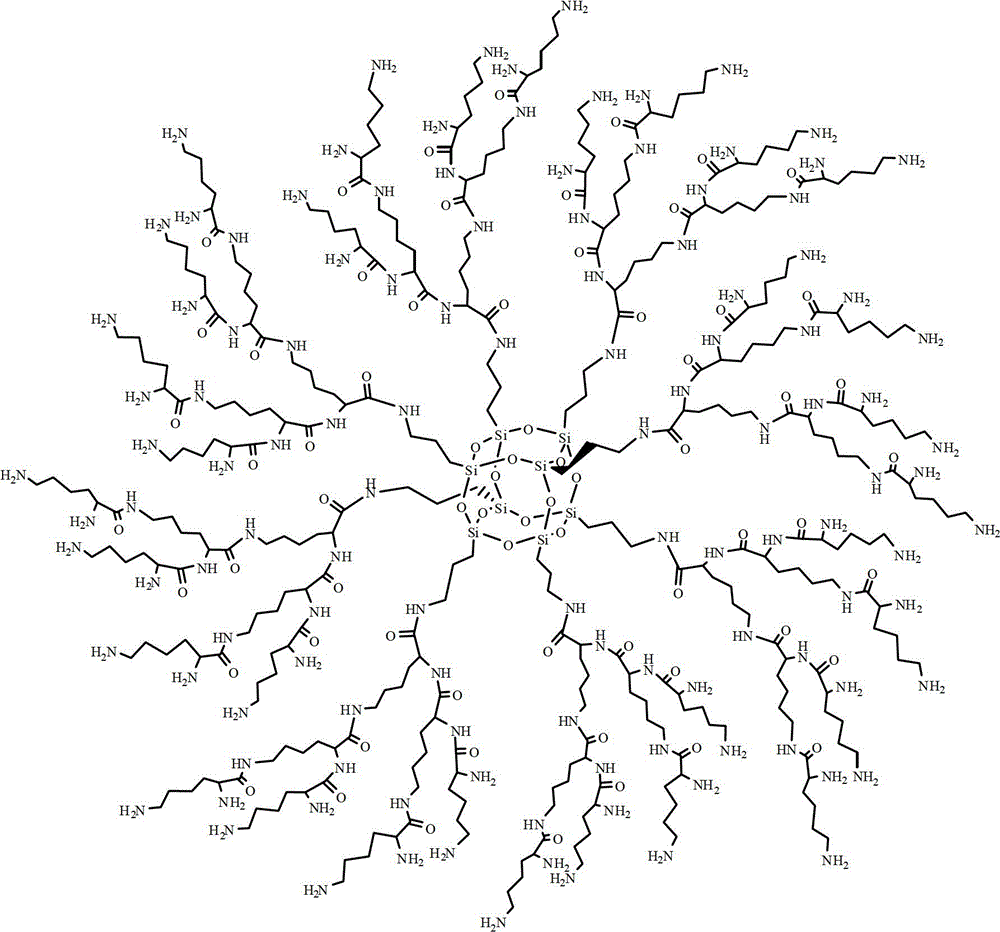

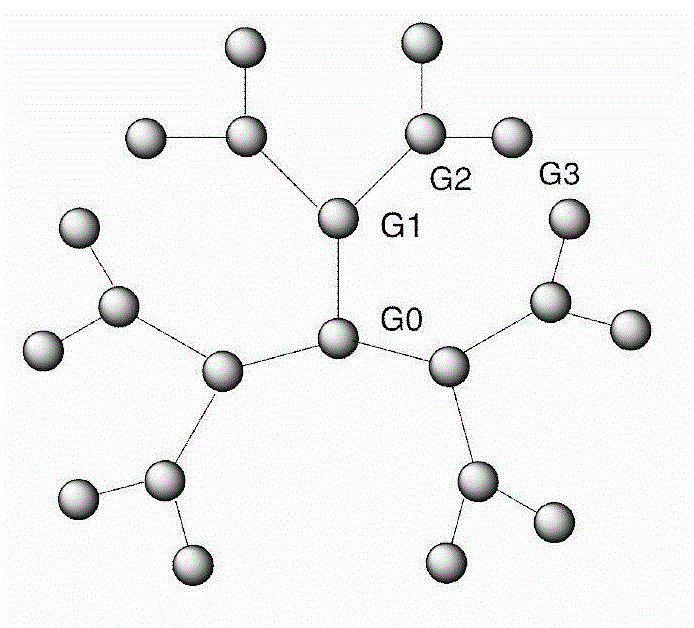

Synthesis method of dendriform compound trifluoroacetate using cage-type octamer (gamma-aminopropyl)silsesquioxane as core

A technology of trifluoroacetate and silsesquioxane, which is applied in the field of synthesis of dendrimer trifluoroacetate (G3(OL) trifluoroacetate), achieves less pollution, less species and higher yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Dissolve OAS hydrochloride (0.50g, 0.43mmol) and DIPEA (0.89g, 6.88mmol) in 20ml DMF, stir for 30min, then add N,N'-di-tert-butoxy in 30ml DMF drop by drop Carbonyl-L-lysine N-succinimide ester (3.05g, 6.88mmol), stirred at room temperature for 12 hours. After the reaction was completed, 150ml of acetonitrile chilled to 0°C was added, filtered, and the resulting solid was vacuum-dried at room temperature for 24 hours to obtain tert-butoxycarbonyl-protected G1(OL) (1.21g, 0.34mmol), with a yield of 80%.

[0024] 2. Add tert-butoxycarbonyl-protected G1(OL) (1.02g, 0.29mmol) into trifluoroacetic acid (5ml) chilled to 0°C and stir for 4 hours. After the reaction was completed, the reaction mixture was added to 50 ml of diethyl ether cooled to 0°C, and the precipitate was collected by filtration to obtain 0.80 g (0.21 mmol) of G1(OL) trifluoroacetate, with a yield of 74%.

[0025] 3. Using G1(OL) trifluoroacetate as raw material, adjust the molar ratio of G1(OL), DIPEA a...

Embodiment 2

[0028]1. Dissolve OAS hydrochloride (0.50g, 0.43mmol) and DIPEA (0.89g, 6.88mmol) in 20ml DMF, stir for 30min, then add N,N'-di-tert-butoxy in 30ml DMF drop by drop Carbonyl-L-lysine pentafluorophenol ester (3.52g, 6.88mmol), stirred and reacted at room temperature for 8 hours. After the reaction was completed, 150ml of acetonitrile chilled to 0°C was added, filtered, and the resulting solid was vacuum-dried to obtain tert-butoxycarbonyl-protected G1(OL) (1.28g, 0.37mmol), with a yield of 85%.

[0029] 2. Add tert-butoxycarbonyl-protected G1(OL) (1.02g, 0.29mmol) into trifluoroacetic acid (5ml) chilled to 0°C and stir for 4 hours. After the reaction was completed, the reaction mixture was added to 50 ml of diethyl ether cooled to 0°C, and the precipitate was collected by filtration to obtain 0.86 g (0.23 mmol) of G1(OL) trifluoroacetate, with a yield of 80%.

[0030] 3. Using G1(OL) trifluoroacetate as raw material, the molar ratio of G1(OL) trifluoroacetate, DIPEA and N,N-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com