Heat-resistant, flame resistant and anti-brittle fracture modified epoxy resin adhesive and preparation method thereof

A technology of epoxy resin and adhesive, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of unsuitable structural parts, fatigue resistance of adhesive parts, and limited application, etc., and achieve high practical value, Improved thermal stability and flame retardancy, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

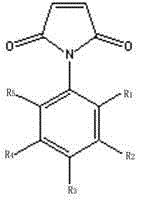

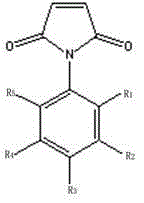

[0027] (1) Preparation of terpolymer of bromophenylmaleimide / styrene / glycidyl methacrylate

[0028] The mass composition is 25 grams of 2,4,6-tribromosubstituted phenylmaleimide, 60 grams of styrene, 15 grams of glycidyl methacrylate and 1,41 g of azobisisobutyronitrile dissolved in 500ml of 4-dioxane (the same below) is added to a reactor equipped with a stirrer, a thermometer and a nitrogen device, and the whole process is protected by nitrogen. A super constant temperature water bath was used to react at 70°C for 7 hours. After the reaction was completed, the reaction kettle was placed in an ice-water bath to terminate the reaction, and then the mixed solution was poured into a large amount of methanol, filtered with suction, and then used The oxane was dissolved and dispersed in methanol twice to remove unreacted monomers and oligomers, and dried in a vacuum oven at 60°C for 24 hours, and the obtained white powder was the target product.

[0029] (2) Preparation of heat-...

Embodiment 2

[0032] (1) Preparation of terpolymer of bromophenylmaleimide / styrene / glycidyl methacrylate

[0033] The mass composition is 30 grams of 2,5,6-tribromosubstituted phenylmaleimide, 40 grams of styrene, 30 grams of glycidyl methacrylate and 1,4- Dioxane was added into a reactor equipped with a stirrer, a thermometer and a nitrogen device, and the whole process was protected by nitrogen. A super constant temperature water bath was used to react at 75°C for 6.5 hours. After the reaction was completed, the reaction kettle was placed in an ice-water bath to terminate the reaction, and then the mixture was poured into a large amount of methanol, filtered with suction, and then 1,4-bis The oxane was dissolved and dispersed in methanol twice to remove unreacted monomers and oligomers, and dried in a vacuum oven at 60°C for 24 hours, and the obtained white powder was the target product.

[0034] (2) Preparation of heat-resistant, flame-retardant, and brittle-cracking-resistant modified ...

Embodiment 3

[0037](1) Preparation of terpolymer of bromophenylmaleimide / styrene / glycidyl methacrylate

[0038] The mass composition is 45 grams of 3,4-difluoro-2,5,6-tribromosubstituted phenylmaleimide, 30 grams of styrene, 25 grams of glycidyl methacrylate and dissolved azobisiso The 1,4-dioxane of butyronitrile is added to a reactor equipped with a stirrer, a thermometer and a nitrogen device, and the whole process is protected by nitrogen. Use a super constant temperature water bath to react at 80 °C for 6 hours. After the reaction is completed, place the reaction kettle in an ice-water bath to terminate the reaction, then pour the mixed solution into a large amount of methanol, filter it with suction, and then use 1,4-bis The oxane was dissolved and dispersed in methanol twice to remove unreacted monomers and oligomers, and dried in a vacuum oven at 60°C for 24 hours, and the obtained white powder was the target product.

[0039] (2) Preparation of heat-resistant, flame-retardant, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Onset thermal decomposition temperature | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com