1kV energy-saving type large-span high-conductivity low-noise weather-proof overhead insulation cable

An overhead insulated cable, high conductivity technology, applied in the direction of insulated cables, power cables for overhead applications, power cables, etc., can solve the waste of national resources and social labor, backward conductor materials and processing technology, and large damage caused by ultraviolet radiation. problems, to achieve the effect of low cost, reduced wire quality, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

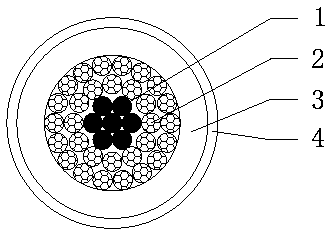

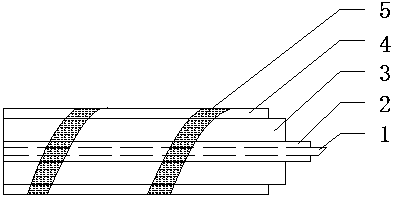

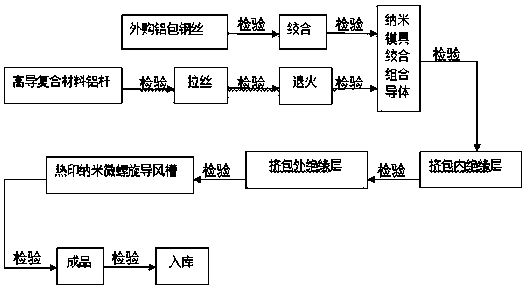

[0021] Such as Figure 1-2 As shown, a 1kV energy-saving large-span high-conductivity low-noise weather-resistant overhead insulated cable includes an aluminum-clad steel core reinforced core layer and a high-conductivity composite aluminum conductor layer, and the aluminum-clad steel core reinforced core layer and high-conductivity composite The aluminum conductor layer is combined into a composite conductor; the aluminum-clad steel core reinforcement core layer is composed of 7 aluminum-clad steel core reinforcement cores 1 arranged in the form of "1+6", and the high-conductivity composite aluminum conductor layer is composed of 12 The inner layer composed of 2 high-conductivity composite aluminum conductors and the outer layer composed of 18 high-conductivity composite aluminum conductors 2 are combined; the outer layers of the high-conductivity composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com