Insulated B1-level flame-retardant power cable

A power cable and flame retardant technology, which is applied in the field of insulating B1 flame retardant power cables, can solve the problems of scratch resistance, environmental hazards, high heat release rate, etc., achieve good lipophilicity and dispersion, and ensure safety Effective operation and improved dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

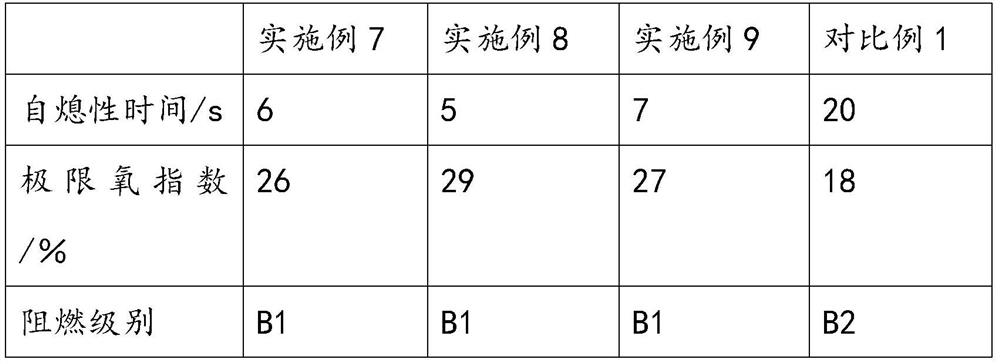

Examples

Embodiment 1

[0029] Preparation of flame retardant:

[0030] S1: Magnesium oxide plus deionized water, heated to 60°C by nitrogen bubbling method, adding sodium carbonate and ammonium chloride, placed in a constant temperature water bath oscillator, and controlling the ratio of magnesium oxide, sodium carbonate, and ammonium chloride to 3.5 g: 10g: 8g, shake for 3 hours, filter, wash the filter cake 4 times with 25mL of deionized water, wash 1 time with 15mL of absolute ethanol, dry at 120°C for 3 hours, and grind to obtain magnesium hydroxide powder;

[0031] S2: Add magnesium hydroxide powder to deionized water, then ultrasonically disperse to obtain a dispersion liquid, then dissolve the compound modifier with absolute ethanol and add it to the dispersion liquid to control the magnesium hydroxide powder and compound modification The dosage ratio of agent and absolute ethanol is 2.5g: 4g: 150mL, the temperature is raised to 80°C, stirred, and refluxed for 5h, then suction filtered, washe...

Embodiment 2

[0033] Preparation of flame retardant:

[0034] S1: Magnesium oxide plus deionized water, heated to 60°C by nitrogen bubbling method, adding sodium carbonate and ammonium chloride, placed in a constant temperature water bath oscillator, and controlling the ratio of magnesium oxide, sodium carbonate, and ammonium chloride to 3.5 g: 10g: 8g, shake for 3.5h, filter, wash the filter cake 4 times with 25mL of deionized water, wash 1 time with 15mL of absolute ethanol, dry at 120°C for 3h, and grind to obtain magnesium hydroxide powder;

[0035] S2: Add magnesium hydroxide powder to deionized water, then ultrasonically disperse to obtain a dispersion liquid, then dissolve the compound modifier with absolute ethanol and add it to the dispersion liquid to control the magnesium hydroxide powder and compound modification The dosage ratio of agent and absolute ethanol is 2.5g: 4g: 150mL, the temperature is raised to 80°C, stirred, and refluxed for 5h, then suction filtered, washed, place...

Embodiment 3

[0037] Preparation of flame retardant:

[0038] S1: Magnesium oxide plus deionized water, heated to 70°C using nitrogen bubbling method, adding sodium carbonate and ammonium chloride, placed in a constant temperature water bath oscillator, and controlling the ratio of magnesium oxide, sodium carbonate, and ammonium chloride to 3.5 g: 10g: 8g, shake for 4 hours, filter, wash the filter cake 5 times with 25mL of deionized water, wash 3 times with 15mL of absolute ethanol, dry at 120°C for 3 hours, and grind to obtain magnesium hydroxide powder;

[0039] S2: Add magnesium hydroxide powder to deionized water, then ultrasonically disperse to obtain a dispersion liquid, then dissolve the compound modifier with absolute ethanol and add it to the dispersion liquid to control the magnesium hydroxide powder and compound modification The dosage ratio of agent and absolute ethanol is 2.5g: 4g: 150mL, the temperature is raised to 85°C, stirred, and refluxed for 7h, then filtered, washed, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com