Decomposition method for sodium phenate of low-temperature coal tar

A low-temperature coal tar and sodium phenate technology, which is applied in tar processing, tar processing through distillation, and petroleum industry, can solve the problems of reducing the yield of coal tar hydrogenation to fuel, polluting the environment, and complex process flow, etc. To achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

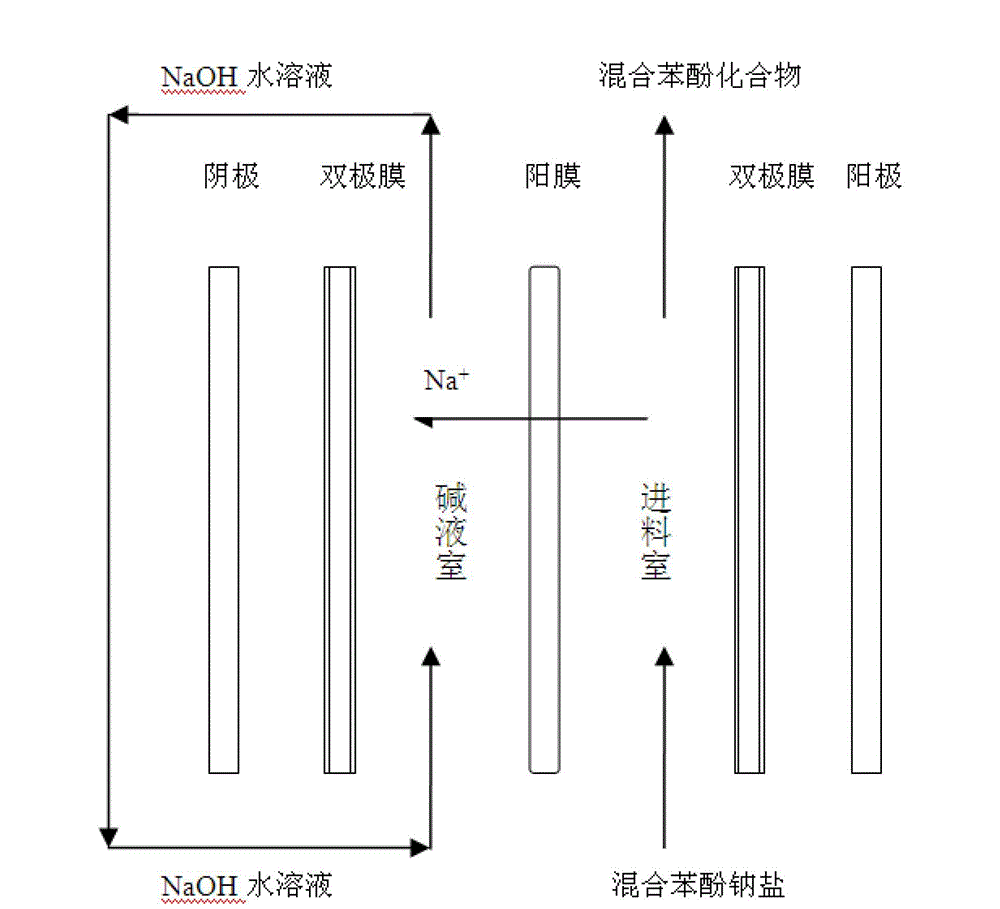

[0018] Such as figure 1 As shown, it is a bipolar membrane electrodialysis device adopted for the decomposition method of low-temperature coal tar phenolic sodium salt. The membrane device is composed of two bipolar membranes and a positive membrane as the basic unit, which is divided into an alkali solution chamber and a feed chamber. , the bipolar membrane is BP-1E membrane made in Japan, the positive membrane is FT-FKB membrane made in Germany, and the area of a single membrane is 0.02m 2 , The membrane spacing is 8mm. At both ends of the membrane are the cathode and the anode, which are connected to the two stages of the DC power supply. The concentration of 40-60g / L sodium hydroxide aqueous solution is fed into the lye chamber, the circulating flow rate of the solution is 18-22mL / min, and the mixed phenol sodium salt solution obtained after alkali treatment of low-temperature coal tar distillation distillate oil is fed into the feed chamber, The solution concentration...

Embodiment

[0020] Weigh about 1 kg of low-temperature coal tar and put it into a laboratory atmospheric distillation device, add a small amount of zeolite into the flask, and heat and distill to obtain distillate oil with a boiling point less than 300°C. Add 100g of the distillate to 400g of 10% sodium hydroxide aqueous solution, heat to 50°C, stir and mix thoroughly, cool to room temperature, let stand to separate layers, separate the water phase, and mix the aqueous solution with a concentration of phenol sodium salt of 102g / L.

[0021] A bipolar membrane electrodialysis device such as figure 1 As shown, the membrane device is composed of two bipolar membranes and a positive membrane as the basic unit, which is divided into a feed chamber and an alkali solution chamber. The bipolar membrane is a BP-1E membrane made in Japan, and the positive membrane is FT made in Germany. -FKB type membrane, single membrane area is 0.02m 2 , The membrane spacing is 8mm. The sodium hydroxide aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com