Agricultural waste pyrolyzing furnace

A technology of agricultural waste and pyrolysis furnace, which is applied in the field of pyrolysis furnace, can solve the problems of unsuitable for comprehensive conversion and utilization of waste, difficult operation of the structure, poor economic benefits, etc., and achieve improved working conditions, lower temperature, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

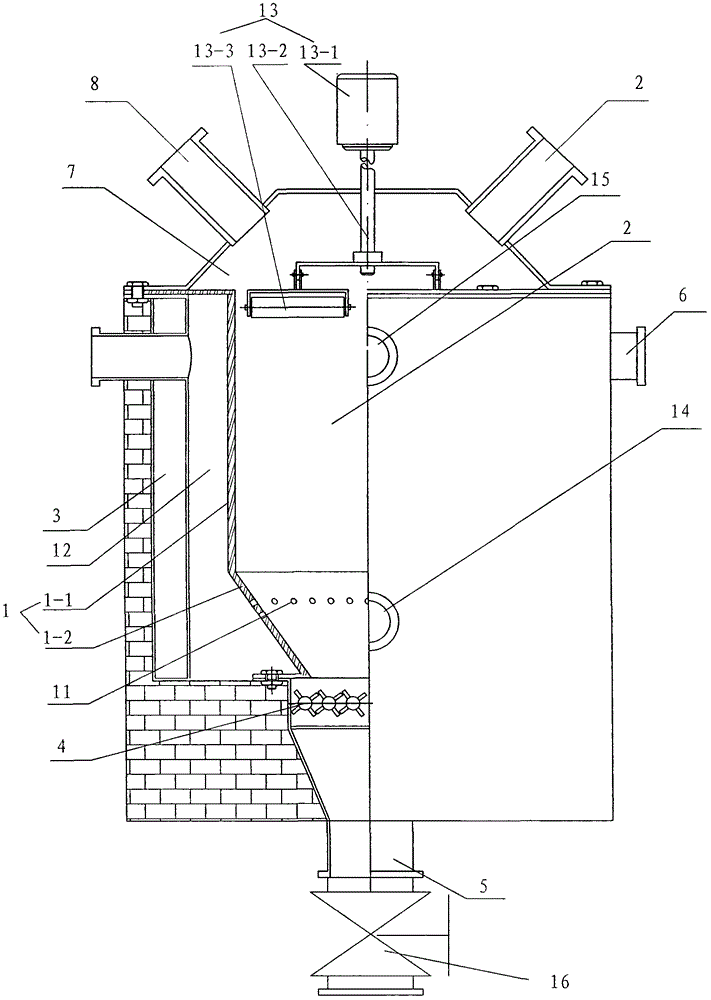

[0022] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the structure, features and effects of the agricultural waste pyrolysis furnace proposed in accordance with the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments. The instructions are as follows.

[0023] See figure 1 As shown, the agricultural waste pyrolysis furnace of the preferred embodiment of the present invention includes: a steel inner tube 1, an outer tube 3 arranged outside the inner tube 1, a grate 4, a discharge port 5, an air outlet pipe 6, a set The furnace cover 7 on the upper mouth of the inner cylinder 1, the feed port 8 and the air inlet 2 provided on the furnace cover 7, wherein the bottom of the inner cylinder 1 is connected to the discharge port 5, and the grate 4 is provided at Between the inner cylinder 1 and the discharge port 5; the lower cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com