Preparation method and device of thermally cracking biomass into gas in high-temperature and flash mode

A preparation device and biomass technology, applied in the direction of manufacturing combustible gas, educts, special forms of dry distillation, etc., can solve the problems of high production cost, high energy consumption, secondary pollution of catalysts, etc., and achieve low production cost and economical Effect beyond benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

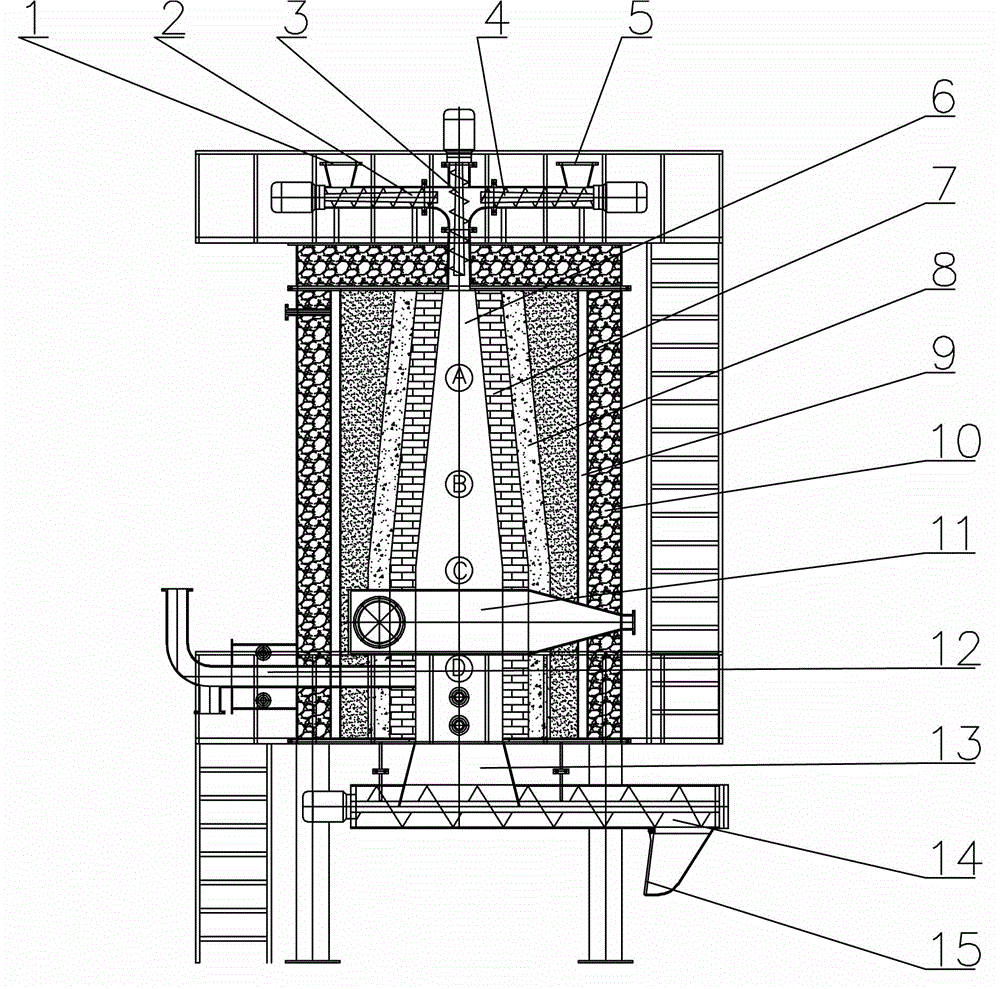

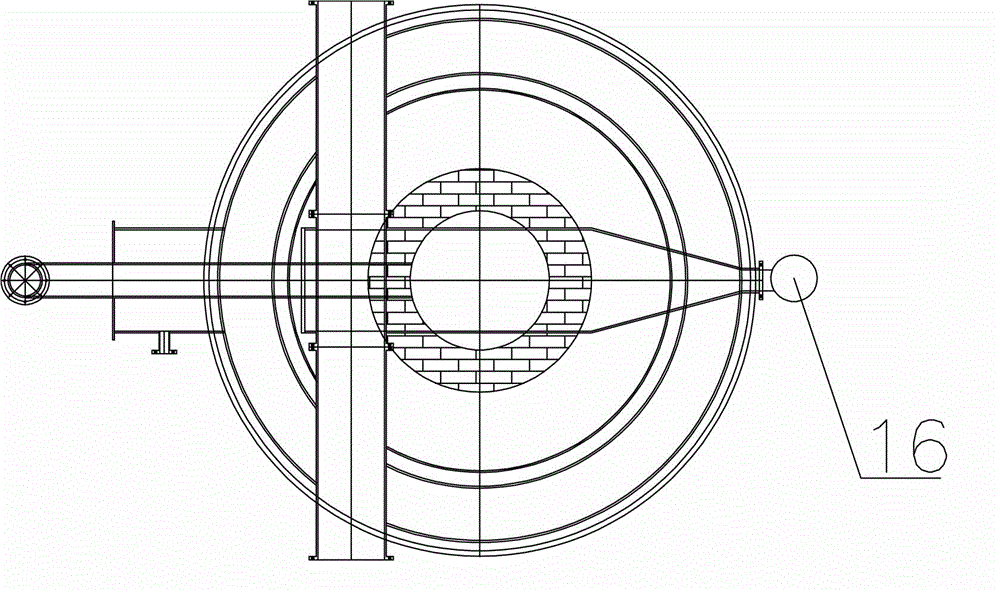

[0032] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

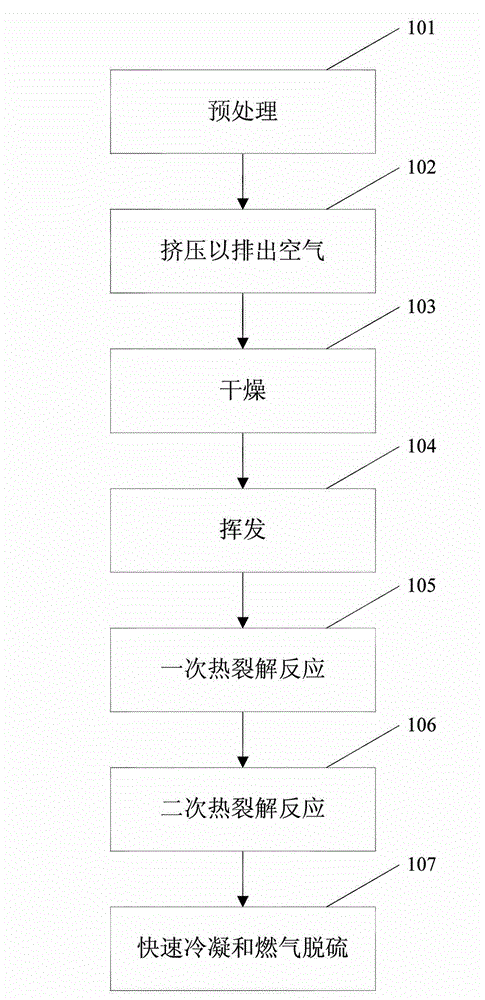

[0033] figure 1It is a flowchart of a preferred embodiment of the preparation method of high-temperature flash pyrolysis of biomass into gas in the present invention. In step 101, the biomass is pretreated. In one embodiment, the pretreatment includes coarsely pulverizing the biomass and then drying, screening to remove dust, magnetic separation to remove metal, air separation to remove glass and masonry, and finally finely pulverizing the biomass. The process goes to step 102.

[0034] In step 102, the pretreated biomass is squeezed to remove air. In one embodiment, the biomass needs to be squeezed several times, for example, squeezed twice, so as to release as much air as possible. Squeeze the air out of the biomass because only the biomass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com