Spiral vibrating bed waste heat recovery device in melted blast furnace slag granulation process

A technology of waste heat recovery device and granulation process, which is applied in the direction of recycling technology, furnace, furnace components, etc., can solve the problems of increasing cooling air volume, increasing equipment size, and insufficient cooling speed, so as to extend the flow distance and reduce the Dimensions, effect of preventing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

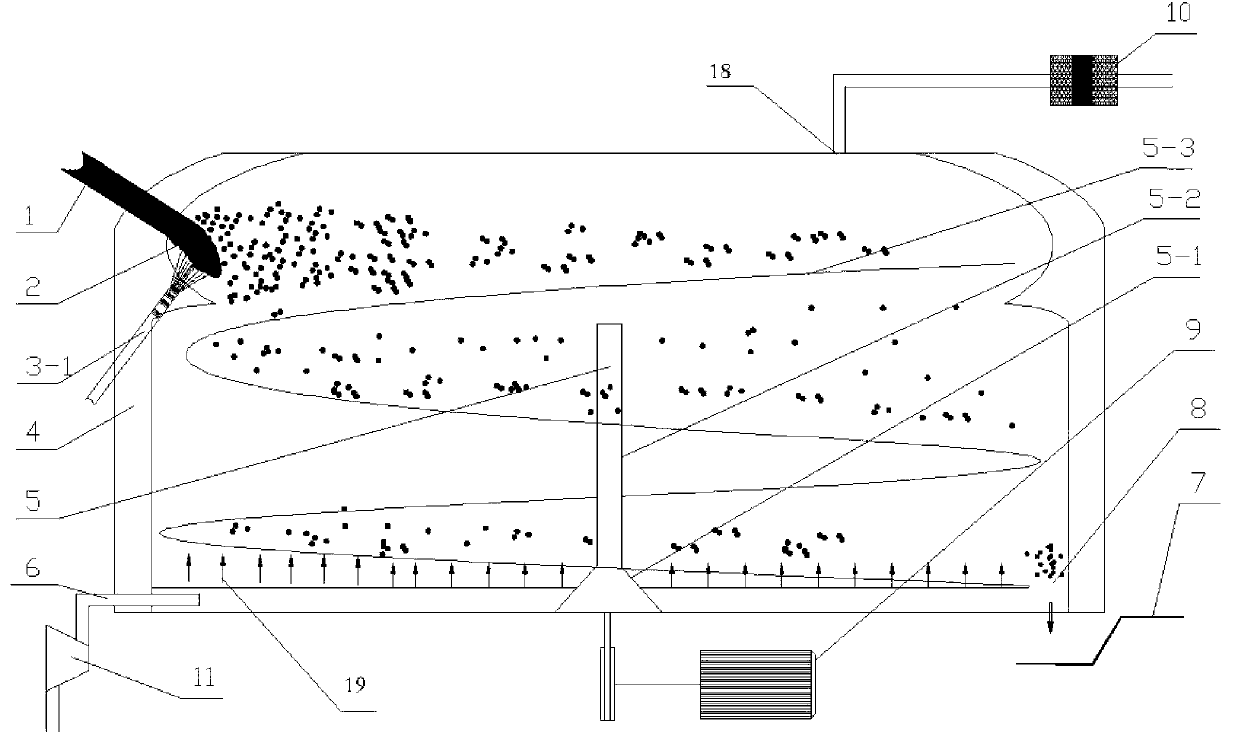

[0031] Specific implementation mode one: for the air quenching granulation treatment method, the attached figure 2As shown in the structural device, the molten slag 2 discharged from the blast furnace at about 1500°C enters the granulation chamber shell 4 of the granulation device through the draft pipe 1, and is broken into molten slag by the high-pressure gas stream injected from the nozzle 3-1. Slag particles, the slag particles pass through the spiral vibrating bed 5 during flight and landing, and are cooled by the cooling air at the bottom through the air pipe 6 to rapidly cool and prevent sticking. The particle outlet 8 flows to the slag particle conveying device 7 and is transported to the secondary cooling chamber 14; the high-temperature air after heat exchange is sprayed out through the high-temperature air outlet 18, and after being dedusted by the first dust collector 10, part of it is transported to the hot blast stove In 13, the other part is slowly transported ...

specific Embodiment approach 2

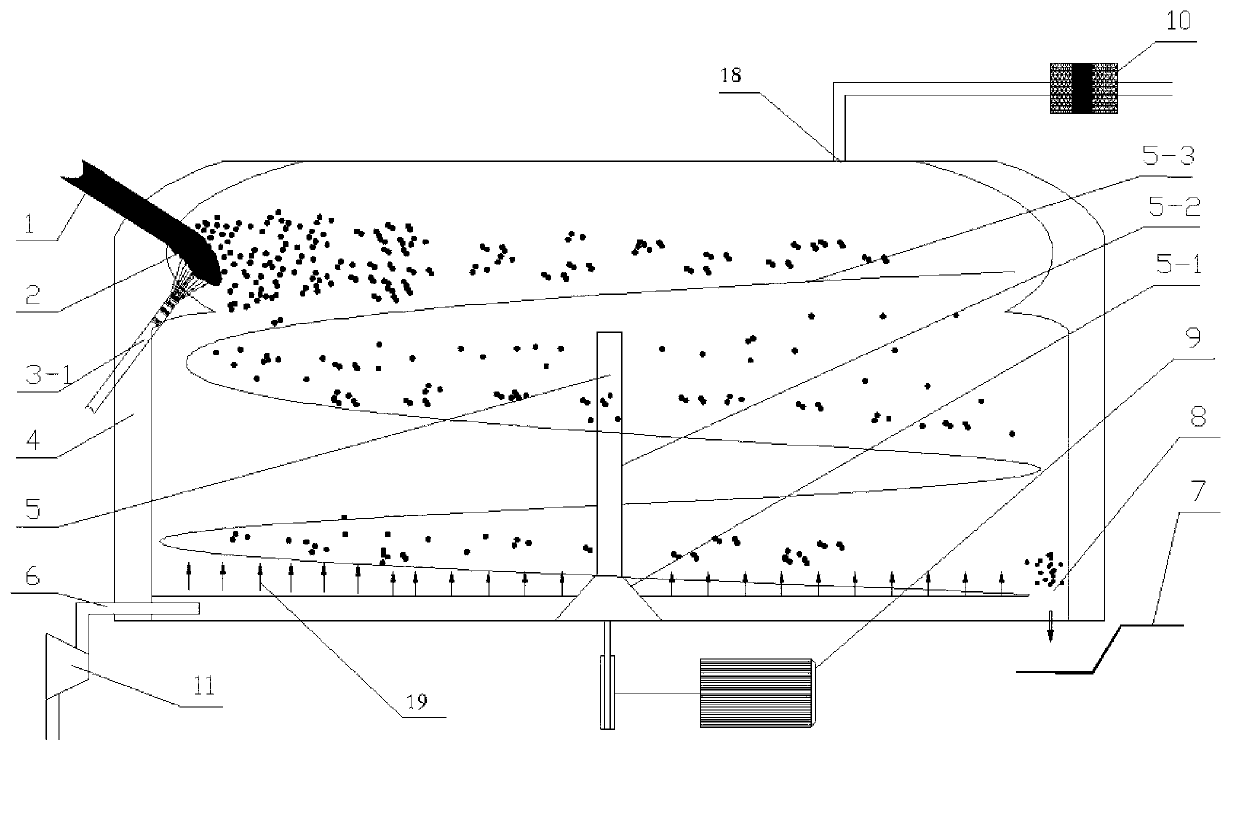

[0032] Specific implementation mode two: for the centrifugal granulation treatment method, adopt the attached image 3 As shown in the structural device, the molten slag 2 discharged from the blast furnace at about 1500°C enters the granulation device through the draft pipe 1, and is granulated and broken into molten slag particles by the centrifugal granulation device 3-2. The slag particles are flying and falling Through the spiral vibrating bed 5, through the bottom cooling, the cooling air passed through the air pipe 6 is rapidly cooled and prevented from sticking, and when the temperature of the slag particles drops to 850°C~1000°C, it flows to the slag particle conveying device 7 through the slag particle outlet 8 Transported to the secondary cooling chamber 14; the high-temperature air after heat exchange is sprayed out through the high-temperature air outlet 18, and after being dedusted by the first dust collector 10, part of it is transported to the hot blast stove 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com