A method for preparing titanium metal by continuous molten salt electrolysis

A technology of molten salt electrolysis and titanium metal, which is applied in the field of continuous molten salt electrolysis to prepare titanium metal, can solve the problems of non-continuous production, long process flow, and many procedures, and achieve fast diffusion speed, high current efficiency, and accelerated deoxidation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

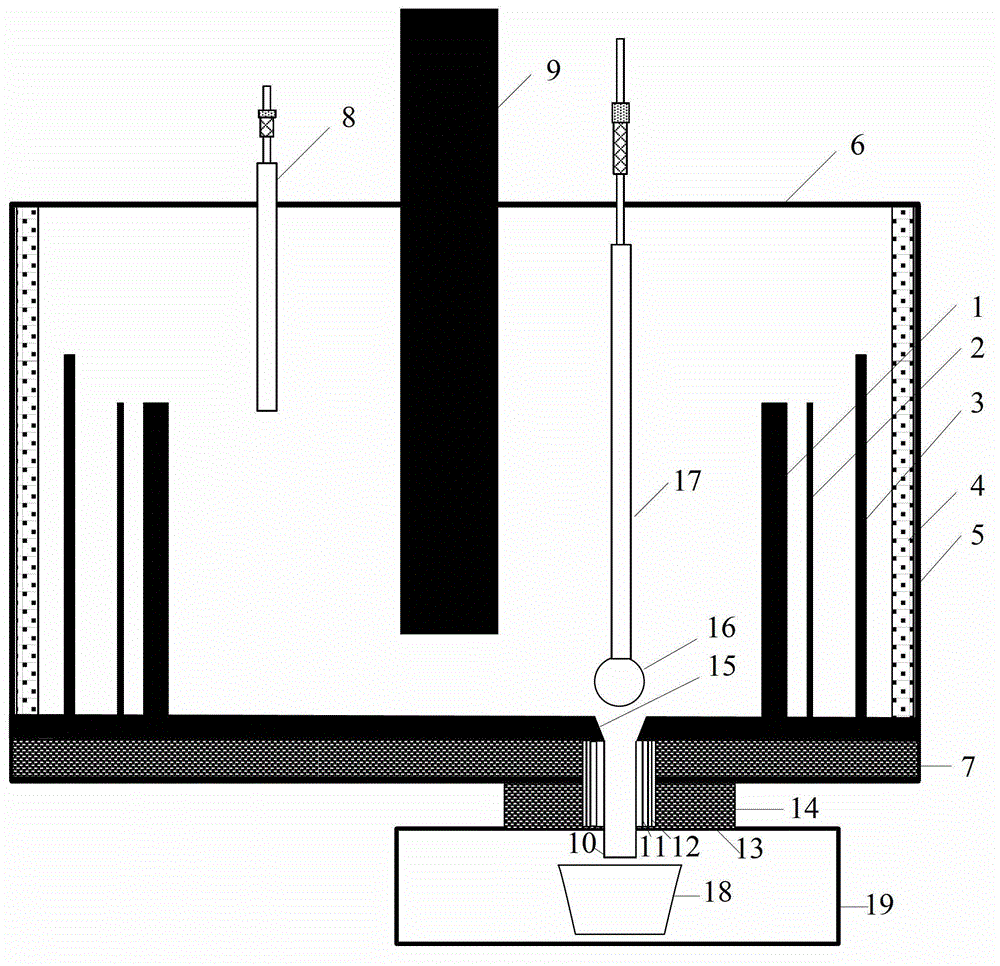

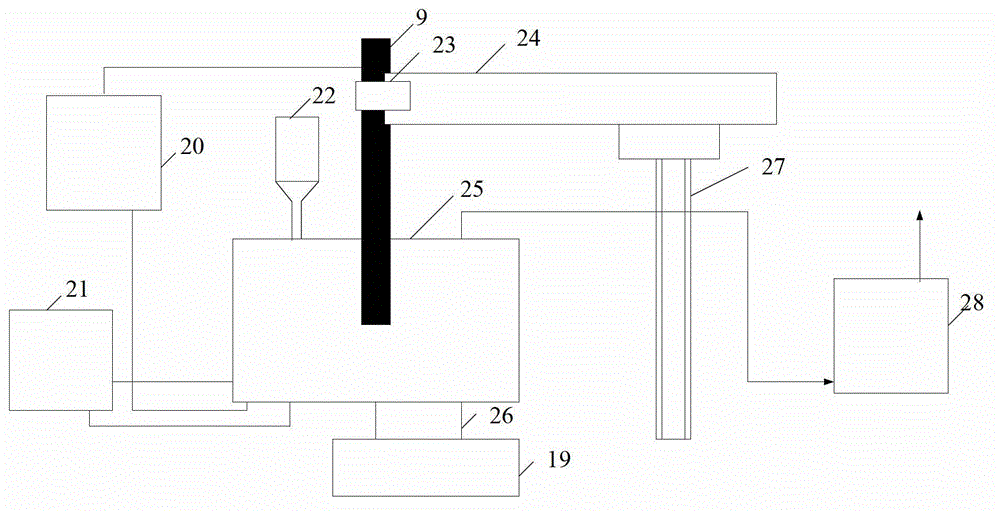

[0014] The titanium high-temperature electrolytic furnace system involved in the present invention mainly includes a high-temperature electrolytic furnace, a rectifier 20 , a transformer 21 , a conductive cross arm, a feeder 22 , and a tail gas treatment device 28 .

[0015] In this invention, the electrolysis chamber 25 mainly includes the molten pool 1, the heating element 2, the heat shield 3, the insulation cotton 4, the furnace shell 5 with the water cooling jacket and the furnace cover 6 with the water cooling jacket, wherein the electrolysis chamber 25 is Cuboid, 3m long, 1.5m wide, and 2m high. Refractory bricks 7 are laid on the bottom of the electrolytic chamber 25 . The molten pool 1 is rectangular, located in the center of the electrolysis chamber 25, made of graphite material, used as an electrolytic cell for high-temperature molten salt electrolysis, and also as a cathode for molten salt electrolysis during the electrolysis process. A heating element 2 is instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com