Method for preparing Ho-Fe alloy through molten salt electrolysis

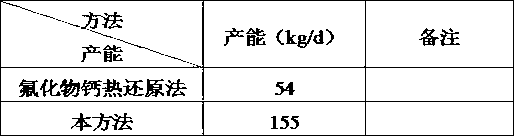

A technology of molten salt electrolysis and ferroalloy, which is applied in the field of preparation of holmium-iron alloy by molten salt electrolysis, which can solve the problems of high production cost, low production capacity and high production energy consumption, and achieve reduced energy consumption and production cost, high production capacity and reduced secondary refining the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A 500mm circular graphite electrolytic cell is used, the electrolytic cell is placed in a small steel sleeve, surrounded by graphite powder, the upper part is sealed with refractory cement, and the corundum gasket is installed, and then the small steel sleeve is placed in the steel furnace shell In the middle, the insulation materials, refractory materials and thermal insulation materials are filled around, and the cover plate is installed. The anode is composed of 4 graphite sheets, which specifically includes the following steps:

[0026] (1) First, the electrolytic cell is baked with an arc machine for 8 hours, and the furnace body is dried;

[0027] (2) Then turn on the power of the arcing machine to 45Kw, and continuously add a binary system electrolyte composed of holmium fluoride and lithium fluoride to the furnace. The electrolyte is as follows: the mass fraction of lithium fluoride is 3%, fluoride The mass fraction of holmium is 97%, which is prepared and added...

Embodiment 2

[0036] A 550mm circular graphite electrolytic cell is used, the electrolytic cell is placed in a small steel sleeve, filled with graphite powder, the upper part is sealed with refractory cement, and the corundum gasket is installed, and then the small steel sleeve is placed in the steel furnace shell In the middle, the insulation materials, refractory materials and thermal insulation materials are filled around, and the cover plate is installed. The anode is composed of 4 graphite sheets, which specifically includes the following steps:

[0037] Specifically include the following steps:

[0038] (1) First, use an arc striker or a heating element oven for 12 hours to dry the furnace body;

[0039] (2) Then turn on the power of the arcing machine to 45Kw, and continuously add a binary system electrolyte composed of holmium fluoride and lithium fluoride to the furnace. The electrolyte is as follows: the mass fraction of lithium fluoride is 15%, and the The mass fraction of holmi...

Embodiment 3

[0048] A 600mm circular graphite electrolytic cell is used, and the electrolytic cell is placed in a small steel sleeve, surrounded by graphite powder, sealed with refractory cement, and a corundum gasket is installed, and then the small steel sleeve is placed in the steel furnace shell In the middle, the insulation materials, refractory materials and thermal insulation materials are filled around, and the cover plate is installed. The anode is composed of 4 graphite sheets, which specifically includes the following steps:

[0049] (1) First, use an arc striker or a heating element oven for 24 hours to dry the furnace body;

[0050] (2) Then turn on the power of the arcing machine to 45Kw, and continuously add a binary system electrolyte composed of holmium fluoride and lithium fluoride to the furnace. The electrolyte is as follows: the mass fraction of lithium fluoride is 30%, and the The mass fraction of holmium is 70%, which is prepared and added to the electrolytic cell, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com