Graphene capacitive touch screen metal electrode fine patterning method

A capacitive touch screen, metal electrode technology, applied in metal material coating process, superimposed layer plating, electrical digital data processing and other directions, can solve the problem that the mask alignment accuracy and speed cannot meet the needs of normal production, reduce production Efficiency and product yield, low film conductivity and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] A fine patterning method for graphene capacitive touch screen metal electrodes, comprising the steps of:

[0096] (1) Prepare a single layer or 2~3 atomic layer graphene film on a glass substrate by CVD transfer method; CVD transfer method refers to the formation of 0.3~ 1.5nm thick graphene film, and then the graphene film layer is transferred to the substrate by chemical transfer method;

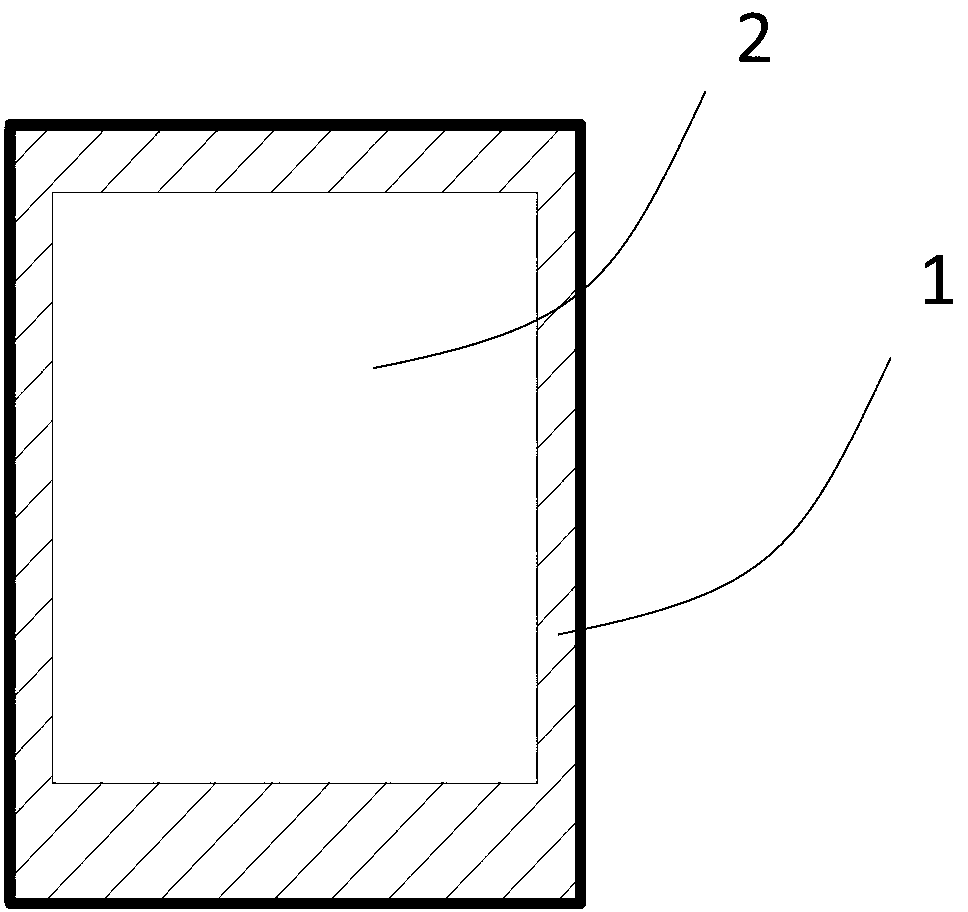

[0097] (2) Use the spin coating method to uniformly cover the positive photoresist on the graphene layer, combine with a suitable mask plate, and expose the lead electrode area (1) and the window touch area (2) through exposure and development;

[0098] (3) Deposit the lead metal layer on the graphene substrate by magnetron sputtering method, and the film thickness can be 200~1000nm;

[0099] (4) Using online roller brushing or manual wiping, the positive glue remover composed of ethanolamine and dimethyl sulfoxide removes the photosensitive glue / metal film layer, temperature contr...

Embodiment 2

[0102] A fine patterning method for graphene capacitive touch screen metal electrodes, comprising the steps of:

[0103] (1) Using the method disclosed in CN102220566A to prepare a graphene film, specifically: placing the copper foil substrate in a vacuum tube furnace, injecting hydrogen into the vacuum chamber while removing oxygen in the vacuum chamber, and raising the temperature to 1000°C , and then methane gas is injected into the vacuum chamber to obtain a metal substrate deposited with graphene; the thickness of the graphene film is 0.3nm;

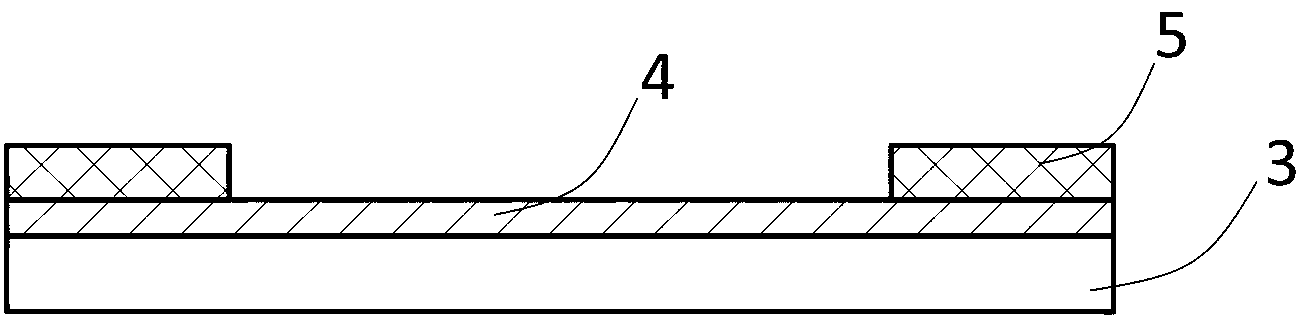

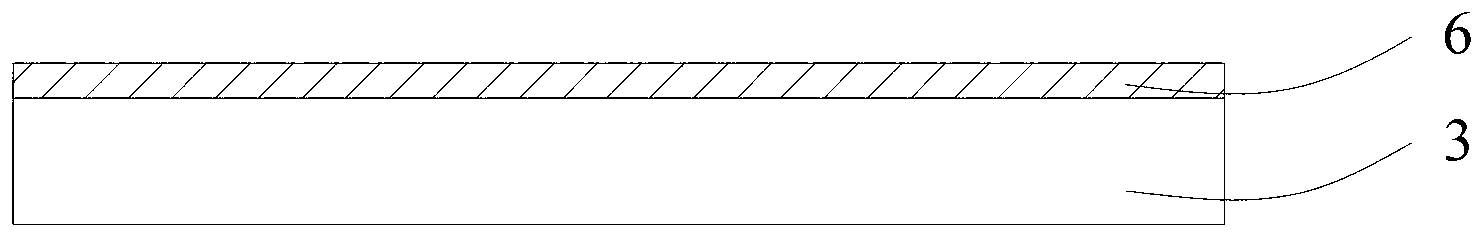

[0104] Then through the method of chemical transfer, using PDMS as the medium, the graphene film layer is transferred onto the substrate, and the whole board is obtained as the substrate I of the layered structure of graphene / substrate; the structure of the substrate I is as follows image 3 shown ( image 3 is a structural schematic diagram of the substrate 1 described in an embodiment of the present invention);

[0105] (2) Coat...

Embodiment 3

[0112] A fine patterning method for graphene capacitive touch screen metal electrodes, comprising the steps of:

[0113] (1) Using the method disclosed in CN102220566A to prepare a graphene film, specifically: placing the copper foil substrate in a vacuum tube furnace, injecting hydrogen into the vacuum chamber while removing oxygen in the vacuum chamber, and raising the temperature to 1000°C , and then methane gas is injected into the vacuum chamber to obtain a metal substrate deposited with graphene; the thickness of the graphene film is 1nm;

[0114]Then through the method of chemical transfer, with PMMA as the medium, the graphene thin film is transferred onto the glass substrate, and the graphene film layer is transferred onto the substrate to obtain the substrate I with a layered structure of graphene / substrate. ;

[0115] (2) Coating the positive photoresist evenly on the graphene layer of the substrate I to obtain the substrate II with a layered structure of photoresi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com