High voltage lithium ion battery anode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of metal ion loss and content, and achieve the effect of superior electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of LiNi by a new liquid phase method 0.5 mn 1.5 o 4 Cathode material

[0042] 1) According to the chemical formula LiNi of the target product 0.5 mn 1.5 o 4 , Weigh manganese sulfate and nickel sulfate according to the metering ratio of 1:3, and prepare an aqueous solution A with a total concentration of Ni and Mn ions of 0.5mol / L;

[0043] 2) Heat the aqueous solution A prepared above to 70°C in a water bath, and adjust the pH value of the solution to 7 with dilute sulfuric acid and ammonia water;

[0044] 3) The preparation concentration is the ammonium oxalate solution B of 0.5mol / L;

[0045] 4) Keep the aqueous solution A at a constant temperature of 70°C and stir at a constant speed at a speed of 400 rpm. At the same time, slowly add the ammonium oxalate solution B to the aqueous solution A. After the precipitation is completed, add 5-20% (excessive) ammonium oxalate solution B according to the stoichiometric ratio to ensure that the precipita...

Embodiment 2

[0054] 1. Preparation of LiNi by a new liquid phase method 0.5 mn 1.5 o 4 Cathode material

[0055] Change the total concentration of Ni and Mn ions in step 1) of Example 1 to 1 mol / L. Other conditions are identical with embodiment 1.

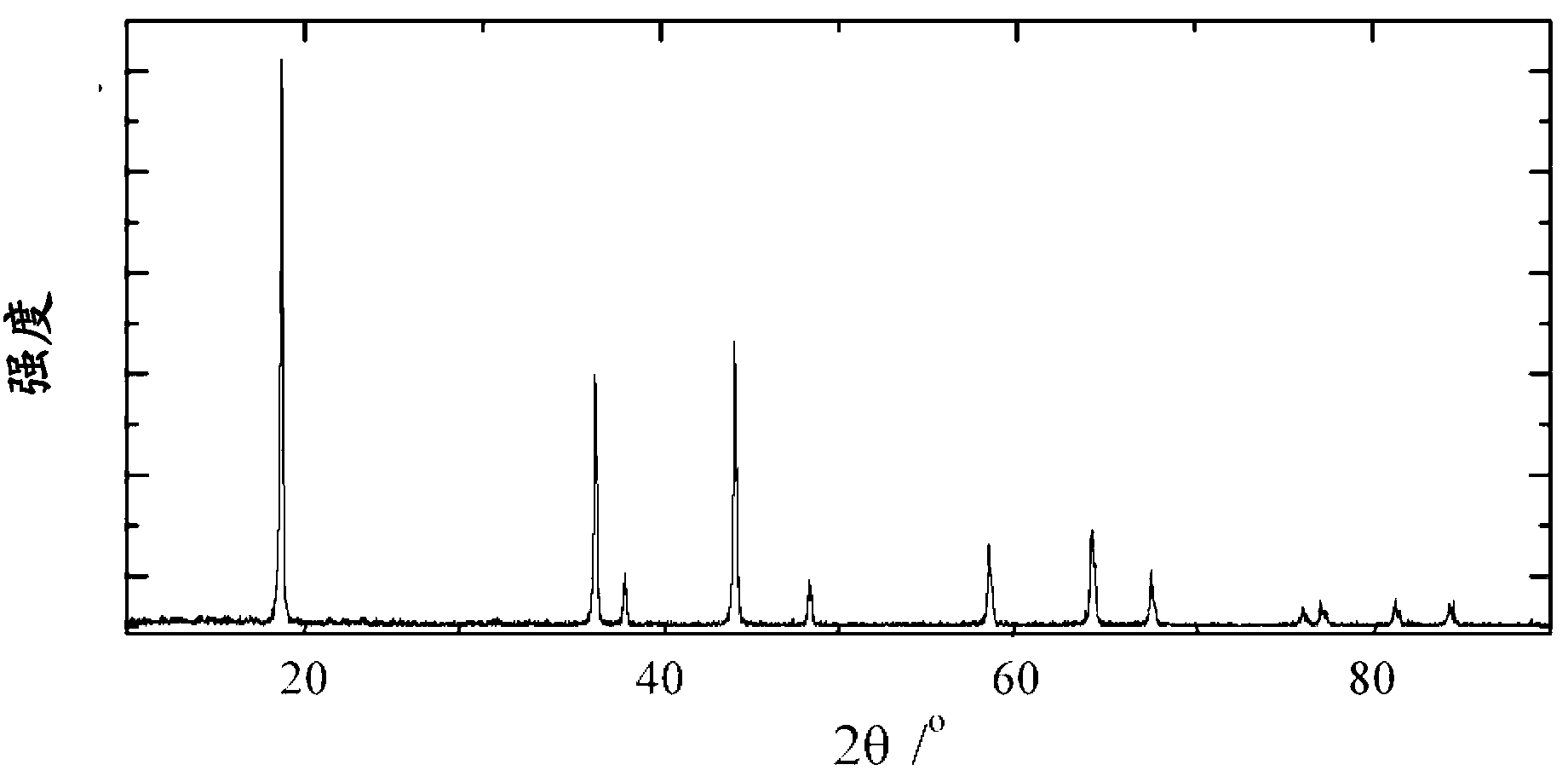

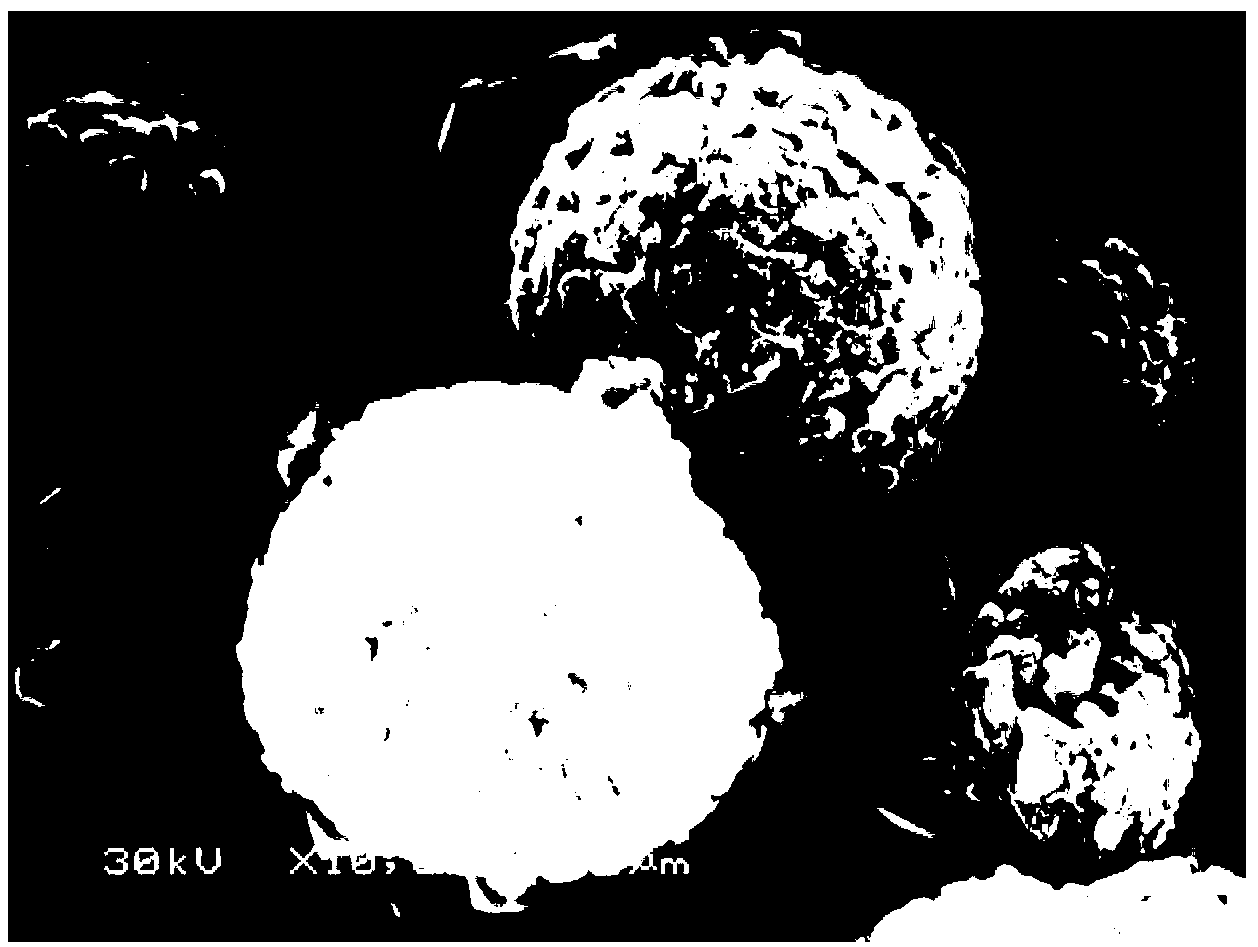

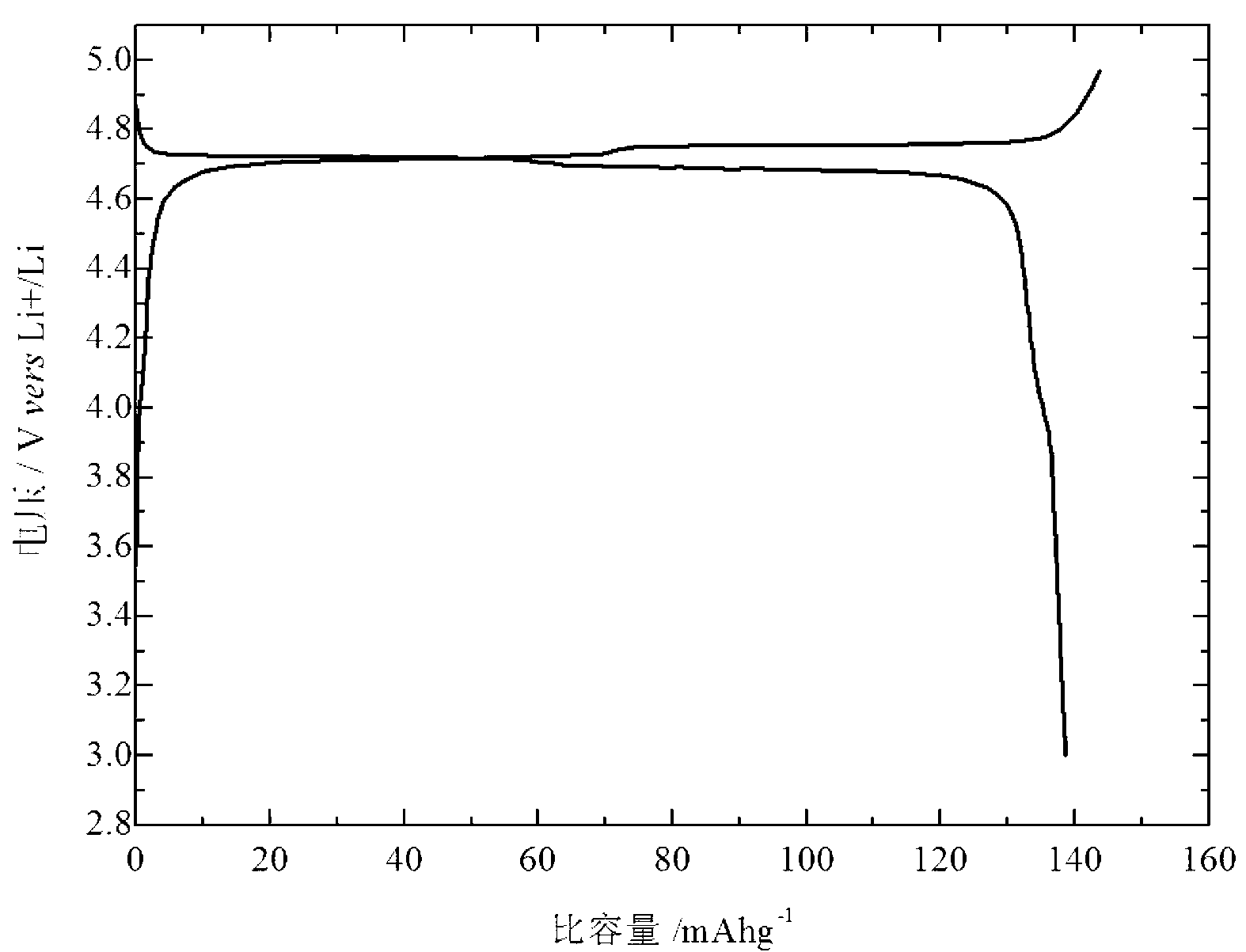

[0056] 2. LiNi prepared by this method 0.5 mn 1.5 o 4 The physical and electrochemical properties of

[0057] The detected LiNi 0.5 mn 1.5 o 4 The XRD characteristics of 1 are the same as those of 1, and SEM detection shows that the synthesized LiNi 0.5 mn 1.5 o 4 The particle size is about 3-4mm, and the tap density is 2.1 g / cm 3 . Using the same electrochemical test method, under the charge and discharge current of 0.3C, the material obtained in this example has an initial discharge specific capacity of 137.3 mAh / g, and the discharge capacity in the 4.7V high voltage region is 135.8 mAh hours / g, after 300 cycles, the capacity retention rate is 89%; under 3C conditions, the material has a discharge specific capacity of 121 mAh / g...

Embodiment 3

[0059] 1. Preparation of LiNi by a new liquid phase method 0.5 mn 1.5 o 4 Cathode material

[0060] Change the total concentration of Ni and Mn ions in step 1) of Example 1 to 0.1mol / L. Other conditions are identical with embodiment 1.

[0061] 2. LiNi prepared by this method 0.5 mn 1.5 o 4 The physical and electrochemical properties of

[0062] The detected LiNi 0.5 mn 1.5 o 4 The XRD characteristics of 1 are the same as those of 1, and SEM detection shows that the synthesized LiNi 0.5 mn 1.5 o 4 The particle size is about 10-15mm, and the tap density is 2.6 g / cm 3 . Using the same electrochemical test method, under the charge and discharge current of 0.3C, the material obtained in this embodiment has an initial discharge specific capacity of 130.3 mAh / g, and the discharge capacity in the 4.7V high voltage region is 126.8 mAh hours / g, after 300 cycles, the capacity retention rate is 91%; under 3C conditions, the material has a discharge specific capacity of 112...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com