Preparation method for electrolyte used for vanadium flow cell

A vanadium redox flow battery and electrolyte technology, which is applied in the direction of regenerative fuel cells, final product manufacturing, sustainable manufacturing/processing, etc. It can solve the problems of high sealing performance requirements of devices, low solubility of vanadium pentoxide, and difficulties in electrolysis , to achieve the effect of simple process, simple reaction equipment and less raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

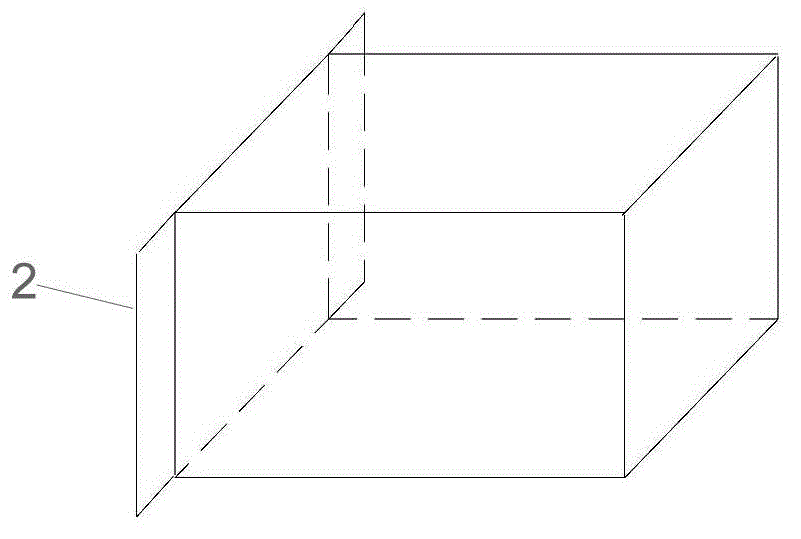

[0024] A method for preparing an electrolyte solution for a vanadium redox flow battery according to the present invention will be described in detail below with reference to the accompanying drawings and exemplary embodiments.

[0025] The vanadium redox flow battery electrolyte is divided into negative electrolyte and positive electrolyte. V in the negative electrolyte 2+ and V 3+ Coexistence, the concentration of total vanadium is 2.0mol / L, including 2~4mol / L free sulfuric acid; VO in positive electrolyte 2+ :VO 2 + Coexistence, the concentration of total vanadium is 2.0mol / L, including 2-4mol / L sulfuric acid. When the state of charge is zero, the composition of the positive and negative electrolytes of the vanadium electrolyte is the same, and the form of vanadium is V 3+ : VO 2+ = 1:1, and V 3+ with VO 2+ The total amount is 1.5~2mol / L.

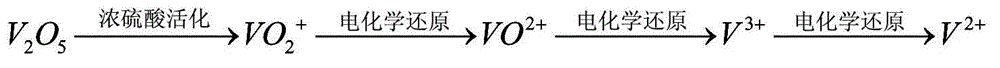

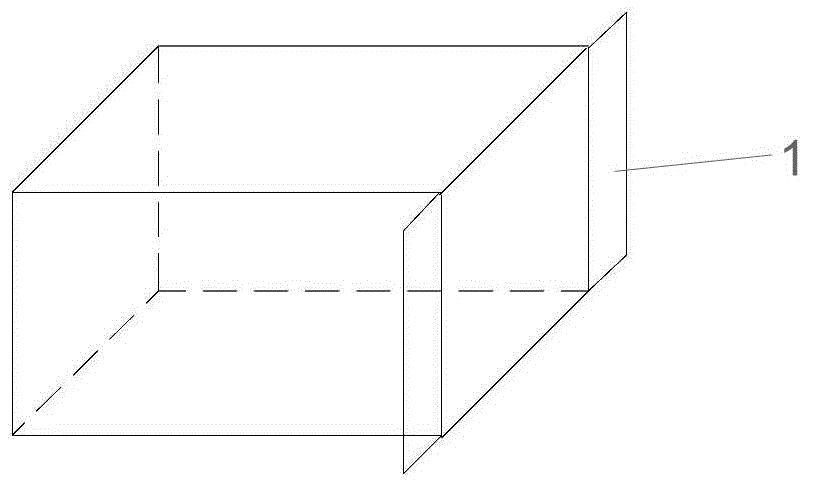

[0026] figure 1 It is a process flow chart of a method for preparing an electrolyte solution for a vanadium redox flow batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com