Natural product feed additive from bamboo

A feed additive and natural product technology, applied in animal feed, animal feed, application, etc., can solve problems such as food quality decline, immune function reduction, animal product safety concerns, etc., and achieve the effect of preventing oxidation and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1, a kind of feed additive derived from bamboo, carries out following steps successively:

[0080] 1) Take the dried green leaves of moso bamboo (moisture content ≤ 14%) collected in autumn and winter and crush them to about 10 meshes, add 500 L of pure water to each 50 kg and heat reflux to extract for 1.5 h, and vacuum concentrate the obtained filtrate after filtration (vacuum degree 0.09 Mpa, temperature ≤55 ℃) to a solid content of about 25% (mass %), spray drying (inlet air temperature 185 ℃, outlet air temperature 90 ℃), to obtain 4.1 kg of bamboo leaf extract (brown yellow powder, total phenol content 29.02%, polysaccharide content 8.21%).

[0081] 2) Take the by-products of boiled canned bamboo shoots processing - bamboo shoot shell and bamboo shoot head dry powder (about 30 mesh, moisture content ≤ 12%, the dry weight ratio of bamboo shoot shell and bamboo shoot head is 1:1.5), add 500 ml of pure water for every 50 kg L heat reflux extraction for 2 ...

Embodiment 2

[0090] According to the dry basis mass ratio, take 3 parts of dry green leaves (moisture content ≤ 14%), bamboo shoot shell and bamboo shoot head dry powder (moisture content ≤ 12%, and the dry weight ratio of bamboo shoot shell and bamboo shoot head is 1:1.5) Mix 2 parts with 1 part of bamboo shaving powder (moisture content ≤ 10%), add 500 L of 30% (v / v) ethanol-water solution per 50 kg, heat reflux extraction for 2 h, and vacuum concentrate the filtrate to the solid content At about 30%, after vacuum drying (vacuum degree 0.09 Mpa, temperature ≤ 65 ℃), 4.3 kg of the feed additive of the present invention (brown yellow powder, total phenol content 23.28%, polysaccharide content 12.13%, triterpene content 6.24% ). Record as recipe 6 # .

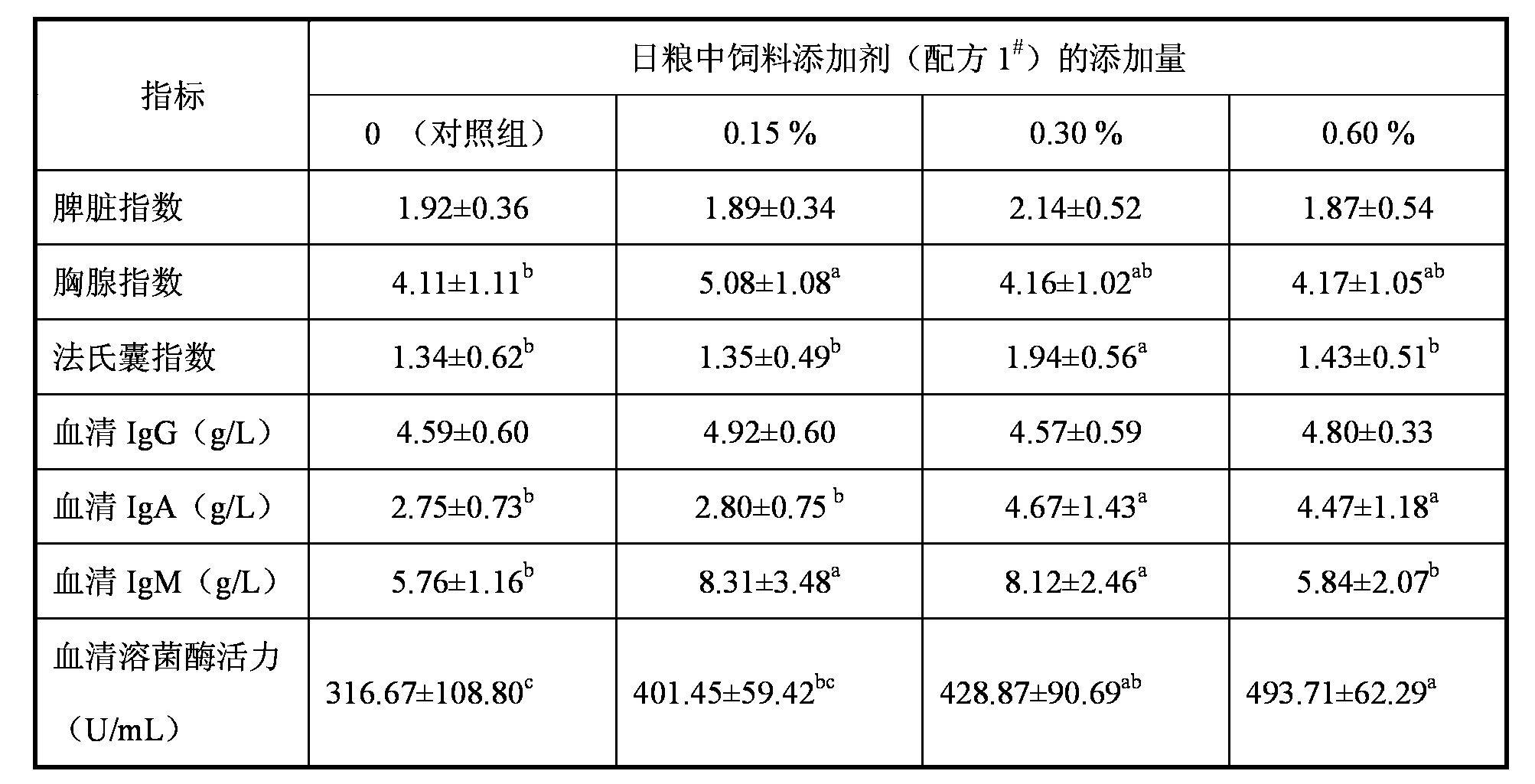

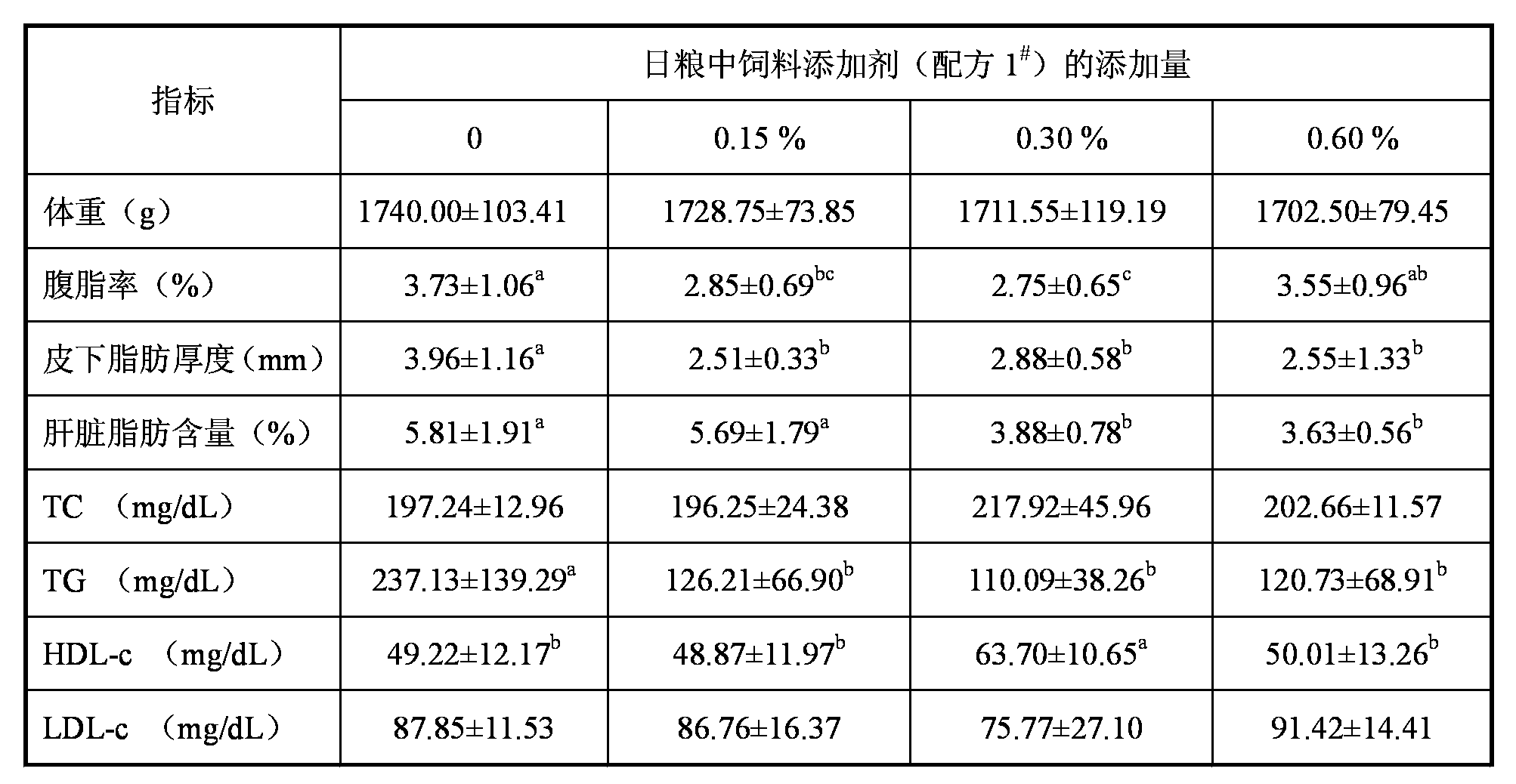

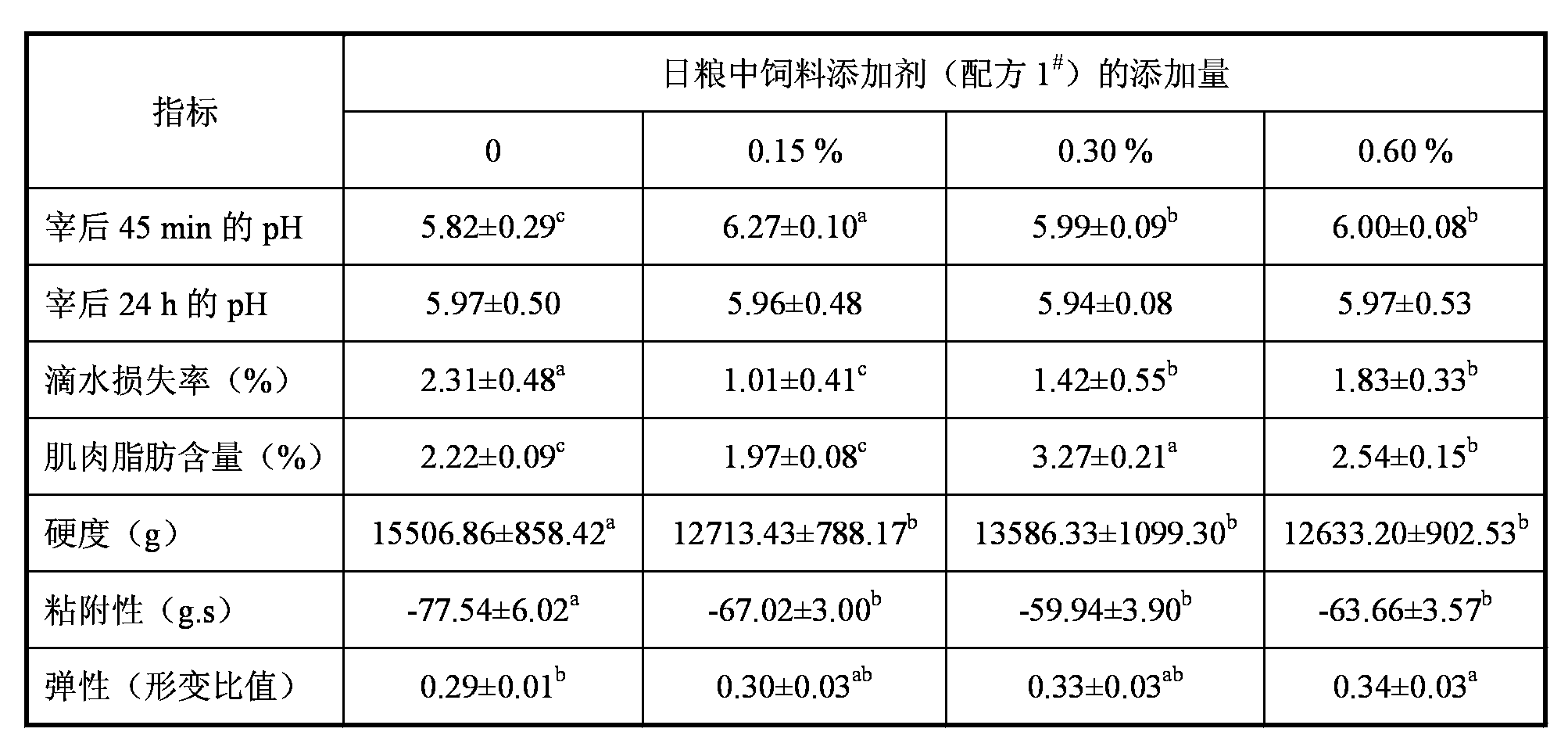

[0091] Experiment 1

[0092]The present invention will feed additive formula 1 in embodiment 1 # For high quality broiler farming.

[0093] 1. Experimental design

[0094] Shiqi bearded chicken (a yellow-feathered broiler chicken bred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com