Organic semiconductor material, and preparation method and application thereof

An organic semiconductor and organic palladium technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, organic chemistry, etc., can solve the problems of short lifespan and low luminous efficiency, and achieve high production efficiency, low cost, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

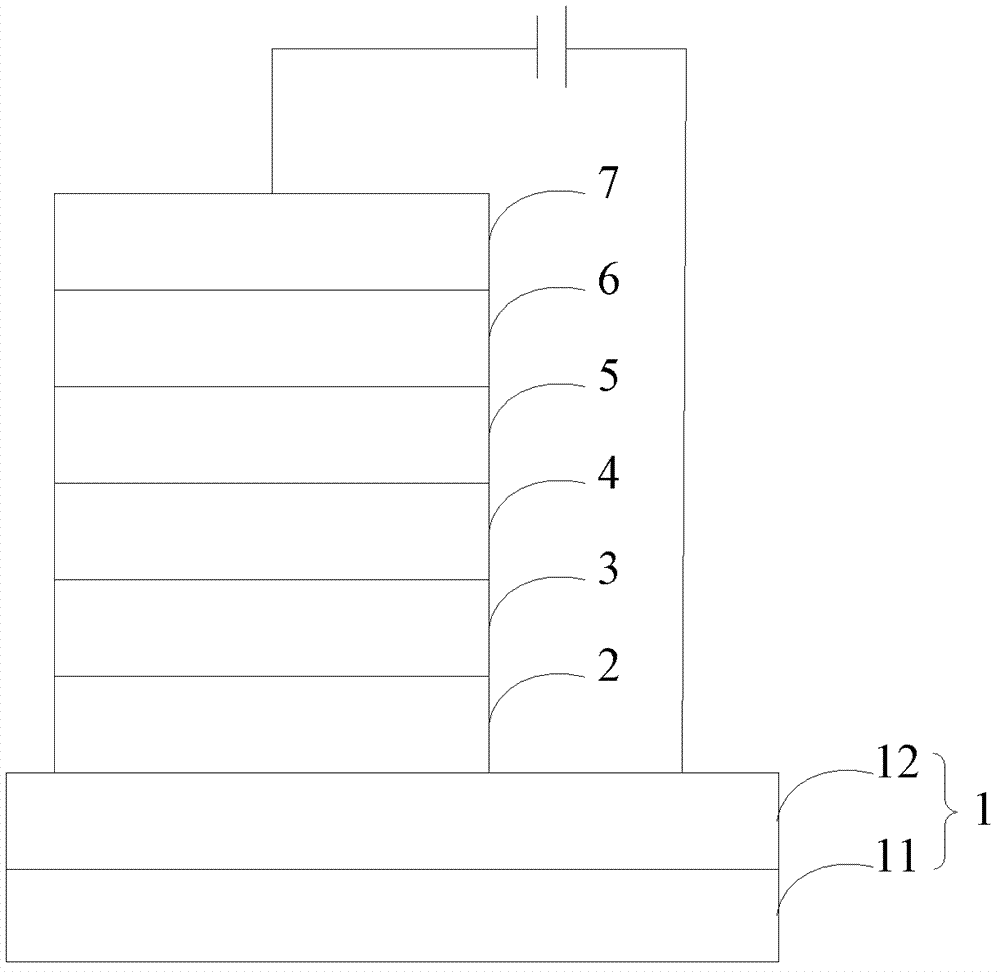

[0023] The embodiment of the present invention further provides a method for preparing the above-mentioned organic semiconductor material, including the following steps:

[0024] Step S01, providing raw materials:

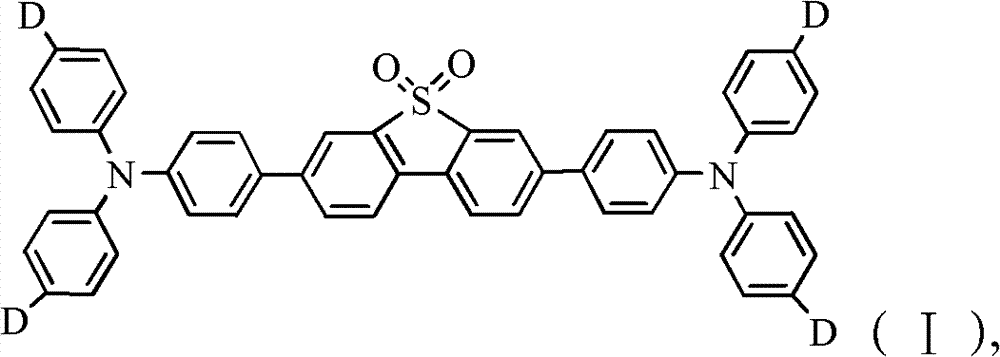

[0025] Provide the structural formula as Compound A, the structural formula is The compound B, wherein, D is selected from hydrogen atom (-H), alkyl (-R), alkoxyl (-OR);

[0026] Step S02, Suzuki reaction:

[0027] Compound A and Compound B with a molar ratio of 1:2 to 3 were dissolved in a catalyst and a basic organic solvent, and Suzuki reaction was carried out under anaerobic conditions and at a temperature of 60°C to 130°C for 20 hours to 40 hours to obtain the following: The organic semiconductor material of structural formula I, reaction formula is expressed as:

[0028]

[0029] Specifically, in step S01, compound A can be purchased from the market, or can be prepared by the following method:

[0030]

[0031] Dissolve dibenzothiophene sulfone i...

Embodiment 2

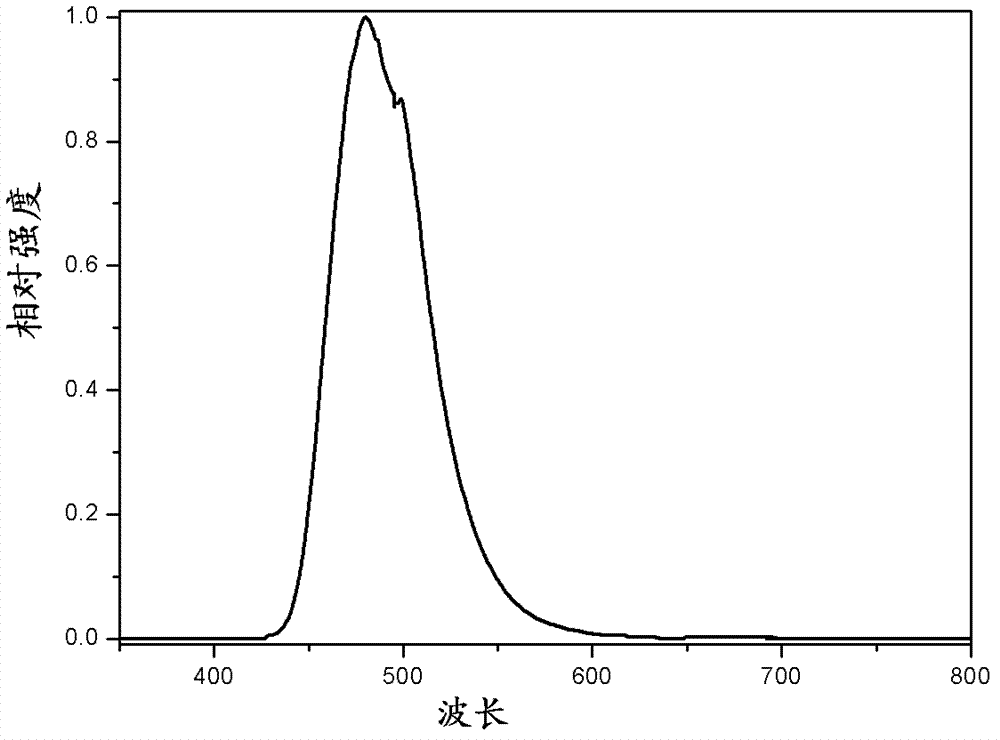

[0041] Example 2 of the present invention, 7-bis(4-(bis(4-tolyl)amine)phenyl)dibenzothiophene sulfone (DMPFSO) has the following structural formula:

[0042]

[0043] Example 2 of the present invention, the preparation method of 7-bis(4-(bis(4-tolyl)amine)phenyl)dibenzothiophene sulfone (DMPFSO) comprises the following steps:

[0044] Step 1, preparation of 2,7-dibromodibenzothiophene sulfone:

[0045] Dissolve 4 mmol of dibenzothiophene sulfone in 30 ml of concentrated H 2 SO 4Add 8.2mmol NBS at 20°C, stir the reaction for 24 hours, pour the reaction solution into water, filter it with suction, wash with water and methanol, and recrystallize the remaining solid in chlorobenzene to obtain a colorless needle-like solid 2 , 7-Dibromodibenzothiophene sulfone. Yield: 49%. MS: m / z 374 (M + ). The reaction formula is expressed as:

[0046]

[0047] Step 2, the preparation of 2,7-bis(4-(bis(4-tolyl)amine)phenyl)dibenzothiophene sulfone (DMPFSO):

[0048] Add 3mmol of 2,...

Embodiment 2

[0051] Example 2 of the present invention, 7-bis(4-(bis(4-hexylphenyl)amine)phenyl)dibenzothiophene sulfone (DHPFSO) has the following structural formula:

[0052]

[0053] Example 2 of the present invention, the preparation method of 7-bis(4-(bis(4-hexylphenyl)amine)phenyl)dibenzothiophene sulfone (DHPFSO) comprises the following steps:

[0054] Step 1, same as Step 1 in Embodiment 1

[0055] Step 2, the preparation of 2,7-bis(4-(bis(4-hexylphenyl)amine)phenyl)dibenzothiophene sulfone (DHPFSO):

[0056] 3mmol of 2,7-dibromodibenzothiophene sulfone, 6.8mmol of 4-(bis(4-hexylphenyl)amine) phenylboronic acid, and 0.3mmol of tetrakistriphenylphosphine palladium were added to the reactor, pumped After vacuum and nitrogen circulation for 3 times, make the reaction system under nitrogen protection, add 50mL of anhydrous tetrahydrofuran solution, 34ml of Na with a concentration of 2mol / L 2 CO 3 Aqueous solution, the temperature of the reaction system was adjusted to 60°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com