Graphene oxide-silver compound particle and preparation method thereof

A technology of composite particles and graphene, which is applied in the direction of graphene, microsphere preparation, microcapsule preparation, etc., can solve the problems of long reduction time, agglomeration, and affecting the performance of metallic silver, so as to reduce production costs, avoid agglomeration, and promote reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

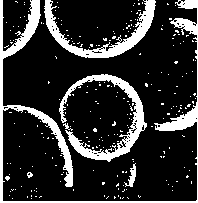

[0033] A graphene oxide and silver composite particle, which is a core-shell structure, the core is an organic particle, and the shell is a graphene oxide-silver nanoparticle, wherein the organic particle and the graphene oxide-silver nanoparticle are calculated by mass ratio, that is, the organic particle : Graphene Oxide: Silver Nanoparticles: 100:1:0.5;

[0034] The organic particles are polystyrene microspheres.

[0035] The preparation method of above-mentioned a kind of graphene oxide and silver composite particle specifically comprises the steps:

[0036] (1), the concentration is 1mg·mL -1 Preparation of graphite oxide aqueous solution

[0037] Weigh 50 mg of graphite oxide (A. Wojcik, P. V. Kamat, ACS Nano 4 (2010) 6697) prepared by the Hummers method into 20 mL of deionized water, ultrasonically disperse evenly, transfer to a 50 mL volumetric flask, constant volume, and each subsequent Sonicate for 1 hour before use;

[0038] (2) Preparation of suspension of org...

Embodiment 2

[0046] A graphene oxide and silver composite particle, which is a core-shell structure, the core is an organic particle, and the shell is a graphene oxide-silver nanoparticle, wherein the organic particle and the graphene oxide-silver nanoparticle are calculated by mass ratio, that is, the organic particle : graphene oxide: silver nanoparticles is 100:2:0.5;

[0047] The organic particles are polystyrene microspheres.

[0048] The preparation method of above-mentioned a kind of graphene oxide and silver composite particle specifically comprises the steps:

[0049] (1), the concentration is 1mg·mL -1 Preparation of graphite oxide aqueous solution

[0050] With embodiment 1;

[0051] (2) Preparation of suspension of organic particles

[0052] The suspension of organic particles used in this example is an aqueous solution of polystyrene microspheres with a concentration of 50 mg / mL, purchased directly from Zhejiang Henghui Chemical Co., Ltd.;

[0053] (3) Add 5 mL of polyst...

Embodiment 3

[0056] A graphene oxide and silver composite particle, which is a core-shell structure, the core is an organic particle, and the shell is a graphene oxide-silver nanoparticle, wherein the organic particle and the graphene oxide-silver nanoparticle are calculated by mass ratio, that is, the organic particle : graphene oxide: silver nanoparticles is 100:1.5:0.5;

[0057] The organic particles are polystyrene microspheres.

[0058] The preparation method of above-mentioned a kind of graphene oxide and silver composite particle specifically comprises the steps:

[0059] (1), the concentration is 1mg·mL -1 Preparation of graphite oxide aqueous solution

[0060] With embodiment 1;

[0061] (2) Preparation of suspension of organic particles

[0062] The suspension of organic particles used in this embodiment is a polystyrene microsphere aqueous solution with a concentration of 50 mg / mL, which is directly purchased from Zhejiang Henghui Chemical Co., Ltd.;

[0063] (3) Add 5mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com