Chemical vapor crosslinking method for polyborosilazane fiber

A polyborosilazane, gas-phase cross-linking technology, applied in the chemical characteristics of fibers, chemical post-treatment of synthetic polymer rayon filaments, textiles and papermaking, etc. problem, to achieve the effect of being suitable for large-scale production, reducing the reaction temperature, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

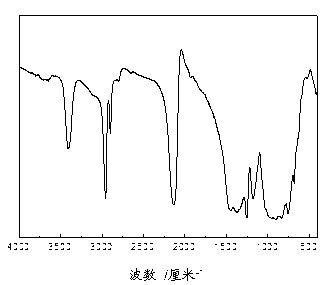

[0040] (1) The FT IR spectrum of PBSZ fibrils is as follows figure 1 shown. The main characteristic peaks in the figure belong to: 3429 cm -1 、3383 cm -1 、1179 cm -1 : N-H; 2955 cm -1 、2858 cm -1 : C-H; 2125 cm -1 : Si-H; 1472 cm -1 、1386 cm -1 : B-N; 913 cm -1 : Si-N; 1252 cm -1 : Si-C.

[0041] Put the PBSZ fibrils in the tube furnace of the existing chemical vapor phase cross-linking system, and evacuate to 6×10 -2 Pa, then replace the gas in the system with nitrogen to normal pressure, repeat three times; (2) vacuum to 6×10 -2 After Pa, inject diborane gas to normal pressure; (3) program temperature rise to 50°C, reaction time 24h; (4) program temperature rise to 400°C, hold time 2h, cool to room temperature, and serve.

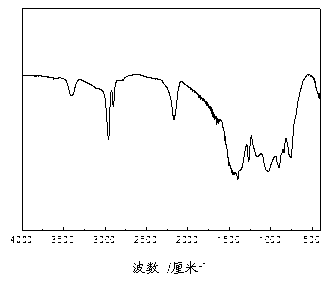

[0042] The FT IR spectrogram of gained crosslinked fiber is as figure 2 shown.

[0043] The obtained polyborosilazane crosslinked fiber gel content is 100%. Oxygen content analysis showed that the oxygen content of PBSZ fibrils was 0.84wt%...

Embodiment 2

[0047] Place the PBSZ fibrils in the existing chemical vapor phase cross-linking system equipment, vacuumize and replace the gas in the system with high-purity nitrogen or high-purity argon to normal pressure, repeat three times; Gas to normal pressure; (3) Program temperature rise to 80°C, reaction time 12h; (4) Program temperature rise to 350°C, holding time 6h, cool to room temperature, ready to serve.

[0048] The FT IR spectrogram of gained PBSZ cross-linked fiber and figure 2 Basically the same, only the intensity of the absorption peak is slightly different.

Embodiment 3

[0050] Put the PBSZ fibrils in the existing chemical vapor phase cross-linking system equipment, vacuumize and replace the gas in the system with high-purity nitrogen or high-purity argon to normal pressure, repeat three times; Pentaborane to normal pressure; (3) Program temperature rise to 100°C, reaction time 8h; (4) Program temperature rise to 400°C, holding time 2h. Let cool to room temperature and serve.

[0051] FT IR spectra of PBSZ cross-linked fibers and figure 2 Basically the same, only the intensity of the absorption peak is slightly different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com