Tricholoma matsutake dried product with nutrients and flavor fully preserved, and preparation method thereof

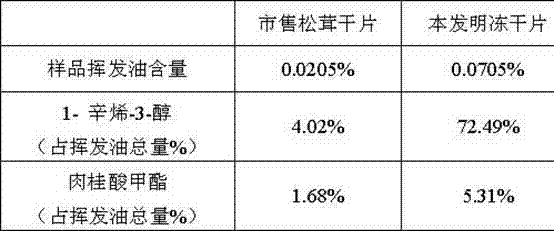

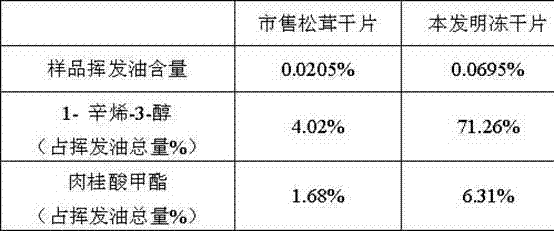

A technology of nutritional components and dry products, which is applied in food preparation, application, food science, etc., can solve the problems of large loss of volatile components, short storage time, short storage time, etc., to reduce decomposition and oxidation, and reduce loss of nutritional components , the effect of prolonging the preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

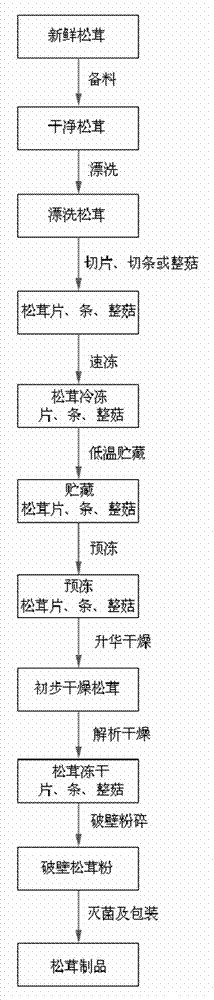

Method used

Image

Examples

Embodiment 1

[0039] Take the wild fresh matsutake produced in Shangri-La, Yunnan, remove the soil, weeds, mildew and broken matsutake, wash it with clean water, then quickly air-dry the surface at room temperature, and cut it into 5mm thin slices longitudinally; spread the matsutake thin slices on a 30mm thick plate in the freezer And put it in the quick-freezing device, and complete the quick-freezing at -22°C for 1 hour; quickly put the quick-frozen matsutake slices into a vacuum freeze-drying device with a pressure of 80Pa according to the thickness of 40mm, and sublimate and dry at -25°C for 8 hours; The central temperature of the matsutake was 40°C, and the pressure was 70Pa, which was analyzed and dried for 5 hours, and then the freeze-dried sheets of matsutake with a moisture content of 3% were obtained.

Embodiment 2

[0041] Take wild fresh matsutake produced in Shangri-La, Yunnan, remove soil, weeds, mildew and broken matsutake, wash with water, rinse in 0.5% citric acid solution for 10 minutes, then filter and dry the excess water on the surface, cut into 3mm lengthwise Thin slices of matsutake; spread the matsutake thin slices in a staggered manner according to the thickness of 50mm and place them in the quick-freezing device, and heat them at -35°C for 1.5h to complete the quick-freezing; quickly put the quick-frozen matsutake into a vacuum with a pressure of 40Pa according to the thickness of 10mm In the freeze-drying device, heat preservation and sublimation drying at -19°C for 5 hours; then analyze and dry the matsutake at a central temperature of 25°C and a pressure of 40Pa for 3 hours, and obtain freeze-dried matsutake slices with a moisture content of 5%; the discharged materials are finely crushed into 100 mesh matsutake broken walls powder, and then 400 krad gamma-ray irradiation...

Embodiment 3

[0043]Take wild fresh matsutake produced in Lijiang, Yunnan, remove soil, weeds, mildew and broken matsutake, wash with water, rinse in 1% citric acid solution for 5 minutes, use a dehydrator to remove excess water on the surface, cut longitudinally into thin slices of 7 mm; spread the matsutake slices on a freezing plate with a thickness of 20 mm and place them in a quick-freezing device, and heat them at -45 ° C for 0.5 h to complete the quick-freezing; store the quick-frozen matsutake slices at 0 ° C; The stored matsutake slices were laid flat in a freezer tray with a thickness of 20mm and pre-frozen at -30°C, and then the pre-frozen matsutake slices were placed in a vacuum freeze-drying device with a pressure of 60Pa, and sublimated and dried at -30°C for 12 hours; then The central temperature of matsutake is 35°C, the pressure is 50P, and it is analyzed and dried for 11 hours, and the material is discharged to obtain freeze-dried matsutake slices with a moisture content of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com