Preparation method of proton exchange membrane fuel cell catalyst

A proton exchange membrane and fuel cell technology, applied in solid electrolyte fuel cells, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low electrochemical performance, difficulty in preparing catalysts, and reduced particle size uniformity of metal particle catalysts and other problems to achieve the effect of uniform particle size and high electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of a proton exchange membrane fuel cell catalyst, which comprises the following steps:

[0035] A) Mix the precious metal halide solution and carbon black, adjust the pH to 2.5~10.5, and perform ultrasonic stirring to obtain the precursor fluid;

[0036] The precious metal halide is a platinum halide or a mixture of platinum halide and ruthenium halide;

[0037] B) Add the precursor liquid to the sodium borohydride solution, and perform ultrasonic stirring to obtain a mixed liquid;

[0038] C) The mixed solution is allowed to stand still, filtered, washed and dried to obtain a proton exchange membrane fuel cell catalyst.

[0039] The present invention first adds carbon black to the precious metal halide solution to mix, adjusts the pH value of the solution and performs ultrasonic stirring to obtain a precursor fluid. The noble metal halide is a platinum halide or a mixture of platinum halide and ruthenium halide, wherein the platinum h...

Embodiment 1

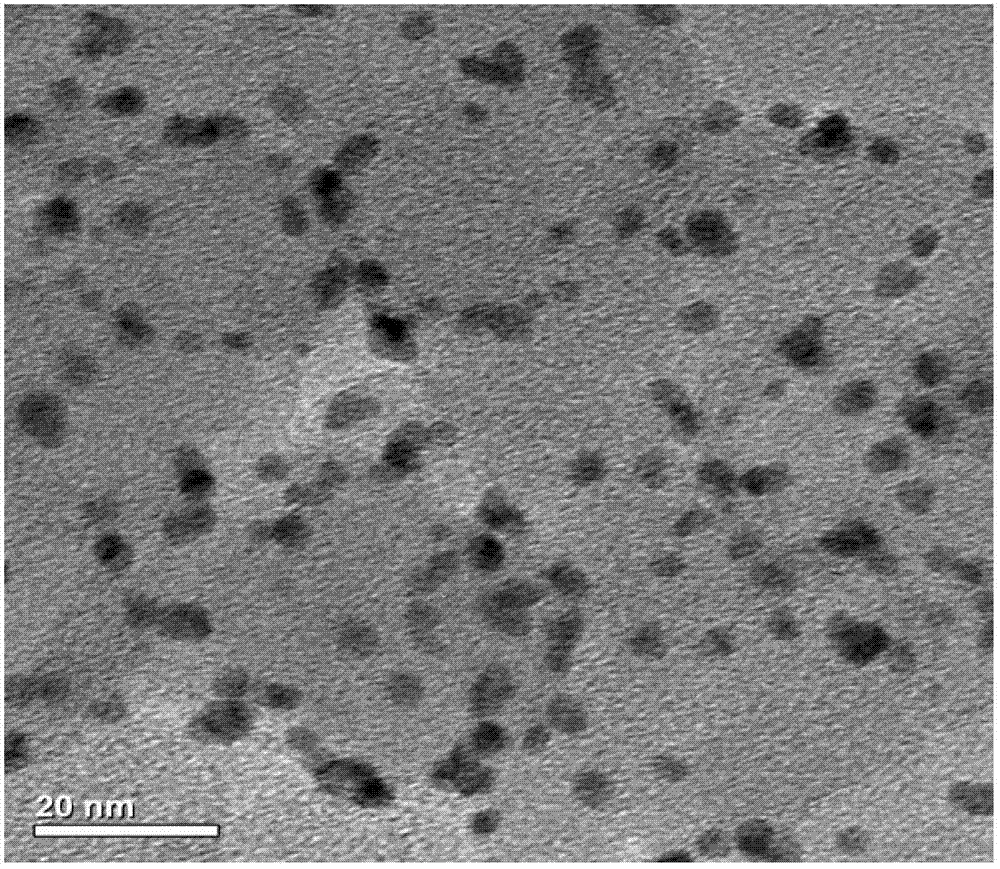

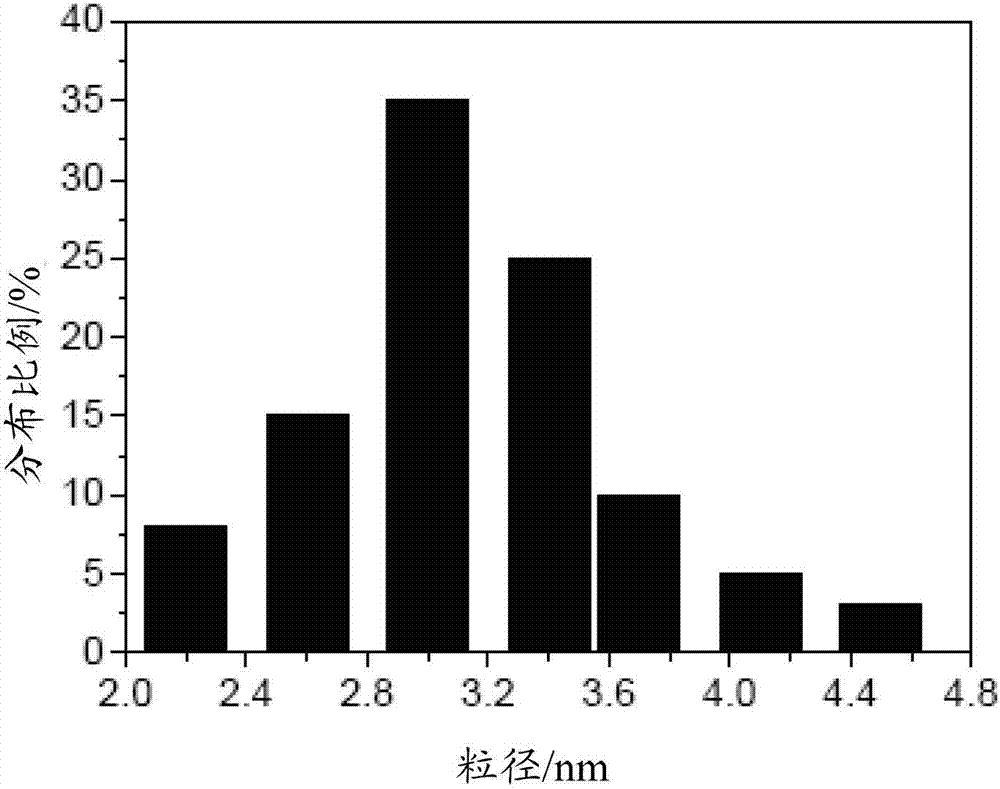

[0050] Dissolve chloroplatinic acid in deionized water to prepare a 1L aqueous solution, in which the platinum ion content in the solution is 5g / L. Add carbon black to the chloroplatinic acid solution for adsorption, so that the loading of chloroplatinic acid on the carbon black is 20wt %, ultrasonic agitation to obtain a suspension, heat the suspension to 50° C., hold for 1 hour, adjust the pH of the suspension to 7.5 with an aqueous ammonia solution, and stir the suspension under ultrasonic conditions for 30 minutes to obtain a precursor fluid.

[0051] Take 1 g of sodium borohydride and add it to 10 mL of deionized water to prepare a sodium borohydride solution.

[0052] The precursor fluid is quickly poured into the sodium borohydride solution, while ultrasonic stirring is performed, and the mixture is maintained for 1 hour to obtain a mixed solution.

[0053] The mixed solution is allowed to stand for 1 hour and filtered to obtain a solid substance, which is washed with deionize...

Embodiment 2

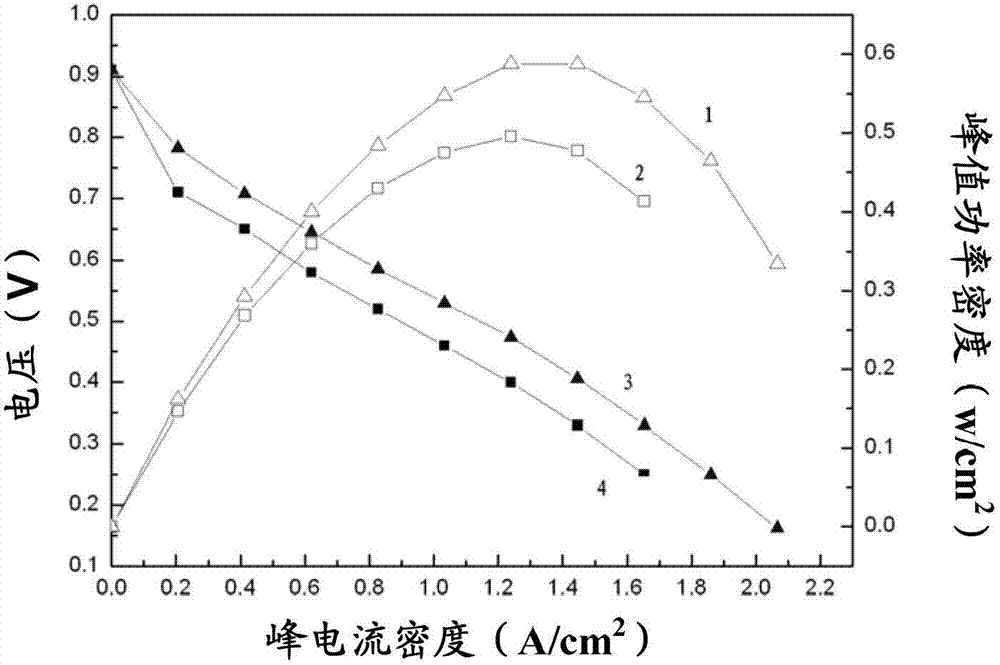

[0063] Dissolve chloroplatinic acid / chlororuthenic acid in deionized water to prepare a 1L aqueous solution, in which the content of platinum ion and ruthenium ion in the solution is 5g / L, and the molar ratio of platinum to ruthenium is 1:0.5. Add carbon black to the chlororuthenic acid solution for adsorption so that the loading of chloroplatinic acid / chlororuthenic acid on the carbon black is 60wt%. Stir ultrasonically to obtain a suspension. Heat the suspension to 50°C and keep it for 1 hour. The pH value of the suspension was adjusted to 7.5 by the aqueous ammonia solution, and the suspension was stirred under ultrasonic conditions for 30 minutes to obtain a precursor fluid.

[0064] Take 5 g of sodium borohydride and add 10 mL of deionized water to prepare a sodium borohydride solution.

[0065] The precursor fluid is quickly poured into the sodium borohydride solution, while ultrasonic stirring is performed, and the mixture is maintained for 1 hour to obtain a mixed solution....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com