Treatment method of copper chloride hydroxide production wastewater

A technology of production wastewater and treatment method, which is applied to the treatment of nitrogen elements, and can solve the problems of lack of cuprous ion recovery treatment, low ammonia nitrogen treatment efficiency, waste of resources and other problems in the field of copper in basic cupric chloride production wastewater, Achieve good application prospects, improve resource recycling efficiency, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the present invention will be described in detail in combination with specific embodiments.

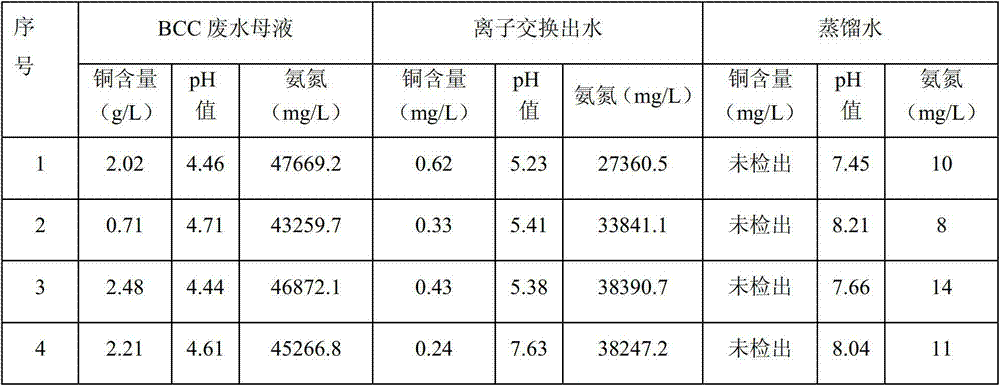

[0017] The main components of basic copper chloride (BCC) production wastewater are ammonium chloride and a certain amount of copper ions (Cu 2+ ), cuprous ion (Cu + ), ammonium sulfate, sodium chloride, the difficulty of wastewater treatment is mainly reflected in the removal of ammonia nitrogen and the recovery of copper ions.

[0018] The treatment method for basic copper chloride production wastewater provided by the present invention can improve the recovery efficiency of copper ions in various valence states, and further enable copper resources to be recycled; it also greatly improves the treatment efficiency of ammonia nitrogen and produces highly efficient economic benefits.

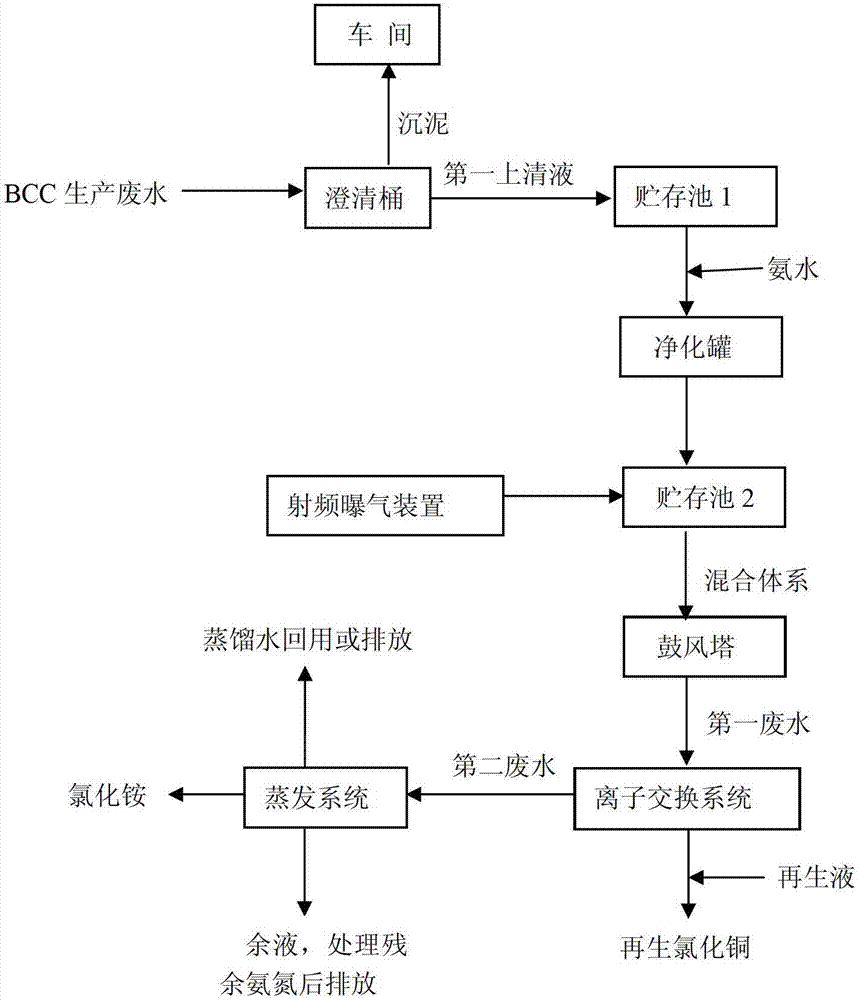

[0019] like figure 1 Shown, this processing method for basic cupric chloride production waste water, comprises the steps:

[0020] Step I: The BCC production wastewater is subjected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com