Melon/vegetable seedling raising organic compound substrate prepared from vinasse and production method thereof

A technology of composite substrate and distiller's grains, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, etc., can solve the problems of difficult treatment of inorganic substrates, limited peat resources, uneven distribution, etc., and achieves strong water retention and rich sources. , the effect of good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

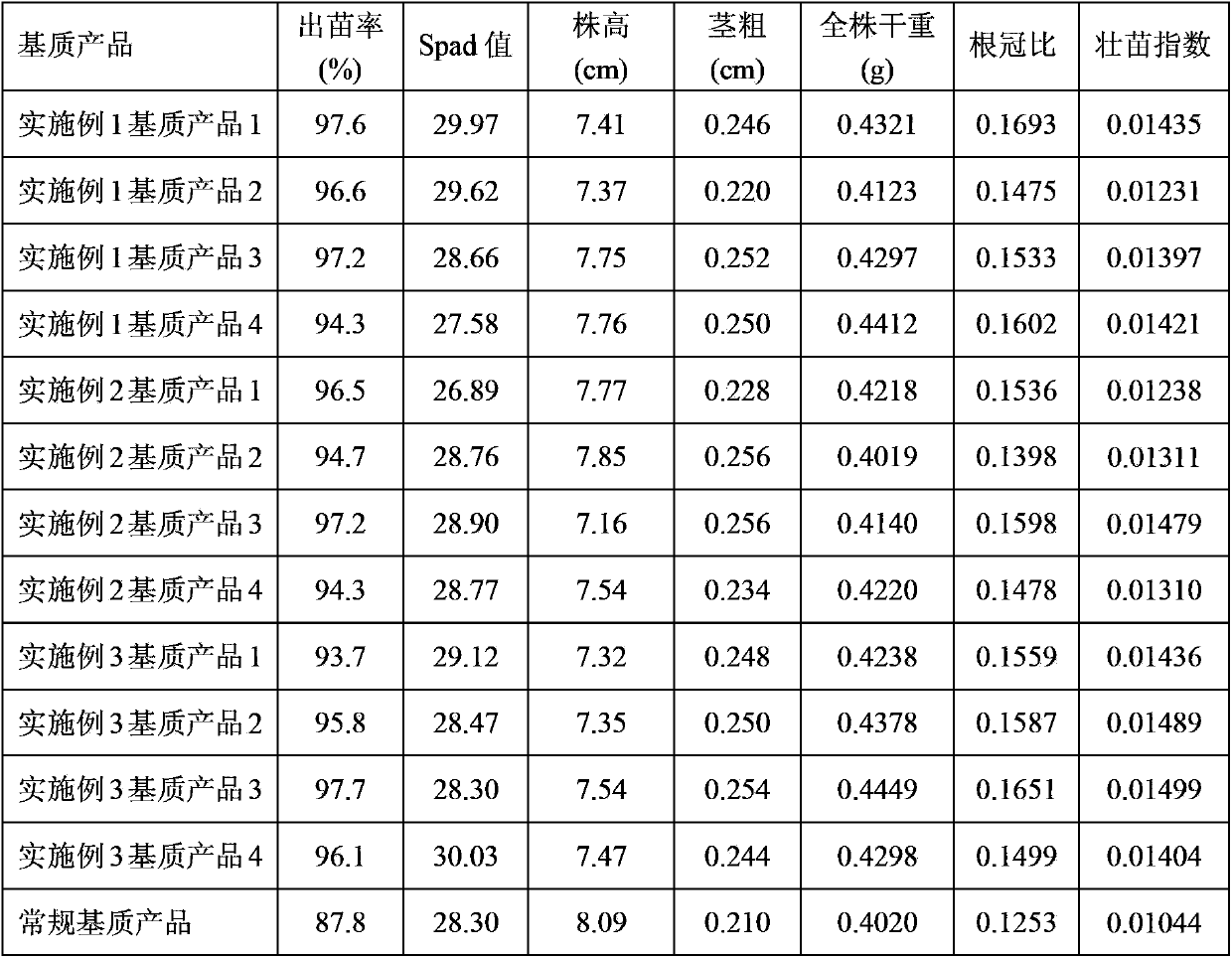

Examples

Embodiment 1

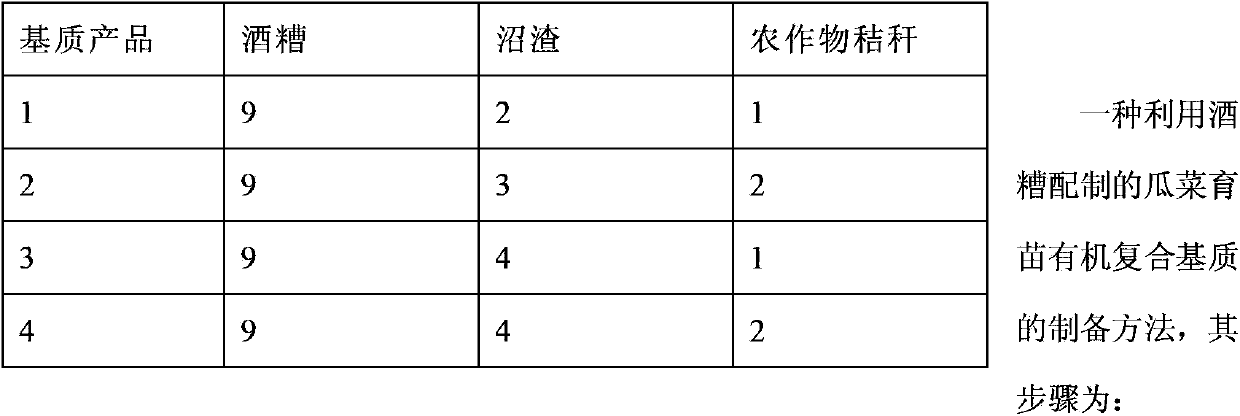

[0038] An organic composite substrate for growing melon and vegetable seedlings prepared from distiller's grains. After the components are decomposed, they are mixed according to the following volume ratio:

[0039] Matrix products

distiller's grains

Mushroom residue

1

2

1

2

2

3

3

4

1

4

4

3

[0040] A method for preparing an organic composite substrate for growing melon and vegetable seedlings prepared from distiller's grains, the steps of which are as follows:

[0041]Collect the distiller's grains and mushroom dregs, and crush the distiller's grains and mushroom dregs respectively so that the particle size does not exceed 1cm. The distiller's grains pile and the mushroom residue pile are pretreated as follows: fully rinse the crushed mushroom residue with tap water; add urea to adjust the C / N ratio of the pile to 30:1, increase or decrease the dry and wet materials to adjust the water content...

Embodiment 2

[0044] An organic composite substrate for growing melon and vegetable seedlings prepared from distiller's grains. After the components are decomposed, they are mixed according to the following volume ratio:

[0045] Matrix products

distiller's grains

1

1

1

2

1

2

3

3

1

4

3

2

[0046] A method for preparing an organic composite substrate for growing melon and vegetable seedlings prepared from distiller's grains, the steps of which are as follows:

[0047] Collect the distiller's grains and cow dung, and crush the distiller's grains and cow dung separately so that the particle size does not exceed 1cm. The distiller's grains and cow dung are pretreated as follows: add urea to adjust the C / N ratio to 30:1, increase or decrease dry and wet materials to adjust the water content to 60%, add quicklime to adjust the pH value to 8.0, and the quality of the starter The fraction is 0.3%. Then th...

Embodiment 3

[0050] An organic composite substrate for growing melon and vegetable seedlings prepared from distiller's grains. After the components are decomposed, they are mixed according to the following volume ratio:

[0051]

[0052] Collect distiller's grains, biogas residues, and crop straws, and crush the distiller's grains, biogas residues, and crop straws so that the particle size or length does not exceed 1 cm. The distiller's grains, biogas residues and crop straws are pretreated as follows: add urea to adjust the C / N ratio to 30:1, increase or decrease dry and wet materials to adjust the water content to 60%, add quicklime to adjust the pH value 8.0, the dosage of starter is 0.3%. Then the distiller's grains, biogas residues, and crop straws are piled into piles with a bottom width of 2m and a height of 1.5m. 2cm of straw and covered with a layer of plastic film. When the temperature exceeds 65°C for the first time, turn the pile once; during the high temperature period of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com