Fully-degradable heat-insulation mulch and preparation method thereof

A fully degradable, mulching technology, applied in the direction of plant protection cover, can solve the problems of yield impact, no insulation effect, affecting crop growth and development, etc., to increase the interface bonding force, improve mechanical compatibility and mechanical Performance, effect of reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

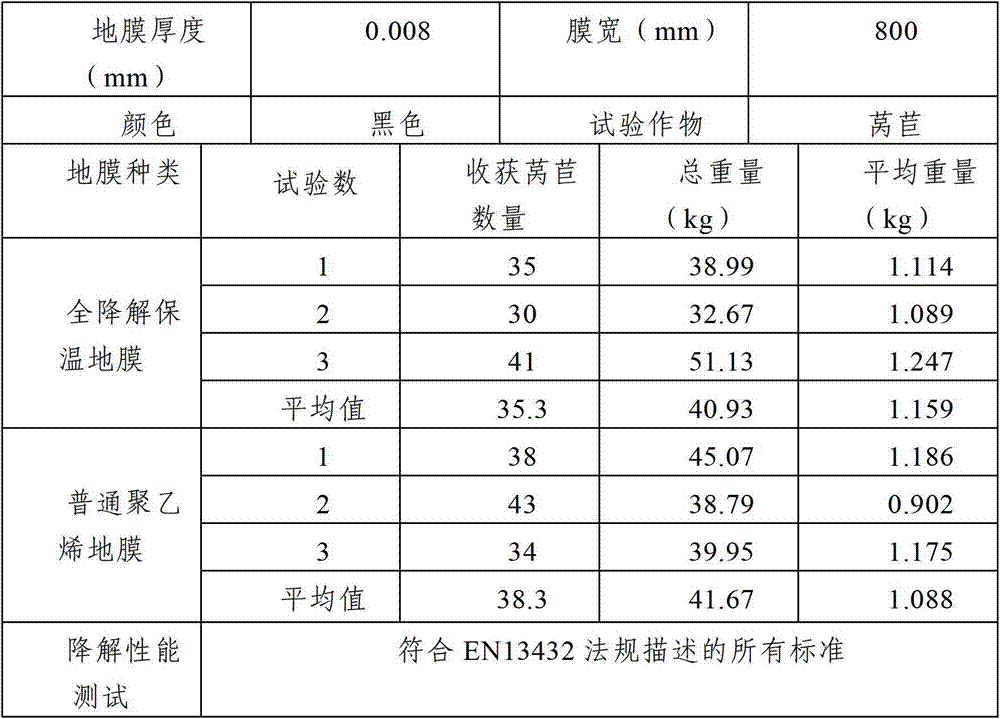

Embodiment 1

[0038] 60 parts by mass of hydrotalcite powder and 40 parts by mass of PBAT resin were uniformly mixed in a high-speed mixer, and extruded and granulated by a twin-screw extruder to obtain fully degraded hydrotalcite masterbatches.

[0039] 40 parts by mass of PBAT, 20 parts by mass of polylactic acid, 20 parts by mass of corn starch, 5 parts by mass of glycerin, 2 parts by mass of BASF chain extender JONCRYL ADR-4368, 5 parts by mass of fully degraded hydrotalcite masterbatch and 8 parts by mass of Light calcium carbonate is mixed evenly in a high-speed mixer, and then the mixture is mixed in a twin-screw extruder. The temperature of each section of the twin-screw extruder is set at T1=140°C, T2=150°C, and T3=150°C , T4=155°C, T5=155°C, T6=155°C, the speed of the twin-screw extruder is R=300r·min-1; after that, extrude, cool, and granulate to obtain the material for fully degradable thermal insulation film ;Combined with fully degradable color masterbatch after secondary proc...

Embodiment 2

[0043] 70 parts by mass of hydrotalcite powder and 30 parts by mass of PBAT resin were uniformly mixed in a high-speed mixer, and extruded and granulated by a twin-screw extruder to obtain fully degraded hydrotalcite masterbatches.

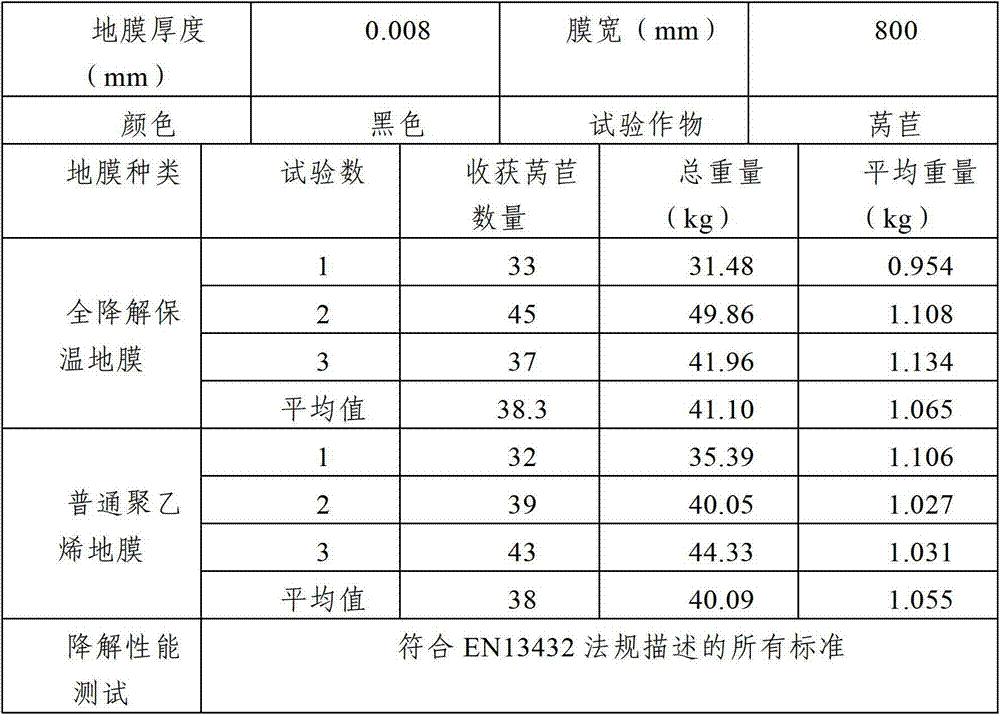

[0044] Mix 30 parts by mass of PBAT, 30 parts by mass of polylactic acid, 10 parts by mass of tapioca starch, 5 parts by mass of ethylene glycol, 20 parts of fully degraded hydrotalcite masterbatch and 5 parts by mass of talcum powder in a high-speed mixer, and then mix the mixture in Mixing in the twin-screw extruder, the temperature of each section of the twin-screw extruder is set as T1=155°C, T2=160°C, T3=165°C, T4=165°C, T5=160°C, T6=165°C, The speed of the twin-screw extruder is R=300r·min-1; after that, extrude, cool, and granulate to obtain the material for the fully degradable thermal insulation film; and then cooperate with the color masterbatch to obtain the fully degradable thermal insulation film through secondary processing , through...

Embodiment 3

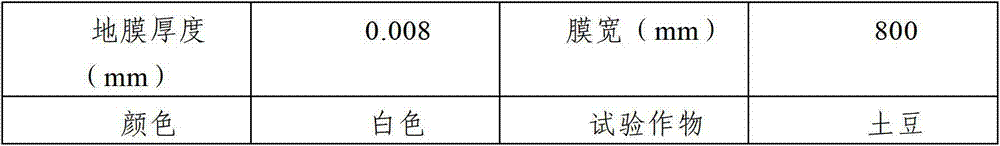

[0048] 50 parts by mass of hydrotalcite powder and 50 parts by mass of PBAT resin were uniformly mixed in a high-speed mixer, and extruded and granulated by a twin-screw extruder to obtain fully degradable hydrotalcite masterbatches.

[0049] Mix 60 parts by mass of poly PBAT, 10 parts by mass of polylactic acid, 10 parts by mass of corn starch, 5 parts by mass of propylene glycol, 10 parts by mass of fully degraded hydrotalcite masterbatch and 5 parts by mass of light calcium carbonate in a high-speed mixer, and then The mixture is kneaded in the twin-screw extruder, and the temperature of each section of the twin-screw extruder is set as T1=145°C, T2=155°C, T3=160°C, T4=160°C, T5=165°C, T6= 165°C, the speed of the twin-screw extruder is R=300r·min-1; after that, extrude, cool, and granulate to obtain the material for the fully degradable thermal insulation film; and then cooperate with the fully degradable color masterbatch to undergo secondary processing. Obtain fully degra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com