Fire retardant foaming material for halogen-free flame retardant cable and preparation method of fire retardant foaming material

A technology of flame-retardant cables and foaming materials, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of cost increase, scattering, loss of fire protection and protection functions, etc., and achieve the effect of increasing the temperature gradient and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

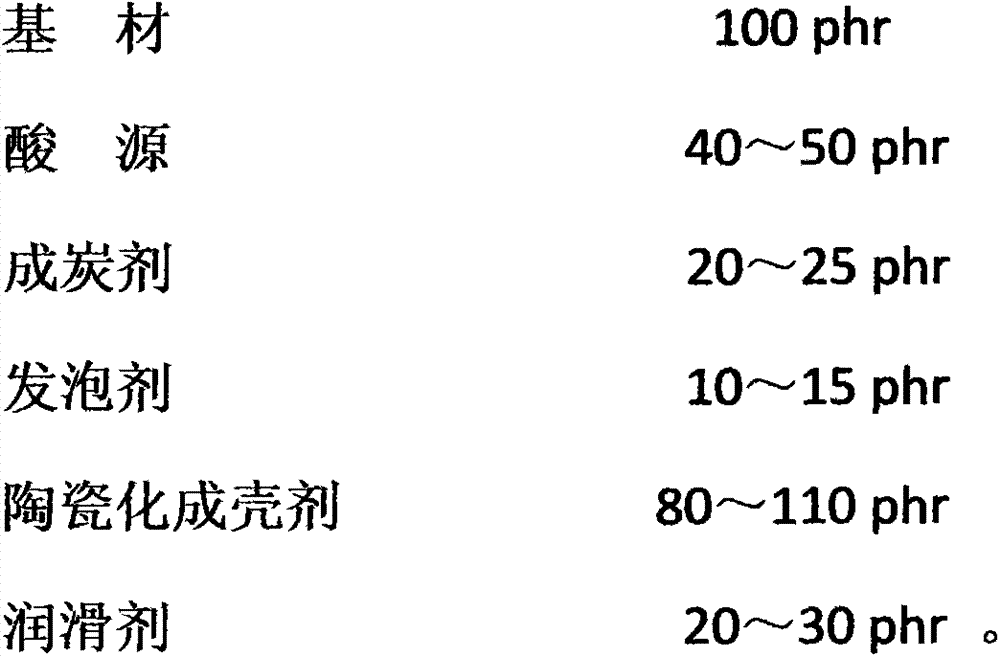

Method used

Image

Examples

Embodiment Construction

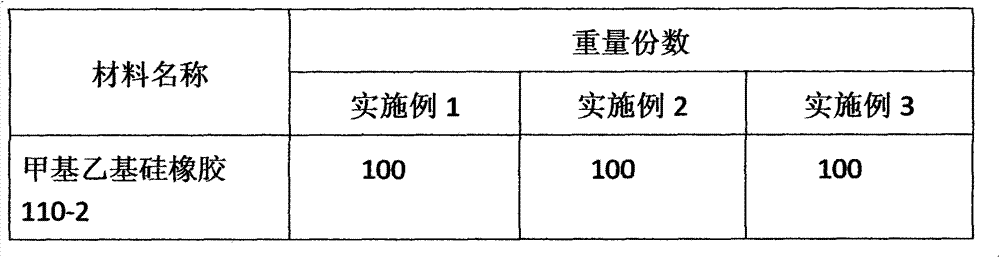

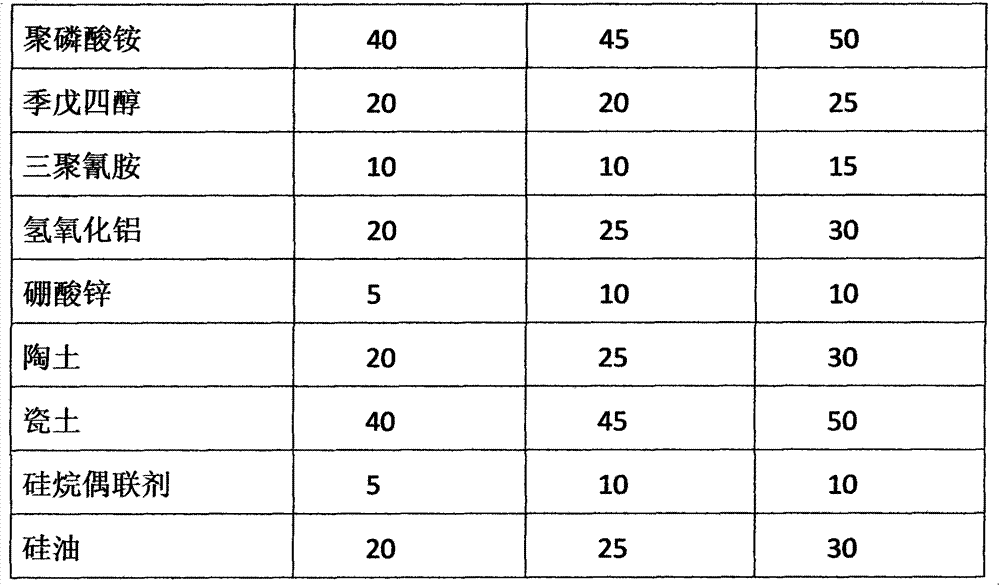

[0017] The present invention uses methyl ethyl silicone rubber 110-2 as the base material, which can be highly filled, has good process performance, and fully meets the performance requirements of flexible cables and the like.

[0018] A fire-retardant foaming material for a halogen-free flame-retardant cable according to the present invention and its preparation method are as follows: mix ingredients according to the weight of the formula, first put the silica gel into the banbury mixer, and then put into ammonium polyphosphate, foaming agent and synthetic For charcoal, add ceramic shell-forming agent after banburying for 2-3 minutes, then add lubricant and coupling agent, and unload after banburying for 2 minutes. Thinly pass the rubber material after banburying on the mill for three times at 18 o'clock, then make five triangular bags, and then pass it twice, then roll the next sheet or strip; or directly mix by the normal temperature double-roller open mill After 5-10 minut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap