Weather-proof terrace paint as well as preparation method thereof

A floor coating and weather-resistant technology, applied in the field of coatings, can solve the problems such as weather resistance, aging resistance, poor wear resistance, and poor hardness of floor coatings that are not mentioned, achieve a highly controllable reaction rate, and avoid polymerization. Incomplete, the effect of improving technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

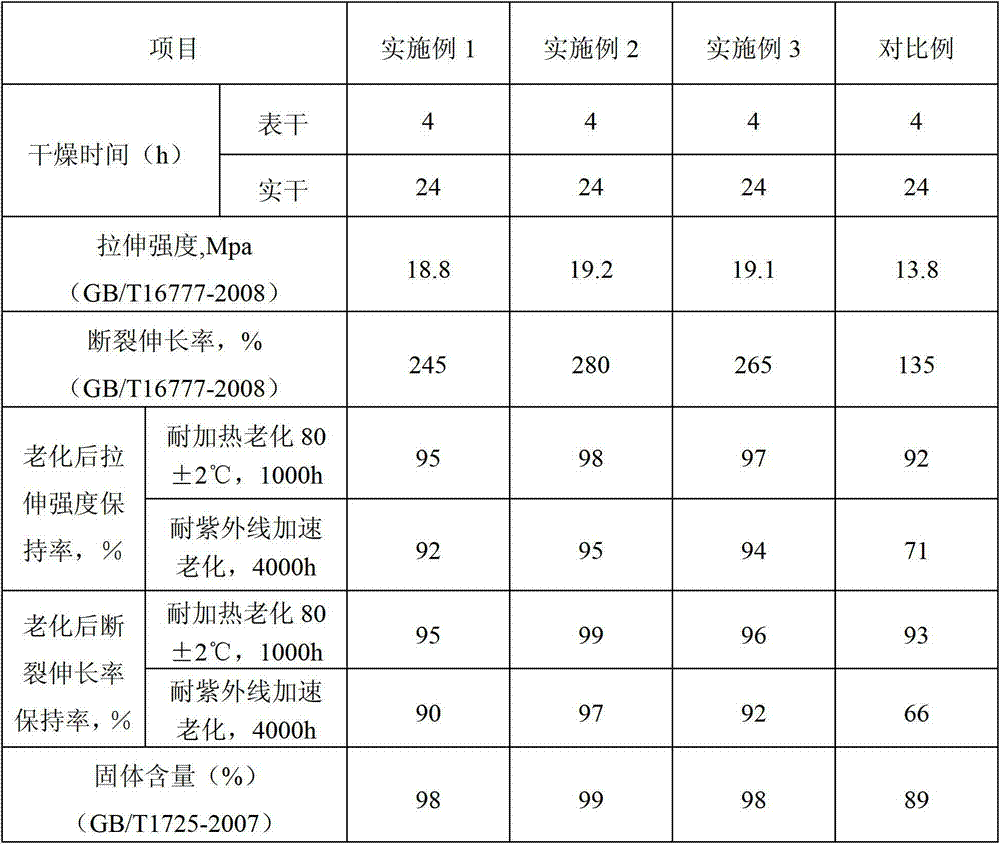

Examples

preparation example Construction

[0094] Various high-speed mixers are required in the preparation process of the paint, and spraying, flow coating and other methods are used for painting. In these processes, the paint will generate foam. The air in the foam will not only hinder the dispersion of pigments and fillers, but also make the utilization rate of the equipment insufficient and affect the output. The air bubbles generated during construction will cause surface defects of the paint film, which will not only damage the appearance, but also affect the corrosion resistance and weather resistance of the paint film. . Therefore, in order to prevent foaming during use, a defoamer should be added to the paint. The defoamer should have the following characteristics: 1. The surface tension of the defoamer should be smaller than that of the liquid to be defoamed; 2. The solubility in the liquid that needs to be defoamed should be as small as possible; 3. It should have good dispersibility ; 4. It cannot react wi...

Embodiment 1

[0124] Preparation method of component A:

[0125] a) Weigh 280kg of ZS-2601PUA resin from Guangzhou Zhuanshuo Chemical Technology Co., Ltd., 410kg of MMA monomer from Shandong Kaixuan Chemical Plant, 180kg of EA monomer from Shandong Kaixuan Chemical Plant, and 120kg of BA monomer from Shandong Kaixuan Chemical Plant. Evenly dispersed;

[0126] b) Weigh 2kg of Tego’s 900 defoamer and 2kg of EFKA’s 3277 leveling agent, and disperse evenly at high speed;

[0127] c) Weigh 4kg of Bh-a photosensitizer from Bengbu Shu Sunshine Curing Material Factory and 2kg of DM accelerator from Wuxi Yasheng Trading Co., Ltd., and disperse evenly at high speed;

[0128] d) The mixture obtained in c) is filtered to remove impurities and packaged.

[0129] Preparation method of component B:

[0130] a) Weigh 220kg of ZS-2601PUA resin from Guangzhou Zhuanshuo Chemical Technology Co., Ltd., 340kg of MMA monomer from Shandong Kaixuan Chemical Plant, 110kg of EA monomer from Shandong Kaixuan Chemic...

Embodiment 2

[0135] Preparation method of component A:

[0136] a) Weigh 265kg of PS9027PUA resin from Taiwan Changxing Chemical, 425kg of MMA monomer from American Bayer, 190kg of EA monomer from American Bayer, and 110kg of BA monomer from American Bayer, and disperse evenly at high speed;

[0137] b) Weigh 2kg of EFKA's 2721 defoamer and 2kg of EFKA's 3777 leveling agent, and disperse evenly at high speed;

[0138] c) Weigh 4kg of Cytec’s GC-58 photosensitizer and 2kg of Hangzhou Dongfang Technology’s TY-type accelerator, and disperse evenly at high speed;

[0139] d) The mixture obtained in c) is filtered to remove impurities and packaged.

[0140] Preparation method of component B:

[0141] a) Weigh 210kg of PS9027PUA resin from Taiwan Changxing Chemical, 355kg of MMA monomer from American Bayer, 105kg of EA monomer from American Bayer, and 105kg of BA monomer from American Bayer, and disperse evenly at high speed;

[0142] b) Weigh 135 kg of 800-mesh quartz powder wear-resistant f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com