Preparation method of matreel active peptide

An active peptide and mackerel technology, which is applied in the field of preparation of mackerel active peptides, can solve problems such as underutilization of mackerel's economic value, and achieve the effects of comprehensive amino acid composition, fast flow rate, and few side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

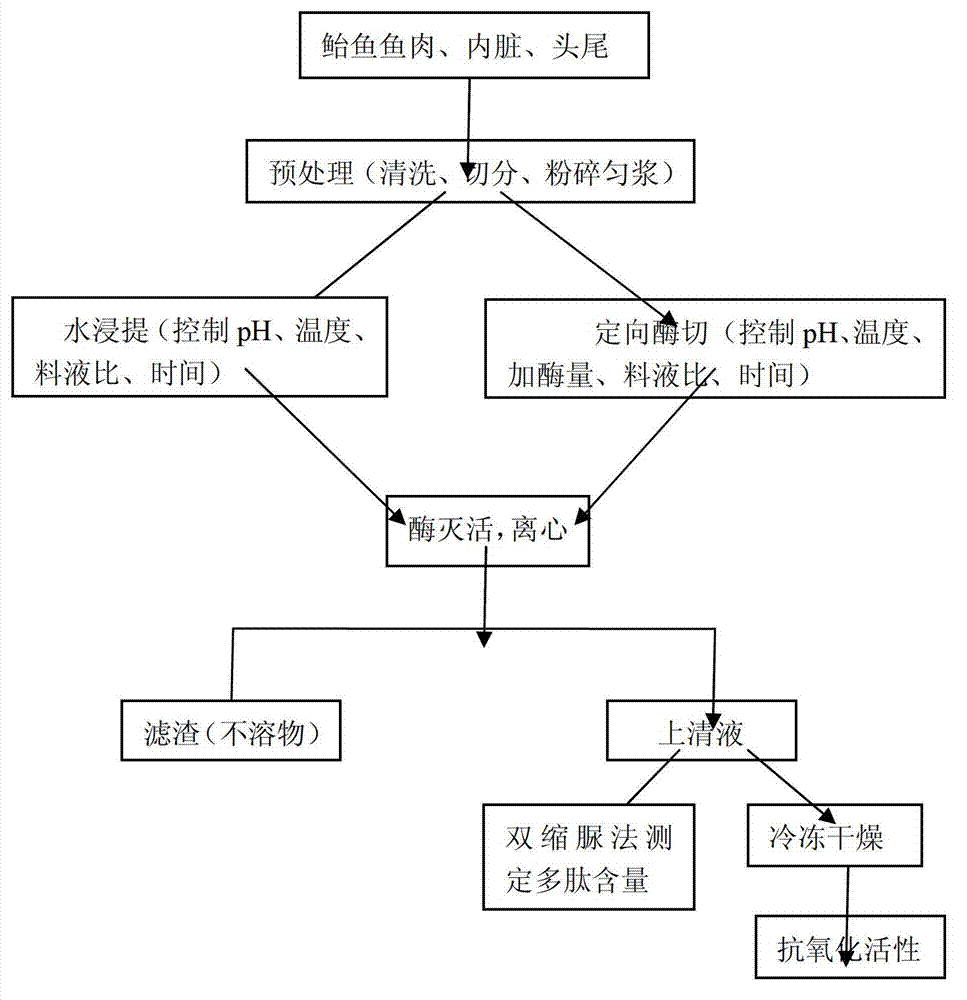

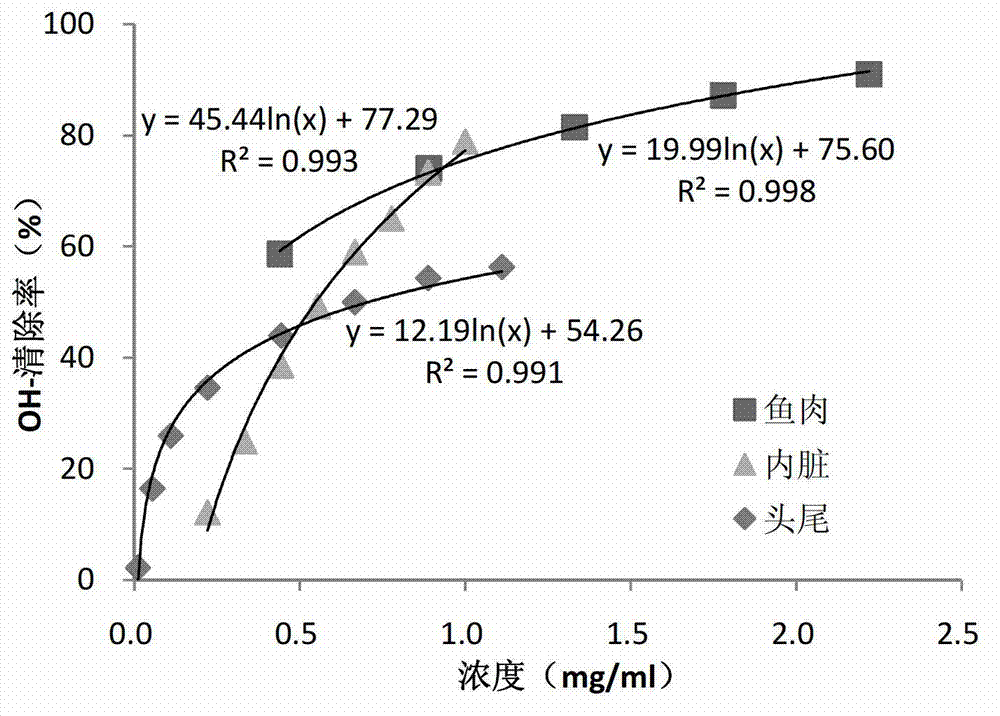

[0022] Preparation of Mackerel Active Peptide: Take mackerel fish meat, viscera, fish head and tail as raw materials, wash and mince, add a certain volume of deionized water, and stir continuously in an appropriate constant temperature water bath to achieve the optimum enzyme of protease After the solution temperature, keep it warm for about 5 minutes, and adjust the pH to the optimum value of each protease with 1 mol of NaOH or HCL. A certain amount of protease is added, hydrolyzed for a period of time, after the reaction is completed, the enzyme is inactivated, centrifuged, the supernatant is collected, freeze-dried, and mackerel active peptide is obtained.

[0023] In the preparation method of the above-mentioned mackerel active peptide, the ratio of adding deionized water is 1:10 to 1:20, and the proteases are respectively flavor protease, papain, neutral protease, trypsin and acid protease. All proteases mentioned above were purchased from Hubei Kangbaotai Fine Chemical C...

Embodiment 1

[0025] Take mackerel fish flesh 100g, wash mackerel fish flesh with deionized water, mash with high-speed mixer, gained surimi is mixed with water, add deionized water according to the ratio of mass ratio surimi: water=1:20, even The mass fraction of the substrate is 5%, and it is continuously stirred in a constant temperature water bath at 35°C. After reaching the optimum enzymatic hydrolysis temperature of neutral protease, it is incubated for about 5 minutes, and the pH is adjusted to 7.0 with 1mol of NaOH or HCL, and it is stirred continuously to Add 1746.4U / g enzyme activity unit per gram of surimi and add neutral protease to react for 5.5h. After the enzymatic hydrolysis, stop stirring, and rapidly raise the temperature to 95~100°C for 10 minutes to inactivate the enzyme, then adjust the pH of the slurry to neutral with acid or alkali, centrifuge at 4°C at low temperature (7000r / min, 20min), and put on The serum was stored at -20°C for later use.

[0026] The mackerel a...

Embodiment 2

[0028] Take by weighing two portions of mackerel fish meat each 10g, wash the mackerel fish meat with deionized water respectively, mash it with a high-speed mixer, mix the gained surimi with water, and add it according to the ratio of mass ratio surimi: water=1:20 Ionized water, that is, the mass fraction of the substrate is 5%. Stir continuously in a constant temperature water bath at 35°C. After a period of heat preservation, one part of it is adjusted to pH 7.0 with 1mol of NaOH or HCL, and continuously stirred. Add 1746.4U / g enzyme activity unit and add neutral protease to react for 5.5h. After the reaction is over, stop stirring respectively, and rapidly raise the temperature to 95-100°C for 10 minutes to passivate the enzyme, then use acid or alkali to adjust the pH of the slurry to neutral, centrifuge at 4°C at low temperature (7000r / min, 20min), and The supernatant was freeze-dried and stored for later use.

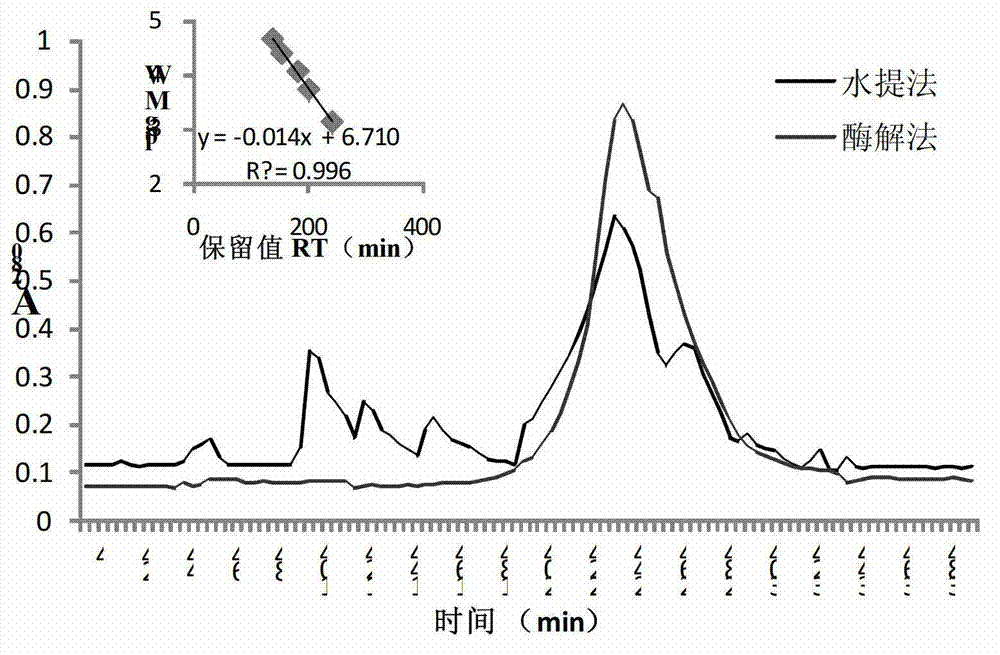

[0029] Put 10 mg of the lyophilized product on a gel colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com