All-round ultrahigh-toxicity micro-emission energy-saving waste gas and liquid purifying pulse engine master device

A technology of engine and waste liquid, which is applied in the direction of engine components, exhaust devices, combustion engines, etc., can solve the problem of less product discovery, achieve significant economic benefits, stable performance, and facilitate rapid popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

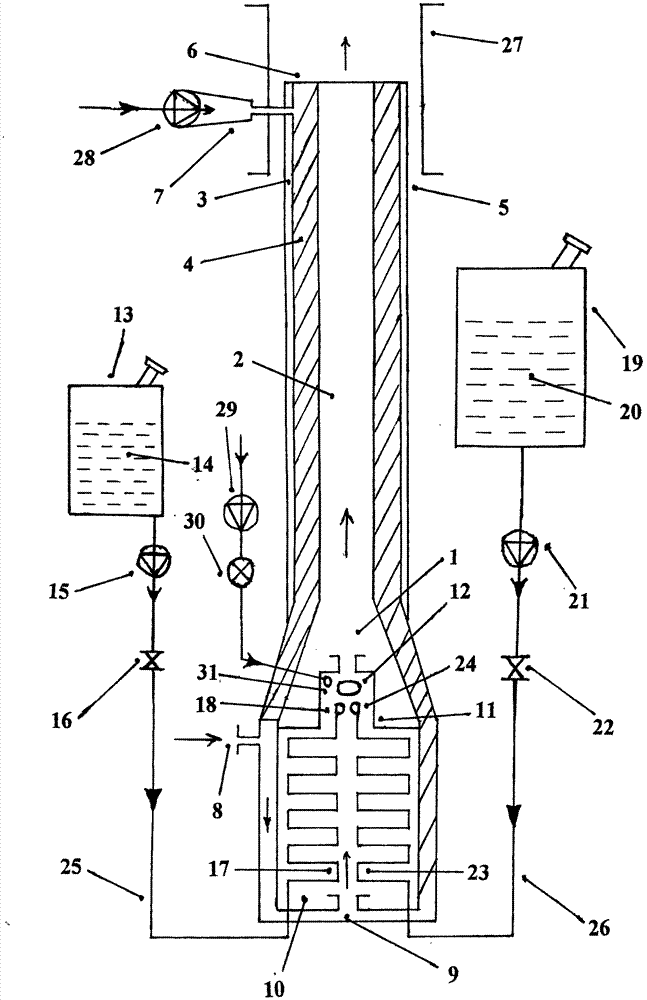

[0010] exist figure 1In the exhaust nozzle (2), the waste gas tail gas preheating porous medium regenerator pipe (3), high temperature porous medium regenerator (4), heat energy utilization working surface (5), exhaust pipe (6), Ultra-high toxic waste gas tail gas input pipe (7), low calorific value waste gas tail gas supercharger (28), a high-temperature porous media heat storage body (4) is installed in the waste gas tail gas preheating porous media heat storage body pipe (3), and the waste gas A thermal energy utilization working surface (5) is arranged outside the tail gas preheating porous medium regenerator tube (3), and a stable combustion outer cover pipe (27) is arranged outside the thermal energy utilization working surface (5). Set the heat energy utilization working surface (5) outside the pulsating high-temperature combustion chamber (1), the tail nozzle (2), and the waste gas tail gas preheating porous medium regenerator pipe (3), and set the tail end of the tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com