Super-resolution microscope method and device based on random fluorescence bleaching

A fluorescent bleaching and super-resolution technology, which is applied in the field of optical super-resolution microscopy, can solve the problem that fluorescent dyes cannot be directly applied, and achieve the effects of high system signal-to-noise ratio, simple structure, and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

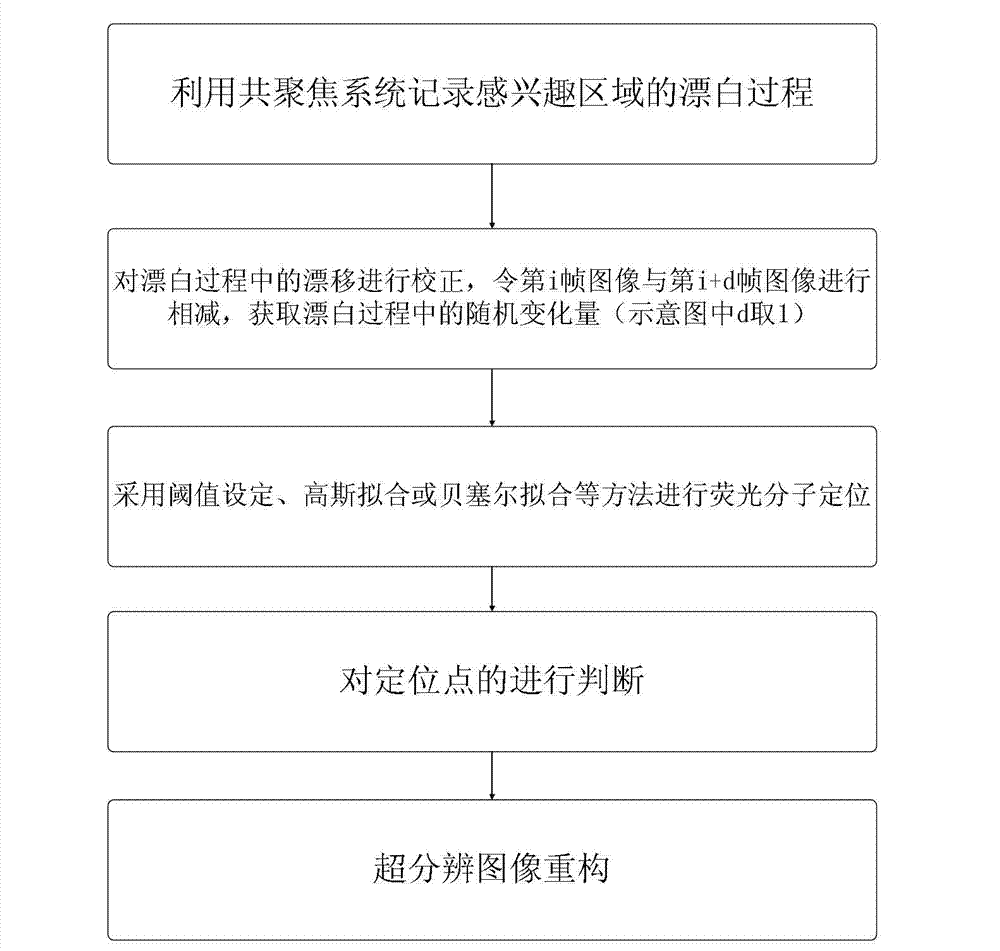

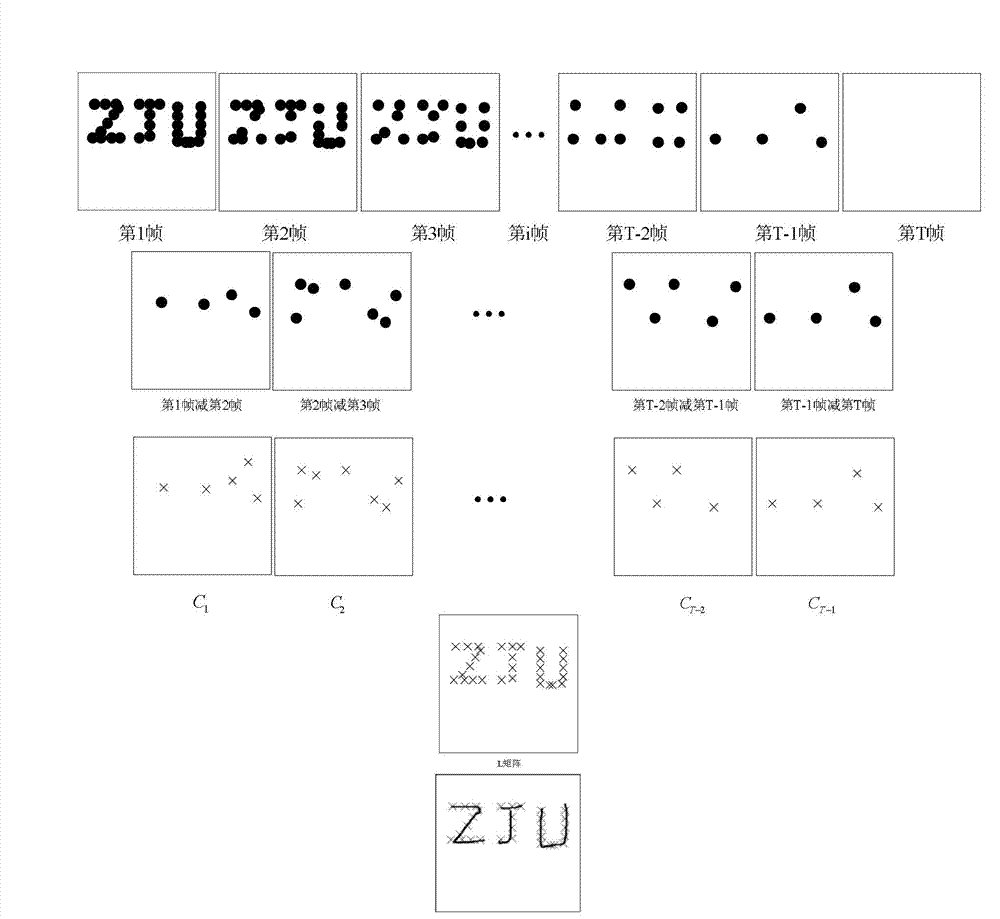

Method used

Image

Examples

Embodiment 1

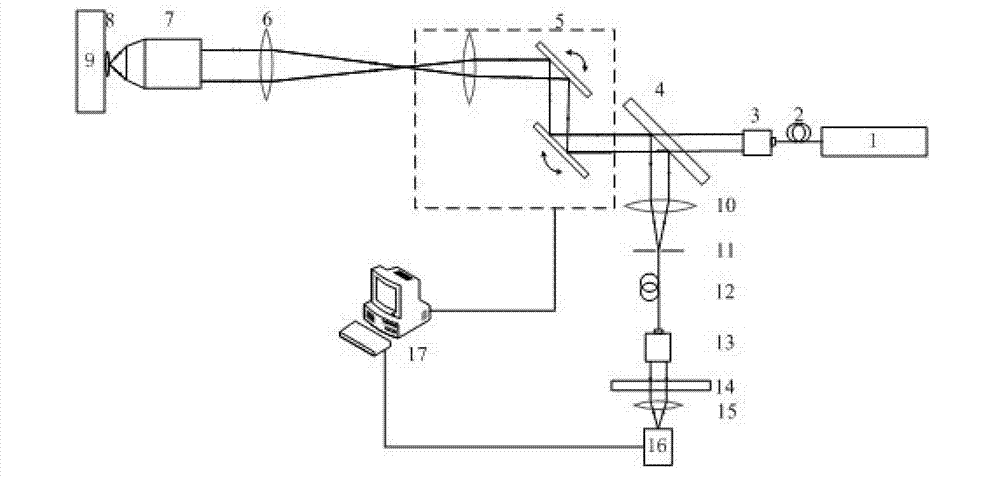

[0042] like image 3 As shown, a monochromatic super-resolution microscopy device based on random fluorescence bleaching, including: a laser 1, a single-mode fiber 2, a first fiber collimator 3, a dichromatic mirror 4, a scanning galvanometer system 5, and a field mirror 6 , microscope objective lens 7, sample to be measured 8, sample stage 9, first lens 10, pinhole 11, detection fiber 12, second fiber collimator 13, optical filter 14, second lens 15, photomultiplier tube ( PMT) 16, main control computer 17.

[0043] Among them, the laser 1 emits a laser beam, and the single-mode fiber 2, the first fiber collimator 3, the dichroic mirror 4, the scanning galvanometer system 5, the field lens 6, the microscopic objective lens 7 and the sample stage 9 are sequentially arranged in the optical path of the laser beam. on the optical axis. The first fiber collimator 3 collimates the laser beam, the dichroic mirror is used to transmit the excitation light and reflect the fluorescenc...

Embodiment 2

[0058] By adding an excitation light module and a detection module, it is possible to make Figure 4 The shown setup is used for two-color super-resolution microscopy based on stochastic fluorescent bleaching (for samples labeled with two fluorescent dyes, and it is required that the fluorescence wavelengths emitted by the two fluorescent samples are different). Figure 4 and image 3 In comparison, another excitation light module is placed at the excitation light end, including an additional laser 18, an additional single-mode fiber 19, an additional fiber collimator 20 and an additional dichroic mirror 21 matching the wavelengths of the two excitation lights, and the additional dichroic mirror The function of 21 is to make the two excitation lights coincide in space; at the same time, a detection module is correspondingly added at the detection end, including an additional PMT25, an additional lens 24, an additional color filter 23 and a detection dichroic mirror 22 matched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com