Method for improving performance of ethylene trimerization catalyst

An ethylene trimerization and catalyst technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of cumbersome implementation process and general catalyst activity, and achieves a simple and easy modification method. Ease of implementation and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 0.4861 g of chromium isooctanoate (0.001 mol of chromium) and dilute to 100 ml with dehydrated n-heptane, and the concentration of chromium in the solution is 0.01 mmol / ml. Prepare 100ml of n-heptane solution of 2,5-dimethylpyrrole, triethylaluminum and hexachloroethane in the same way, the concentrations are 0.03mmol / mL of 2,5-dimethylpyrrole and 0.5mmol / mL of triethylaluminum mmol / mL, hexachloroethane 0.05mmol / mL, spare.

Embodiment 2

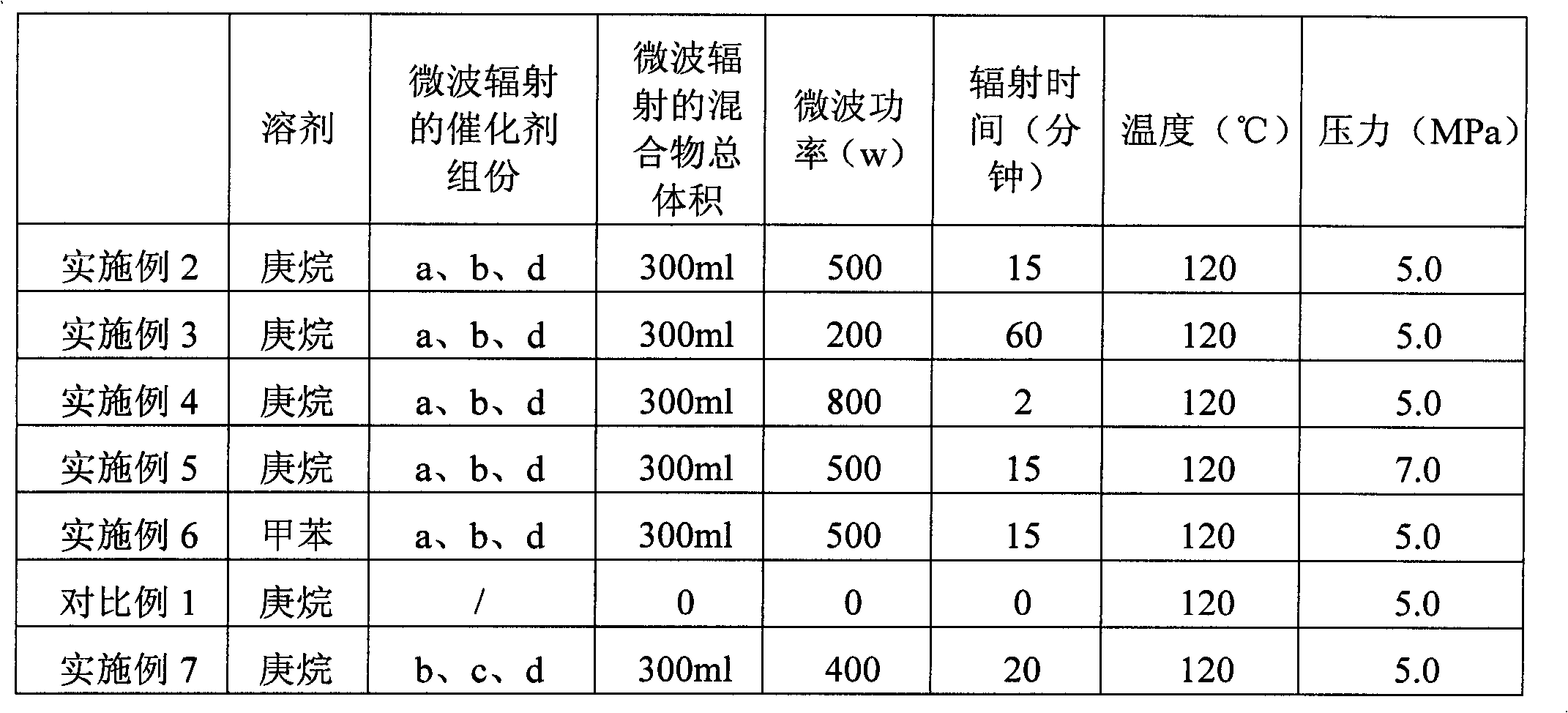

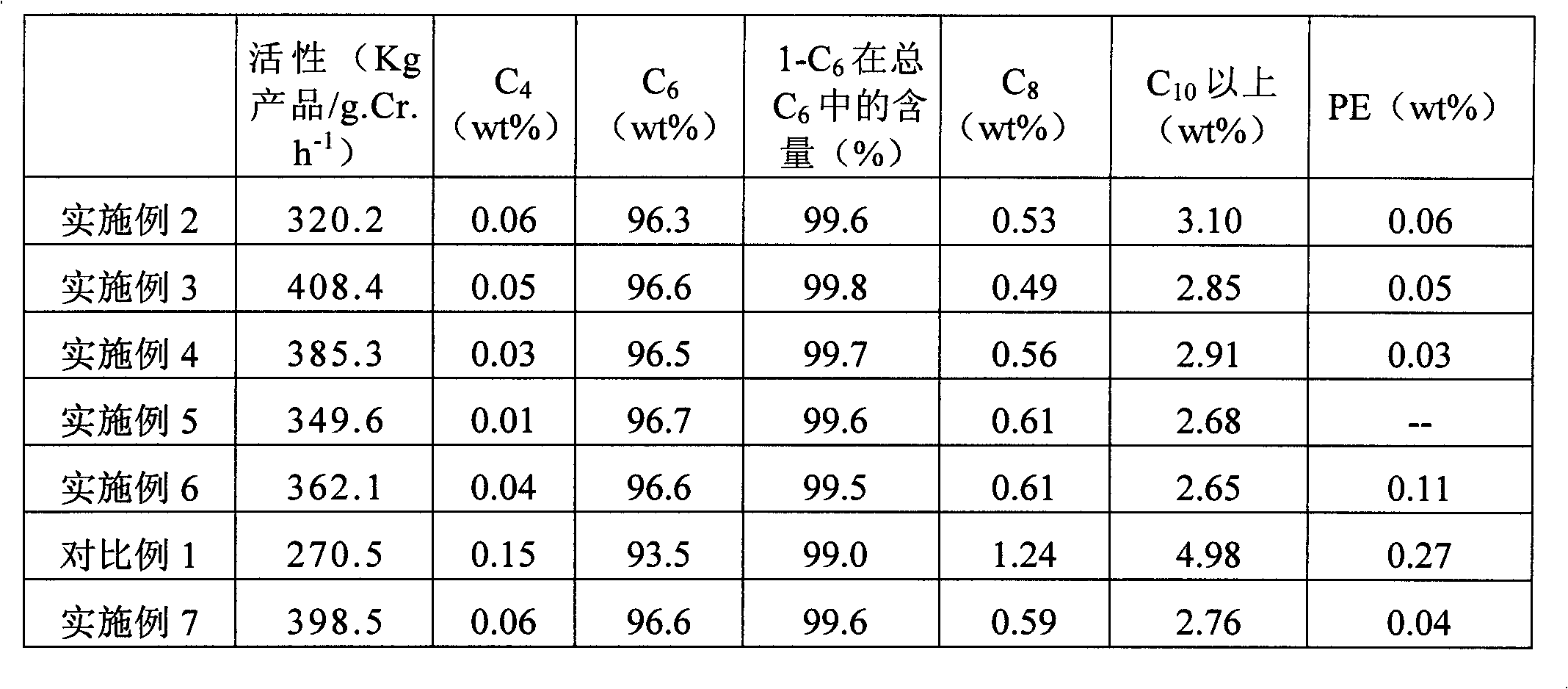

[0025] In a 500ml round bottom flask equipped with mechanical stirring and reflux condensation, add 100ml of chromium isooctanoate solution, 100ml of 2,5-dimethylpyrrole solution and 100ml of hexachloroethane solution prepared in Example 1, and place in microwave In the reactor, act for 15 minutes under the power of 500w.

[0026] A 300ml stainless steel polymerization kettle was used for the polymerization reaction. First, the pressure-holding test of the reactor was carried out. Under the condition that the seal of the reactor was confirmed to be intact, it was replaced three times with high-purity nitrogen and three times with high-pressure ethylene. Add 100ml of dehydrated n-heptane at room temperature, raise the temperature to 80°C, add 3ml of the above-prepared mixed solution and 1ml of triethylaluminum solution in sequence, start stirring, and immediately feed ethylene to trigger ethylene oligomerization, and the reaction system The temperature control is maintained at...

Embodiment 3

[0029] According to the operation and proportioning in Example 2, except that the microwave radiation power is 200w and the radiation time is 60 minutes, all the other conditions are the same as in Example 2. The results of ethylene trimerization are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com