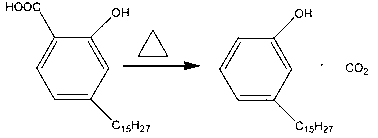

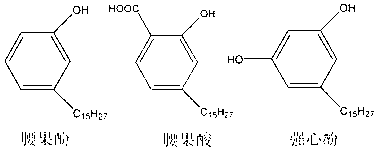

Cashew nut shell oil modified phenolic resin as well as preparation method and application thereof

A cashew nut shell oil and phenolic resin technology, applied in the field of synthetic resins, can solve the problems of non-renewable raw materials and high toxicity of phenol, and achieve the effects of renewable cost-effective, low toxicity and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A cashew nut shell oil modified phenolic resin, the raw material of which consists of the following components: 300g cashew nut shell liquid (1.0 mol), 78g paraformaldehyde (2.6 mol), 9.6g sodium hydroxide.

[0031] The preparation method of above-mentioned cashew nut shell oil modified phenolic resin comprises the following steps:

[0032] 1) Add cashew nut shell oil and sodium hydroxide in turn to the four-necked reaction flask, preheat to 60°C, then add paraformaldehyde in batches under stirring, and control the system temperature at 60-70°C at the same time, until the paraformaldehyde is completely dissolve, get a solution;

[0033] 2) Heat the solution to 90°C and react for 3 hours. During the reaction, a large number of water droplets appeared on the bottle wall, and the product was obtained with a yield ≥ 95%, unreacted cashew nut shell oil ≤ 1%, unreacted formaldehyde ≤ 4%, The viscosity at 25°C is 6521cps, and the solid content is 83%.

Embodiment 2

[0035] A cashew nut shell oil modified phenolic resin, its raw material is composed of the following components: 300g cashew nut shell liquid (1.0 mol), 84g paraformaldehyde (2.8 mol), 19.2g triethylamine.

[0036] The preparation method of above-mentioned cashew nut shell oil modified phenolic resin comprises the following steps:

[0037] 1) Add cashew nut shell oil and triethylamine to the reactor, preheat to 80°C, then add paraformaldehyde in batches under stirring, while controlling the system temperature at 70-80°C, and wait until the paraformaldehyde is completely dissolved to obtain solution;

[0038] 2) Heat the solution to 95°C and react for 6 hours. During the reaction, a large number of water droplets appeared on the bottle wall, and the product was obtained with a yield ≥ 95%, unreacted cashew nut shell oil ≤ 1%, unreacted formaldehyde ≤ 5%, The viscosity at 25°C is 9254cps, and the solid content is 81.5%.

Embodiment 3

[0040] A cashew nut shell oil modified phenolic resin, its raw material is composed of the following components: 300g cashew nut shell oil (1.0 mol), 194.6g formaldehyde solution (mass fraction 37%, of which formaldehyde is 2.4 mol), 3.7g sodium hydroxide.

[0041] The preparation method of above-mentioned cashew nut shell oil modified phenolic resin comprises the following steps:

[0042] 1) Add cashew nut shell oil and sodium hydroxide to the reactor, preheat to 70°C, then add formaldehyde solution dropwise under stirring, while controlling the system temperature at 70-80°C to obtain a solution;

[0043] 2) Heat the solution to 92°C and react for 2 hours. During the reaction, a large number of water droplets appeared on the bottle wall, and the product was obtained with a yield ≥ 95%, unreacted cashew nut shell oil ≤ 1%, unreacted formaldehyde ≤ 4%, The viscosity at 25°C is 5525cps, and the solid content is 84%.

[0044] Formaldehyde or paraformaldehyde is added in the syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com