Temperature control type monomer reactor

A reactor and monomer technology, which is applied in the field of temperature-controlled monomer reactors, can solve the problems of reduced hydrogen production efficiency, decreased catalyst activity, and high cost, and achieves the effects of inhibiting conversion rate, long reaction time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

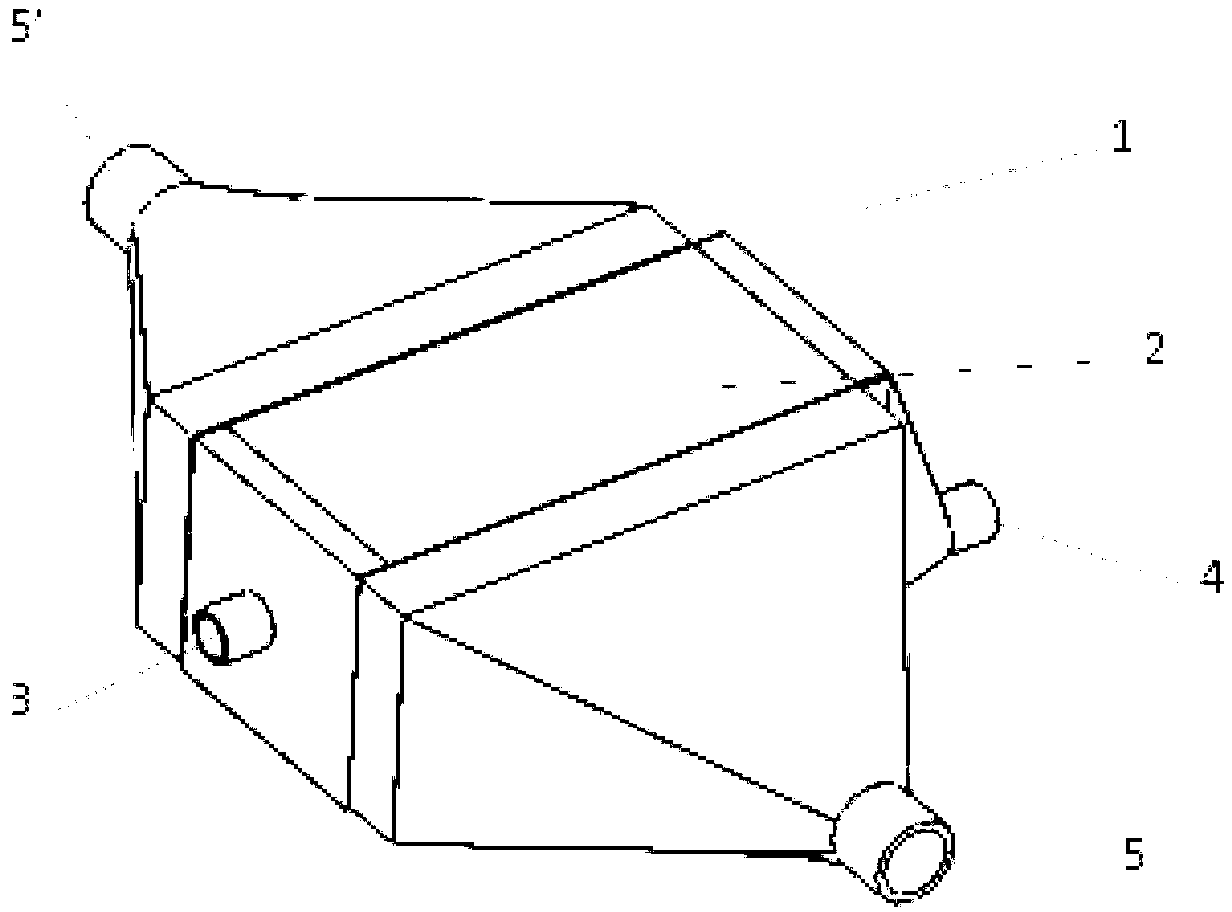

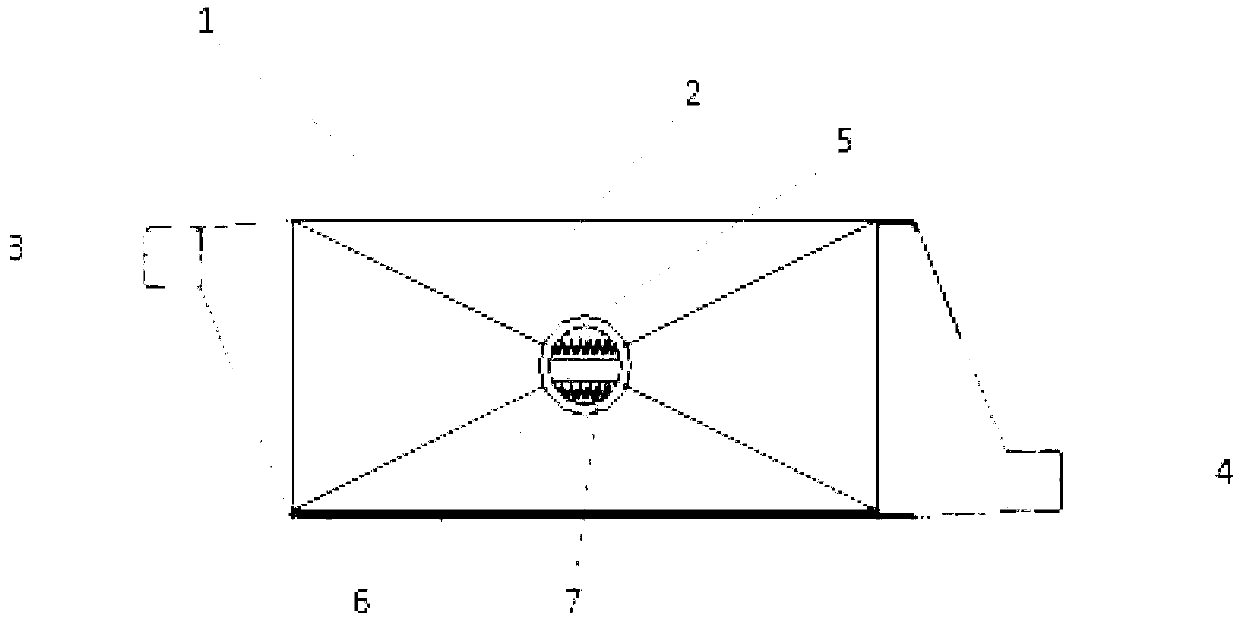

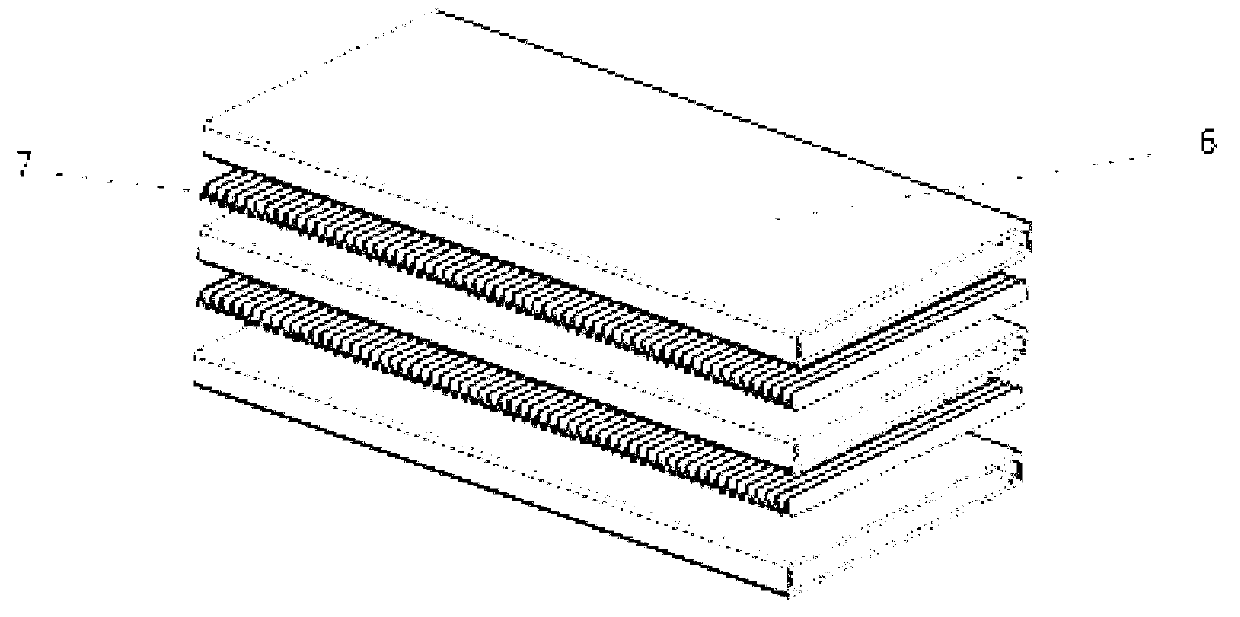

[0076] A temperature-controlled monomer reactor is provided, which is made of aluminum alloy, and the overall structure is as follows figure 1 As shown, there are 40 hollow main pipes (length-300mm; width-150mm; height-10mm, the wall thickness of the main pipe is 2mm) and 39 heat dissipation components (length-150mm; width-300mm; height-5mm; The orientation of the length and width of the heat dissipation component is different from that of the main pipeline), and there is no laminated aluminum alloy blade arranged in the main pipeline, and the arrangement structure of the main pipeline and the laminated aluminum alloy blades forming the heat dissipation component is as follows Image 6 As shown, the blade height is 5mm, the lamination width (interval between two laminations) is 3mm; a fan (model: W1G250HH6752-BA-ENG, purchased From Germany EBM PAPST); Catalyst adopts granular ruthenium catalyst (5% by weight / Al 2 o 3 , model: PM0400321, purchased from American Angle Co., Ltd...

Embodiment 2

[0078] A temperature-controlled monomer reactor is provided, which is made of aluminum alloy, and the overall structure is as follows Figure 9 As shown, there are 30 main pipes (length-500mm; width-150mm; height-10mm; the wall thickness of the main pipe is 2mm) and 29 heat dissipation components (length-200mm; width-500mm; height-5mm); each Laminated aluminum alloy blades are arranged in each main pipe, the height of the blade is 6mm, the width of the lamination is 4mm, and the length of the blade is 500mm; Figure 7A As shown, the height of each blade is 5mm, the lamination width is 3mm, and the length is 50mm; the two pairs of cooling holes of the reactor are respectively connected with two fans (model: PSD17051, purchased from Taiwan Jianzhun Company) ; The catalyst is ruthenium catalyst (model: PM0400321, purchased from Angle Co., Ltd., USA), coated on the inner wall of the main pipeline, the coating thickness is 0.5mm, the coating is silica sol containing ruthenium, and ...

Embodiment 3

[0080] Provide a reactor system, which is made of stainless steel, the overall structure is as figure 1 As shown, there are 40 main pipes (length-600mm; width-150mm; height-10mm; the wall thickness of the main pipe is 2mm) and 39 heat dissipation components (length-250mm; width-600mm; height-5mm), each Laminated aluminum alloy blades are arranged in each main pipeline, each blade height is 6mm, lamination width is 4mm, and blade length is 600mm; the arrangement of five laminated aluminum alloy blades forming a heat dissipation component is as follows Figure 8A As shown, the height of each blade is 5mm, the lamination width is 3mm, the length is 50mm, and they are arranged at 150° to each other; a fan (model: PSD17051, purchased from Taiwan Jianzhun Company); the catalyst adopts ruthenium catalyst (model: PM0400321, purchased from Angle Co., Ltd., USA), and is coated on the inner wall of the main pipeline with a coating thickness of 1.0 mm. The coating is aluminum sol containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com