Adhesive composition and semiconductor device using the same

A composition and adhesive technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of weak adhesion, wire drawing, and inability to obtain reliability at the gold-plated interface. Achieve high adhesion and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] Hereinafter, the present invention will be described in detail using examples, but the present invention is not limited by these examples. The materials used in the Examples and Reference Examples were produced or purchased as follows.

[0072] (1) Alcohols or carboxylic acids with a boiling point of 300°C or higher: stearic acid (boiling point: 376°C, Wako Pure Chemical Industries, Ltd.), tetraethylene glycol (boiling point: 327°C, hereinafter referred to as TEG, Wako Pure Chemical Industries, Ltd. Industrial Co., Ltd.), Isobornylcyclohexanol (boiling point: 308°C, hereinafter referred to as MTPH)

[0073] (2) Volatile components: dipropylene glycol dimethyl ether (boiling point: 175°C, hereinafter referred to as DMM, Daicel Chemical Co., Ltd.), γ-butyrolactone (boiling point: 204°C, hereinafter referred to as GBL, Sankyo Chemical Co., Ltd.), triethylene glycol butyl methyl ether (boiling point: 261°C, hereinafter referred to as BTM, Toho Chemical Industry Co., Ltd.),...

Embodiment 9

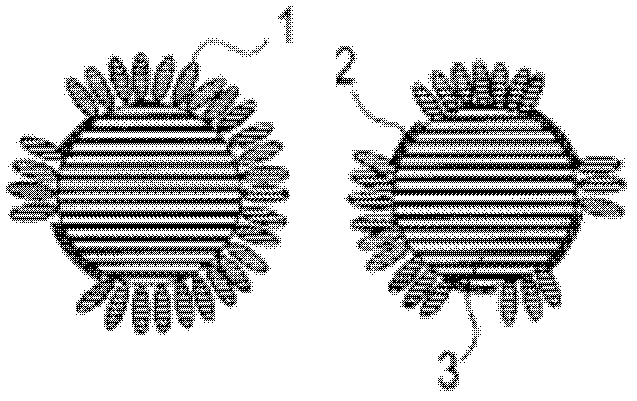

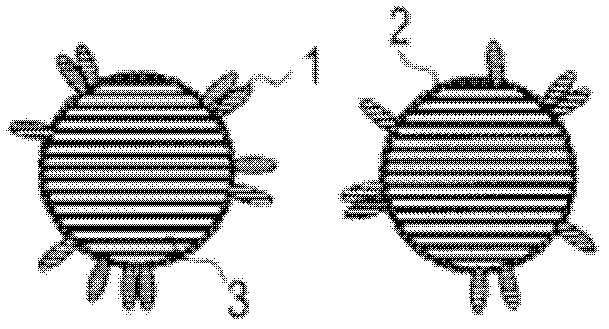

[0091] Use the adhesive composition of embodiment 1~8 that obtains above, manufacture such as Figure 7 semiconductor device shown. Specifically, the adhesive compositions of Examples 1 to 8 were coated on an Ag-plated Cu lead frame, an Au-plated semiconductor element was mounted thereon, and it was heat-treated in a clean oven at 180° C. for 1 hour, whereby the Semiconductor elements are attached to the lead frame. Thereafter, after going through a wire bonding process using Au wires, sealing is performed by a normal method, thereby manufacturing a semiconductor device.

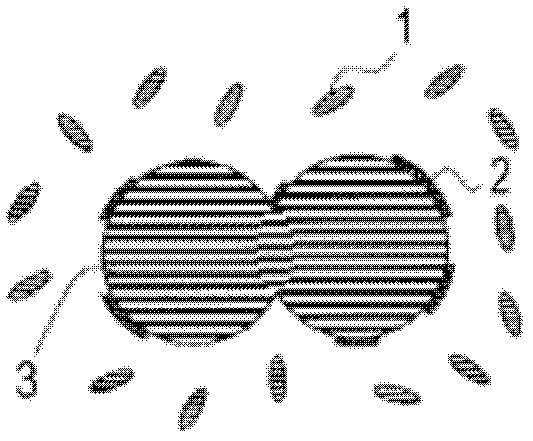

[0092] In addition, using the adhesive composition of Examples 1 to 8 obtained above, the following Figure 8 semiconductor device shown. Specifically, the adhesive compositions of Examples 1 to 8 were coated on an Ag-plated Cu lead frame, an Au-plated LED chip was mounted thereon, and it was heat-treated in a clean oven at 180° C. for 1 hour, whereby the The LED chip is attached to the lead frame. Ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com