Control method and device of laser-arc hybrid welding

A composite welding and control method technology, which is applied in laser welding equipment, arc welding equipment, electrode support devices, etc., can solve the problems of unable to correct attitude coordinates, huge influence on welding effect, and large robot changes, so as to improve welding efficiency and Adaptability, perfect welding, the effect of increasing the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

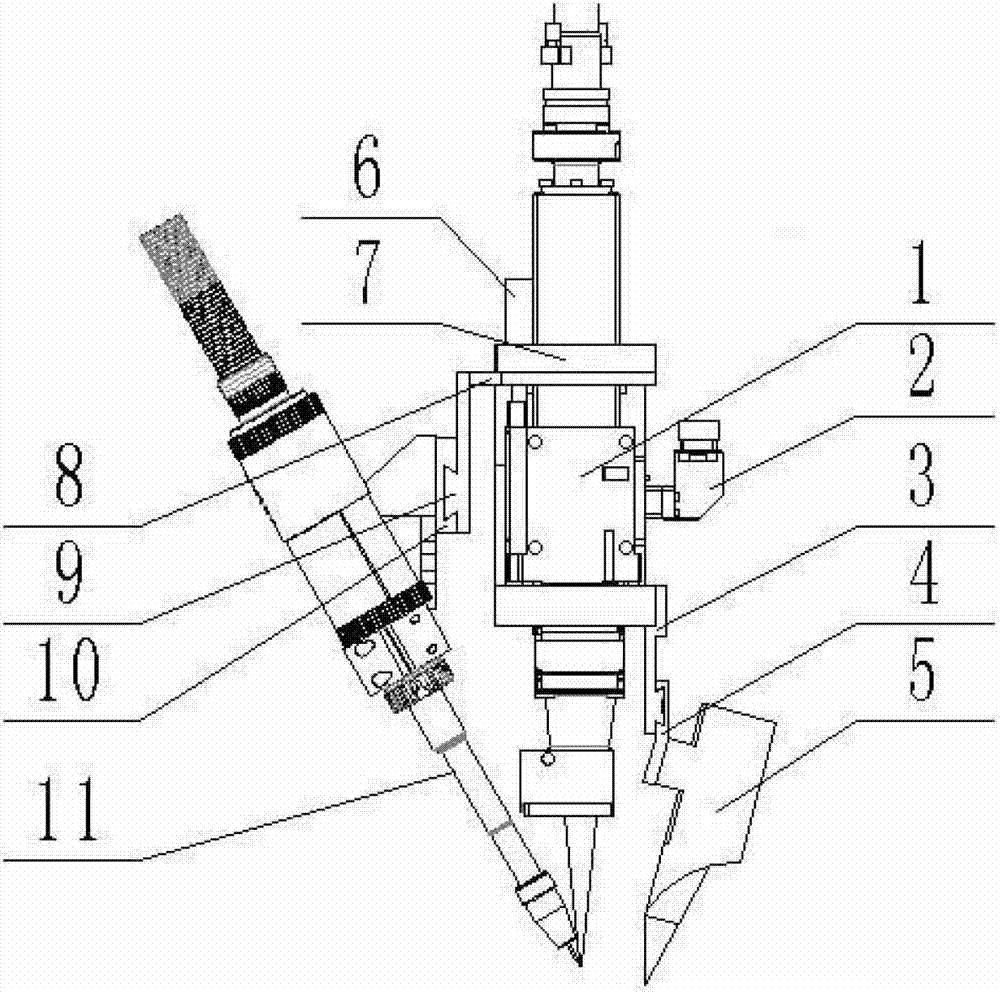

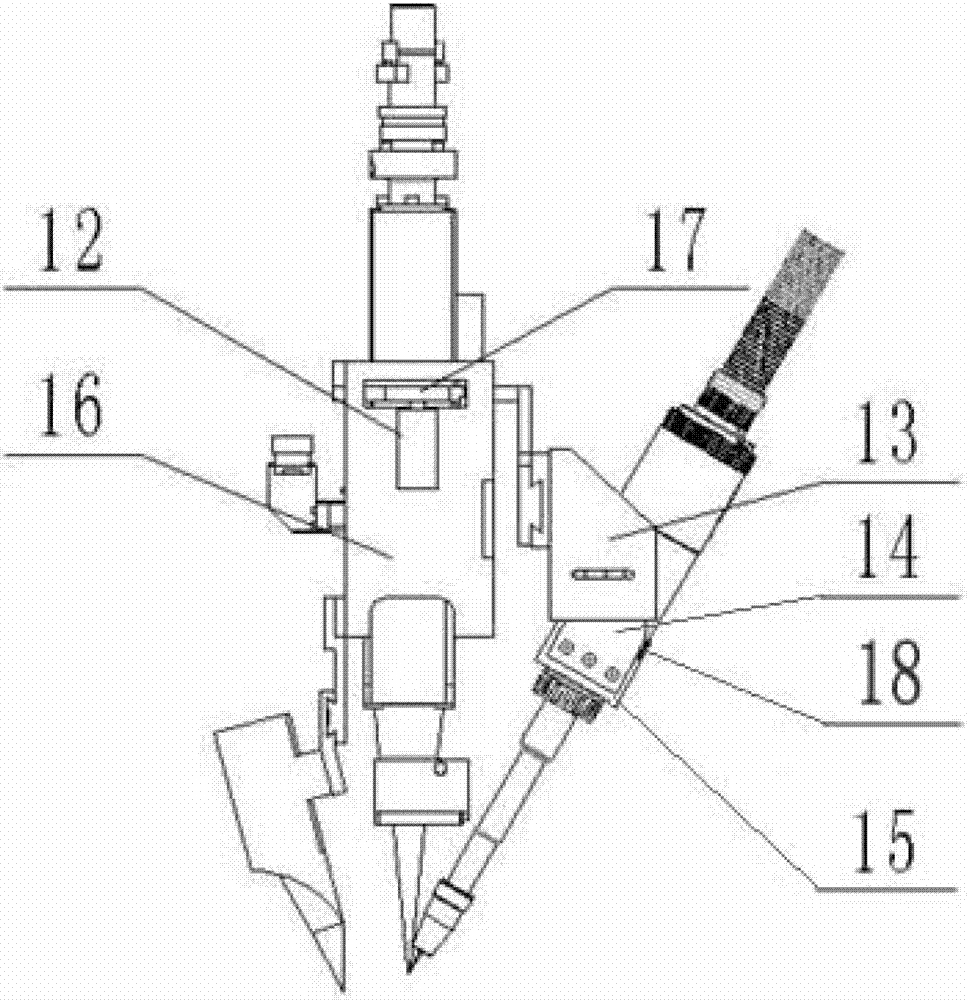

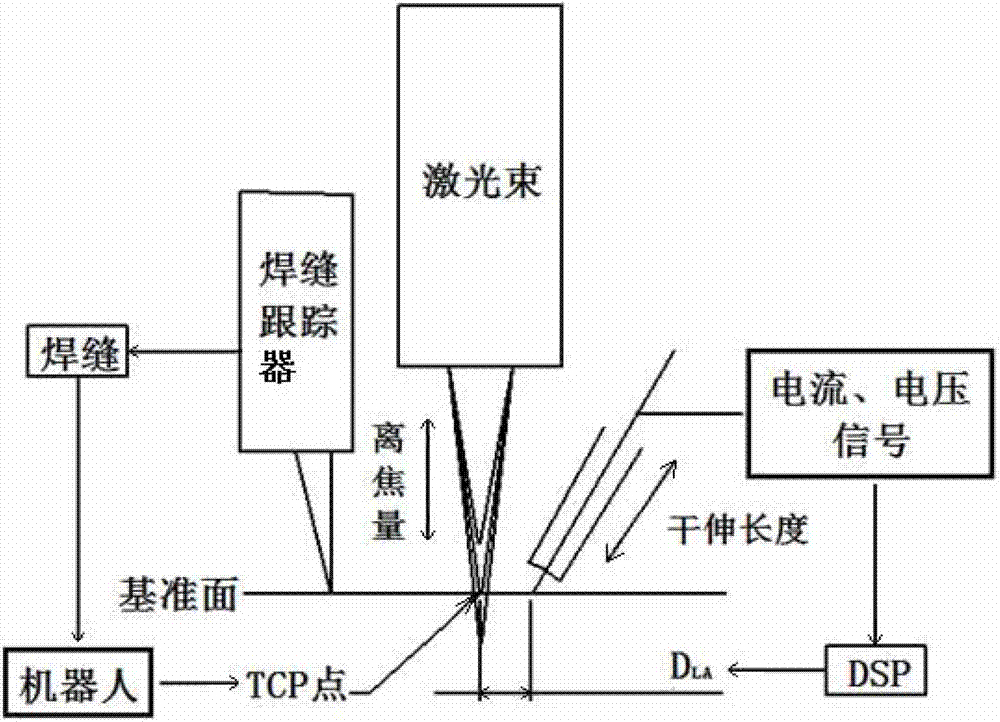

[0028] Such as figure 1 and figure 2 As shown, the device used in a control method of laser-arc hybrid welding of the present invention includes a laser welding head 1, a camera module 2, a seam tracker 5 and a welding torch 11, and one side of the laser welding head 1 is connected to the welding torch 11, one side of the laser welding head 1 is connected with the camera module 2 and the seam tracker 5; It is connected with the Z-axis sliding block through thread and positioning pin structure, and the top of the Z-axis sliding guide rail 16 is connected with the ring ball bearing 8 through the bearing connector 7, and it is determined that the ring ball bearing 8 is concentric with the laser beam; the upper part of the welding torch 11 By connecting the torch X-axis sliding guide rail 9 and the welding torch X-axis sliding block 10 with the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com