Synthesizing and recycling technology for waste plastic cement and recycled asphalt concrete

A technology for recycling asphalt and waste asphalt, applied in the field of asphalt concrete, waste plastic and recycled asphalt concrete synthesis and recycling, can solve problems such as affecting the use function of pavement, pavement reflection cracks, easy aging of roads, etc., achieve good elasticity and increase fluidity , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation process of waste plastic modified asphalt concrete is:

[0026] 1) Recycling waste plastics into rubber particles and recycled asphalt concrete at a mass ratio of 1:5.6 through rubber asphalt processing equipment to form rubber asphalt;

[0027] a) Rubber particles processed from waste plastics: 92% by weight of waste rubber floor particles (or waste tire particles), 4% carbon black, 2% calcium carbonate and 2% accelerator DM (chemical name : 2, 2'-dithiodibenzothiazole) mixed composition, passed through a 25 mesh sieve. The waste rubber floor particles are ethylene propylene rubber.

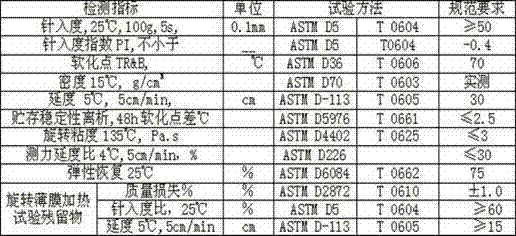

[0028] Table 1 Physical technical indicators of rubber particles processed from waste plastics

[0029] Pilot projects test results Required value Water content (%)0.55 less than 1 Metal particle content (%)00.05 Fiber content (%)0 less than 1 Relative density1.181.10-1.30

[0030] Table 2 Chemical technical indicators of rubber particles processed from waste plastics

[00...

Embodiment 2

[0061] It is basically the same as Example 1, except that the emulsifier uses cetyl trimethyl amine bromide. The described waste asphalt is added with 1.5% of the emulsifier, 0.2% of latex, 0.5% of asphalt oil, 0.5% of accelerator TT, and 0.3% of antioxidant D, which account for the total amount of filtered waste asphalt. And 0.3% carbon black, the above percentages are all mass percentages.

Embodiment 3

[0063] It is basically the same as Example 1, but the difference is: the emulsifier, 0.2% latex, 1% bitumen oil, 0.5% bitumen oil and 0.5% bitumen oil are added to the filtered waste bitumen. % Of accelerator TT, 0.3% of antioxidant D and 0.4% of carbon black, the above percentages are all mass percentages.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com