Metamorphite machine-made sand concrete capable of inhibiting alkali activity of metamorphite aggregate and preparation method thereof

A technology of metamorphic rock and machine-made sand, which is applied in the field of long-term durability of concrete and building materials, and achieves the effects of simple preparation method, reduced environmental damage, and reduced expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] To prepare C25 metamorphic rock aggregate machine-made sand concrete ingredients for bridges, roadbeds, tunnels and culverts in a project:

[0042] Fly ash: secondary fly ash;

[0043] Water reducing agent: Mapei polycarboxylic acid water reducing agent, the solid content is greater than 20wt%;

[0044] Air-entraining agent: sodium dodecylbenzene sulfonate;

[0045] Coarse aggregate: continuous graded metamorphic rock gravel, with a maximum particle size of 30mm, a needle-like particle content of 11.2wt%, a porosity of 29%, and a stone powder content of 7.3wt%;

[0046] Fine aggregate: Metamorphic rock machine-made sand, in which the content of stone powder is 7.3wt%.

[0047] Cement: Wumengshan P.O42.5 cement;

[0048] Lithium compound: LiOH;

[0050] water;

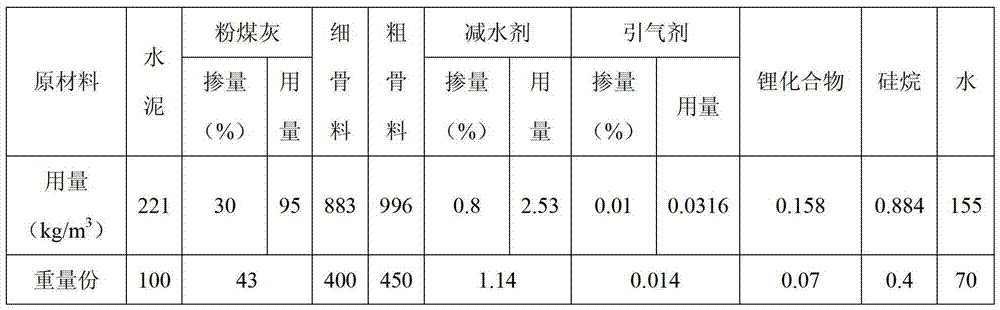

[0051] Table 1 Mix ratio of C25 metamorphic rock aggregate machine-made sand concrete

[0052]

[0053] The preparation process is: (1) Weigh the raw materials of each component according to the ratio; (2...

Embodiment 2

[0057] To prepare C30 metamorphic rock aggregate machine-made sand concrete ingredients for bridges, roadbeds, tunnels and culverts in a project:

[0058] Fly ash: secondary fly ash;

[0059] Water reducing agent: Mapei polycarboxylic acid water reducing agent, the solid content is greater than 20wt%;

[0060] Air-entraining agent: Rosin soap air-entraining agent;

[0061] Coarse aggregate: continuous graded metamorphic rock gravel, with a maximum particle size of 30mm, a needle-like particle content of 11.2wt%, a porosity of 29%, and a stone powder content of 7.3wt%

[0062] Fine aggregate: metamorphic rock machine-made sand, in which the content of stone powder is 7.3wt%;

[0063] Lithium compound: Li 2 CO 3 ;

[0064] Cement: Kaili Ruian P.O42.5 cement;

[0065] Silane emulsion; water;

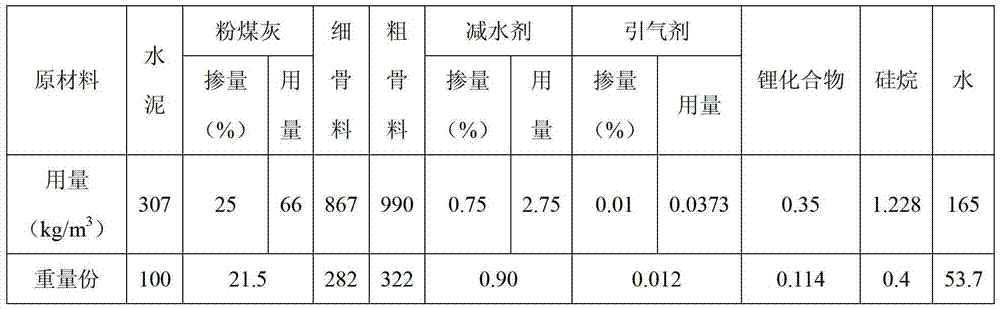

[0066] Table 2 Mix ratio of C30 metamorphic rock aggregate machine-made sand underwater concrete

[0067]

[0068] The preparation process is the same as in Example 1. At the same time, a standard test p...

Embodiment 3

[0071] To prepare C30 metamorphic rock aggregate machine-made sand pumping concrete batching for bridges, roadbeds, tunnels and culverts in a project:

[0072] Fly ash: secondary fly ash;

[0073] Water reducing agent: Mapei polycarboxylic acid water reducing agent, the solid content is greater than 20wt%;

[0074] Air-entraining agent: sodium lauryl sulfate;

[0075] Coarse aggregate: continuous graded metamorphic rock gravel, with a maximum particle size of 30mm, a needle-like particle content of 11.2wt%, a porosity of 29%, and a stone powder content of 7.3wt%;

[0076] Fine aggregate: metamorphic rock machine-made sand, in which the content of stone powder is 7.3wt%;

[0077] Lithium compound: Li 2 CO 3 ;

[0078] Cement: Kaili Ruian P.O42.5 cement;

[0079] Silane powder; water;

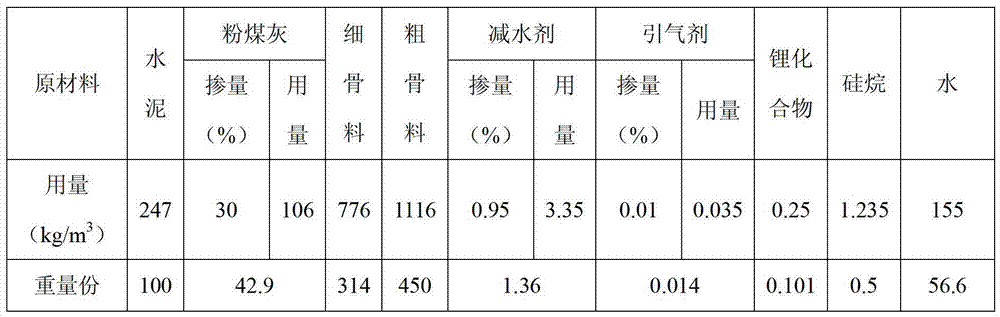

[0080] Table 3 Mix ratio of C30 metamorphic rock aggregate machine-made sand pumped concrete

[0081]

[0082] The preparation process is the same as in Example 1. At the same time, a standard test piece was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com