Method for preparing lubricant from biodiesel

A technology of biodiesel and epoxy biodiesel, which is applied in the fields of biofuel, lubricating composition, petroleum industry, etc., can solve the problems of affecting reaction balance, decreasing catalyst activity, low conversion rate, etc., and achieving moderate acid strength and low equipment corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

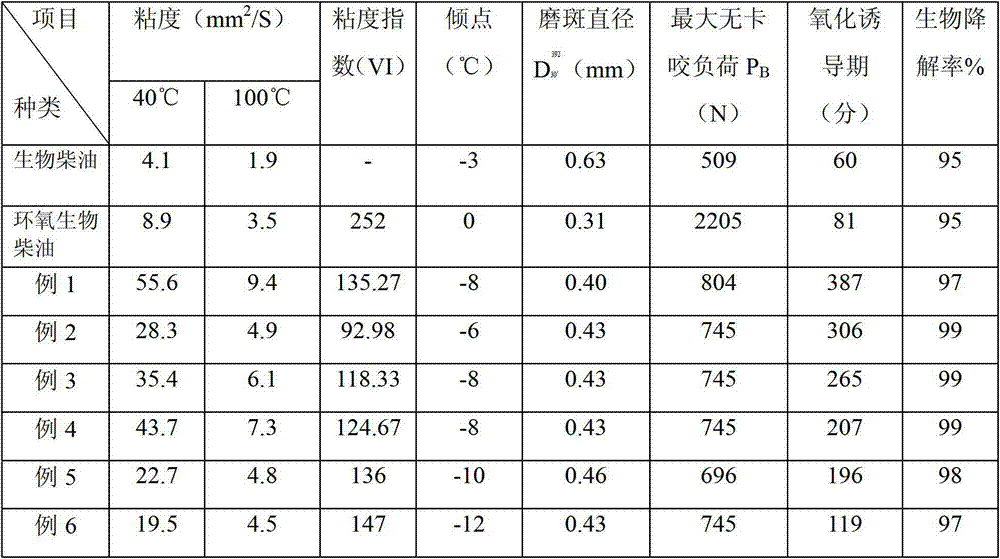

Examples

Embodiment 1

[0023] (1) Weigh 50g of soybean oil fatty acid methyl ester, 1g of solid acid catalyst ZSM-5-H molecular sieve and 3.5g of formic acid and put them in a three-necked flask with a condenser and a stirrer. Constant pressure funnel for hydrogen oxide, preheat to 40°C, stir, add dropwise, keep the temperature between 40-60°C, add hydrogen peroxide dropwise, finish adding dropwise in one hour, keep the temperature at 60-65°C, and then Continue to react at this temperature for 3.5 hours. After the reaction is completed, cool the reaction mixture to room temperature, pour it into a separatory funnel, and let it stand to separate the lower layer of water phase and solid acid catalyst; then use the upper layer of oil phase (organic phase) first 5% (solute mass fraction) NaHCO 3 The solution was washed 3 times, 50mL each time; then washed 3 times with 5% (solute mass fraction) NaCl solution, 30mL each time; finally, washed 3 times with hot distilled water (70°C), 50mL each time, and the...

Embodiment 2

[0029] (1) Weigh 50g of rapeseed oil fatty acid methyl ester, 1.5g of solid acid catalyst ZSM-5-Na molecular sieve and 4g of formic acid into a three-necked flask with a condenser and a stirrer, and insert a 20g A constant pressure funnel for hydrogen peroxide, preheat to 40°C, stir, add dropwise, keep the temperature between 40-60°C, add hydrogen peroxide dropwise, drop it in one hour, keep the temperature at 60-65°C, then Continue to react at this temperature for 4 hours. After the reaction is completed, cool the reaction mixture to room temperature, pour it into a separatory funnel, and let it stand to separate the lower layer of water phase and solid acid catalyst; then the upper layer of oil phase (organic phase) with 5% (solute mass fraction) NaHCO 3 The solution was washed 3 times, 50mL each time; then washed 3 times with 5% (solute mass fraction) NaCl solution, 30mL each time; finally, washed 3 times with hot distilled water (70°C), 50mL each time, and the pH after was...

Embodiment 3

[0032] (1) Weigh 50g of soybean oil fatty acid methyl ester, 1.5g of solid acid catalyst Y-type molecular sieve NaO 2 ·Al 2 o 3 4.9SiO2 2 9.4H 2 O and 3.5g of formic acid are placed in a three-necked flask with a condenser and a stirrer, one end of the bottle mouth is inserted into a constant pressure funnel containing 20.5g of hydrogen peroxide, preheated to 40°C, stirred, added dropwise, and the temperature is maintained at 40 Between -60°C, add hydrogen peroxide dropwise, the dropwise addition is completed in one hour, keep the temperature at 60-65°C, and then continue to react at this temperature for 3.5 hours. liquid funnel, let it stand, and separate the lower aqueous phase and the solid acid catalyst; then the upper oil phase (organic phase) was first washed with 5% (solute mass fraction) of NaHCO 3 The solution was washed 3 times, 50mL each time; then washed 3 times with 5% (solute mass fraction) NaCl solution, 30mL each time; finally, washed 3 times with hot disti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wear scar diameter | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com