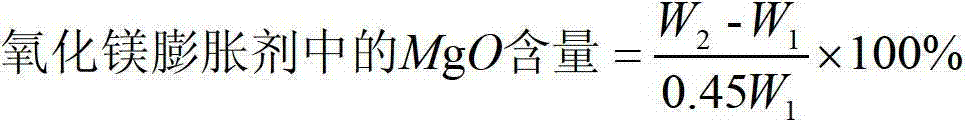

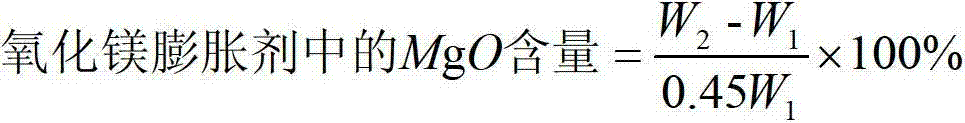

Method for testing content of magnesium oxide in magnesium oxide expanding agent

A test method and magnesium oxide technology, applied in the direction of removing a certain component and weighing, etc., can solve problems such as poor correlation, and achieve the effects of good reproducibility, simple experimental method and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take the magnesium oxide expansion agent provided by a magnesium oxide expansion agent manufacturer, pass the magnesium oxide expansion agent through a 0.08mm standard sieve, place it at 150°C for 2 hours, and place it in a desiccator to cool to room temperature. Weigh 5.0005 g of the pretreated magnesium oxide expansion agent sample, place it in a 200 ml reaction vessel, add 100 ml of prepared buffer solution with a pH value of 13.0, put a stirring bar, and cover with a watch glass. Place the reaction vessel in a water bath of a heat-collecting constant temperature magnetic stirrer. The temperature of the water bath is stabilized at 80°C±1°C. Turn on the magnetic stirrer and keep the speed at 750r / min~800r / min to make the magnesium oxide expansion agent sample and pH The buffer solution with a value of 13.0 was continuously reacted under these conditions for 5 hours, then taken out, filtered, rinsed and filtered with absolute ethanol, and put the rinsed filtered product...

Embodiment 2

[0035] Weigh analytically pure Mg(OH) 2 Sample 5.0011g was placed in a 200ml reaction vessel, and 100ml of buffer solution with a pH value of 13.0 was added, a stirring bar was placed, and a watch glass was covered. Place the reaction vessel in a water bath of a heat-collecting constant temperature magnetic stirrer. The temperature of the water bath is stabilized at 80°C ± 1°C. Turn on the magnetic stirrer and keep the speed at 750r / min to 800r / min to make the Mg(OH) 2 The sample and the buffer solution with a pH value of 13.0 were continuously reacted under these conditions for 5 hours, then taken out and filtered, and the filtered product was rinsed with absolute ethanol, and the rinsed filtered product was put into a porcelain crucible. Dry the porcelain crucible at 150°C to constant weight, place it in a desiccator and cool it to room temperature, weigh and measure the Mg(OH) after reacting with a buffer solution with a pH value of 13.0 2 The mass of the sample is 5.0016g...

Embodiment 3

[0041] High-grade magnesite (mainly composed of MgCO) produced in Haicheng, Liaoning 3 ), ground through a 0.08mm standard sieve, dried at 150°C for 2 hours, and cooled to room temperature in a desiccator. Weigh 5.0006 g of the pretreated magnesite sample, place it in a 200 ml reaction vessel, add 100 ml of prepared buffer solution with a pH value of 13.0, put a stirring bar, and cover with a watch glass. Place the reaction vessel in a water bath of a heat-collecting constant temperature magnetic stirrer. The temperature of the water bath is stable at 80°C±1°C. Turn on the magnetic stirrer and keep the speed at 750r / min-800r / min to make the magnesite sample and pH value The buffer solution with a concentration of 13.0 was continuously reacted under these conditions for 5 hours, then taken out, filtered, and the filtered product was rinsed with absolute ethanol, and the rinsed filtered product was put into a porcelain crucible. Dry the porcelain crucible at a temperature of 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com