Preparation method of liquid crystal pedot counter electrode for dye-sensitized solar cell

A technology for solar cells and dye sensitization, which is applied in the field of dye-sensitized solar cells, can solve the problems of high energy consumption in the preparation method, and achieve the effects of simple process, low price and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

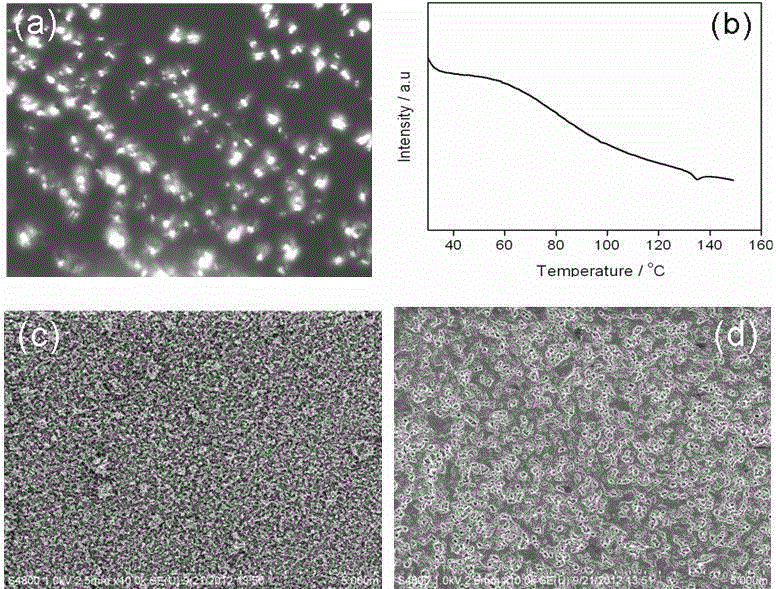

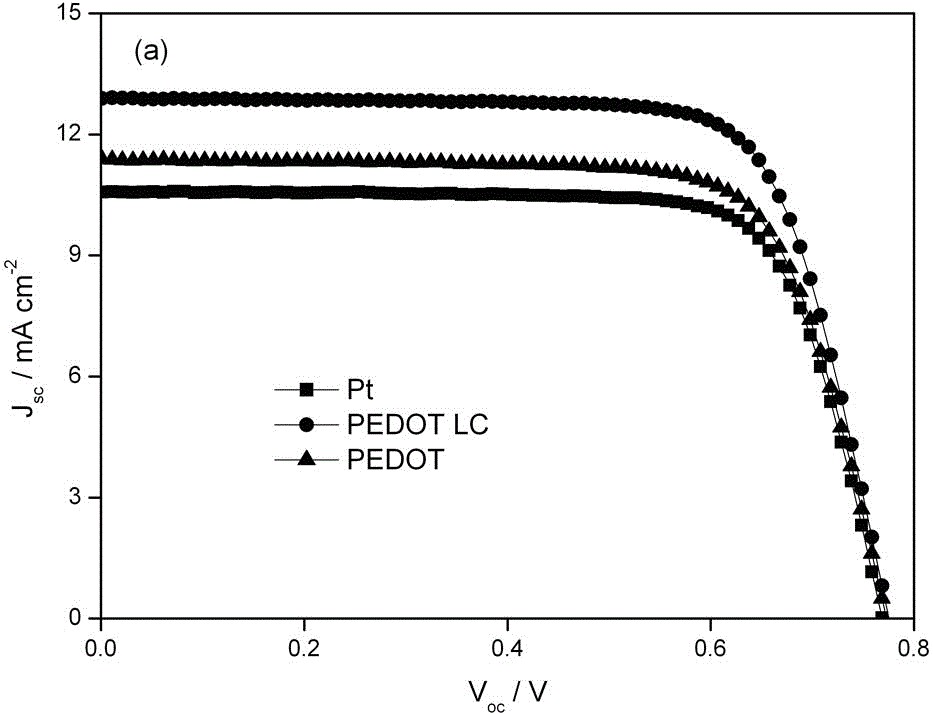

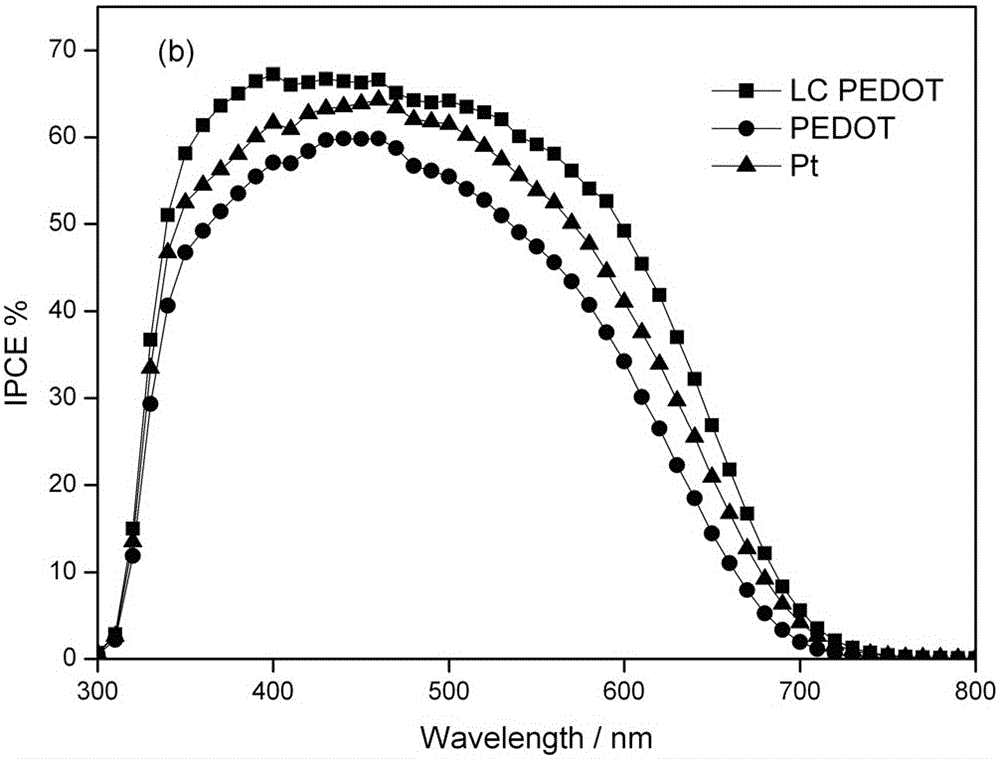

Image

Examples

Embodiment 1

[0024] Dissolve 50g of thiodiacetic acid in 250mL of boiling ethanol, then slowly add 20mL of concentrated sulfuric acid dropwise, reflux for 24h, cool, then pour the reactant into 300mL of water, extract 3 times with ether, then dry with anhydrous sodium sulfate, then The solvent can be removed by rotary evaporation to obtain a yellow oily liquid (compound 1 ) 57.2g, the yield was 83%.

Embodiment 2

[0026] With the compound of 25.3g embodiment 1 1 and 45.1mL diethyl oxalate were slowly added dropwise to 37.9g sodium ethoxide solution, then refluxed for 1h, then filtered and washed with ethanol to obtain the compound 2 , the yield is nearly 100%.

Embodiment 3

[0028] With the compound of 37.4g embodiment 2 2 Acidify with hydrochloric acid and water to obtain 20.7g of compound 3 , yield 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com