Water-in-oil type emulsified cosmetic and skin care method

An emulsified cosmetic, water-in-oil type technology, applied in the direction of cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve the problems of inability to obtain water resistance, poor durability, external stimulation, etc., and achieve excellent extension, stable emulsification, and film. Residual feeling suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1~8

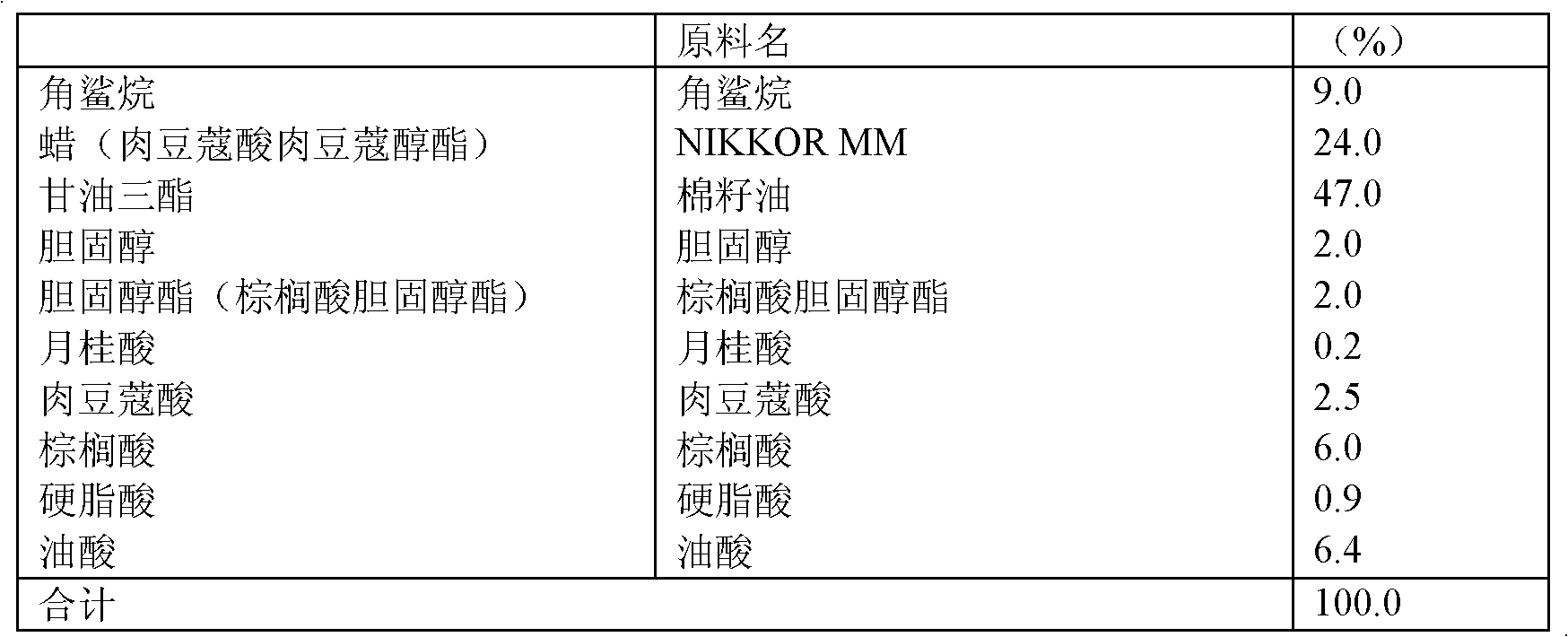

[0092] [Manufacturing method]

[0093] In Tables 1, 3, and 4, components (A) to (D) are used as phase I (oil phase) components, and component (E) is used as phase II (water phase) components. The ingredients of the first phase are mixed uniformly by the propeller stirring (500rpm) at room temperature according to the amount shown in Table 1, and the second phase II formed by dissolving and mixing is slowly added under stirring to emulsify, and the oil-in-oil mixture of the present invention is prepared. Water-based emulsified cosmetics 300g. In Table 2, after mixing in the same manner as in Tables 1, 3, and 4, they were treated with a homomixer at a rotation speed of 4,000 to 10,000 rpm for 10 minutes to prepare 300 g of the water-in-oil emulsified cosmetic of the present invention.

[0094] Evaluation methods and standards

[0095] Based on the following methods and standards, the water-in-oil emulsified cosmetics were evaluated for their barrier effect against external st...

Embodiment 2~8

[0165] Evaluation methods and standards

[0166] Based on the following methods and standards, the water-phase separation and time-dependent viscosity change rate of the prepared water-in-oil emulsified cosmetic were calculated.

[0167] (4) Water phase separation after shearing caused by stirring

[0168] The sample is stirred with a propeller / homomixer to prepare a sample. The state of the sample after preparation was visually observed and evaluated according to the following criteria.

[0169] evaluation standard

[0170] ○: No separation

[0171] ×: separation

[0172] (5) Time-dependent viscosity change rate after modulation

[0173] The sample immediately after preparation was put into a glass bottle (9.5 cm in height, 4.5 cm in inner diameter), and the viscosity was measured at a speed of 6 rpm with a B-type viscometer (BM type or TV-10 type manufactured by Toki Sangyo Co., Ltd.). After the sample was stored at room temperature for one month, the viscosity was me...

Embodiment 9~11 and comparative example 9~11

[0181] test methods

[0182] Based on the following method, the SPF value of the water-in-oil emulsified cosmetic was measured.

[0183] Each sample was treated with 2mg / cm 2 Spread evenly on a surgical tape on a quartz glass plate, let it dry for more than 20 minutes, and then measure the SPF value of the cosmetics with an SPF analyzer (Optometrics).

[0184] table 3

[0185]

[0186] Silicone treated titanium oxide * 9: SI-Titanium CR-50 (Titanium oxide treated with methylhydrogenpolysiloxane Miyoshi Chemical Co., Ltd.)

[0187] Silicone treated zinc oxide * 10: MZ-504 (methyl hydrogen polysiloxane treated zinc oxide TAYCA Co., Ltd.)

[0188] It is evident from the results in Table 3 that the water-in-oil emulsified cosmetic of the present invention can form an excellent film and obtain a more excellent ultraviolet protection effect.

[0189] Examples 12-30

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com