Graphene oxide microsphere and graphene microsphere and preparation methods thereof

A graphene and graphene sheet technology, applied in the field of nanomaterials or inorganic functional materials, materials science, can solve the problems of easy overlapping, inability to have a high specific surface area of graphene, application limitations, etc., and achieve easy availability of raw materials and production costs. Low, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Further, in order to obtain graphene microspheres, the aforementioned preparation method may further comprise the following steps:

[0042] (3) Reduction: hydrazine hydrate reduces graphene oxide microspheres to obtain graphene microspheres.

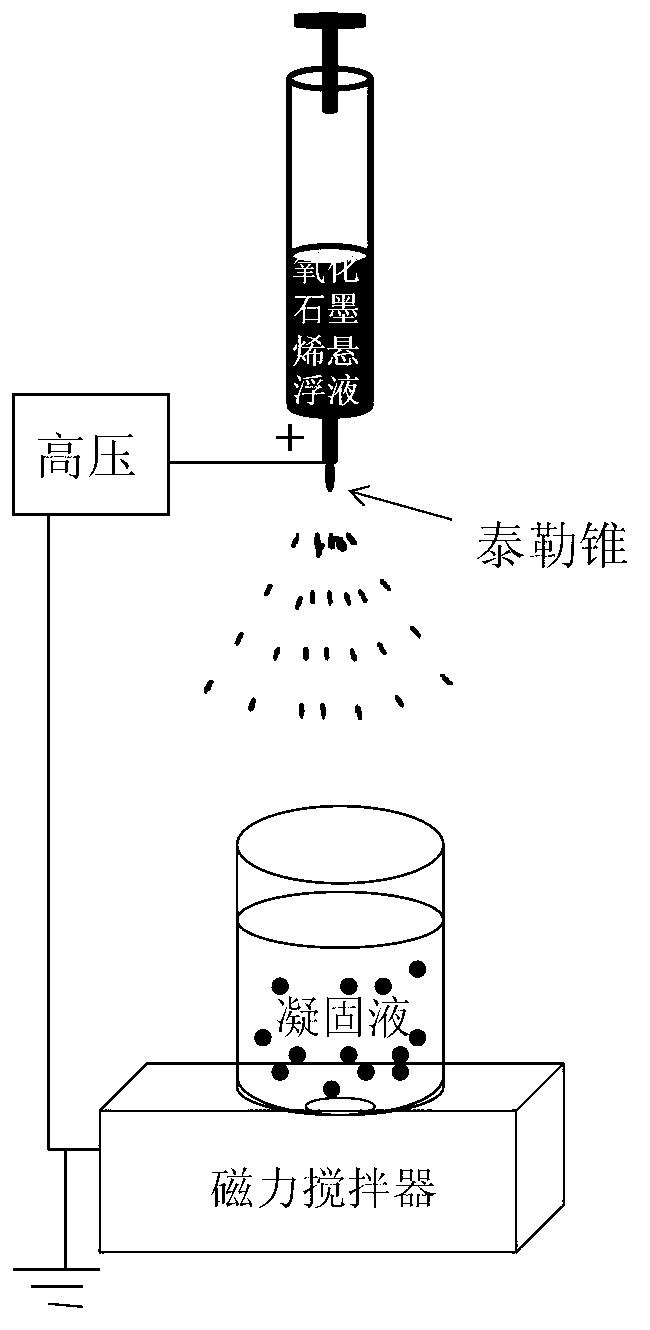

[0043] The voltage of the applied electric field in the aforementioned step (1) can be 0-30 KV to form an electrostatic field. The graphene oxide suspension droplet is kept in a crescent shape by its own surface tension at the outlet of the needle nozzle. When a high voltage is applied, under the induction of the electric field force, a large amount of charge is accumulated inside the graphene oxide suspension, and the droplet is subjected to a Electric field force in opposite direction of surface tension. As the electric field strength gradually increases, the droplet at the nozzle elongates from a spherical shape to a cone shape, which is called a Taylor cone. When the electric field strength continues to increase and the elec...

Embodiment 1

[0062] The 12.5 mg / ml graphene oxide suspension was electrosprayed and received by stirring with 0.35 mg / ml CTAB aqueous solution. Electrostatic spraying—wet collection devices such as figure 1 As shown, it includes propulsion device, static electricity generating device and receiving device. Inhale a certain amount of graphene oxide suspension into a 2 ml plastic syringe with a needle tip inner diameter of 0.50 mm. Connect the positive pole of the high-voltage power supply to the needle tip, and the coagulation liquid of the receiving device is grounded. A stable jet flow was formed under the conditions of a bolus injection speed of 0.05 mm / min and an applied voltage of 9 KV. When the stirring speed was 2 and the CTAB concentration was 0.35 mg / ml, the graphene oxide microspheres were received, and the graphene oxide hollow microspheres were obtained. The spheres were observed through a high-power optical microscope and a scanning electron microscope.

[0063] figure 2 It...

Embodiment 2

[0065] The 12.5 mg / ml graphene oxide suspension was electrosprayed and received by stirring with 0.55 mg / ml CTAB aqueous solution. Inhale a certain amount of graphene oxide suspension into a 2 ml plastic syringe with a needle tip inner diameter of 0.50 mm. Connect the positive pole of the high-voltage power supply to the needle tip, and the coagulation liquid of the receiving device is grounded. A stable jet flow was formed under the conditions of a bolus injection speed of 0.05 mm / min and an applied voltage of 9 KV. When the stirring speed was 2 and the CTAB concentration was 0.55 mg / ml, the graphene oxide microspheres were received, and the graphene oxide hollow microspheres were obtained. The sphere, partly graphene oxide erythrocyte-like structure, was observed with a high-power optical microscope and a scanning electron microscope.

[0066] Figure 4 It is an optical microscope photo of the above-mentioned graphene oxide microspheres. It can be seen from the figure that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com