Method for extracting and purifying astilbin

A technology of astilbin and extracting solution, which is applied in the field of extracting and purifying astilbin, which can solve the problems of reduced waste liquid discharge, low yield of astilbin, waste liquid discharge, etc., to reduce the discharge of three wastes, shorten the production cycle, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

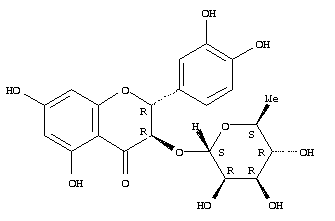

Image

Examples

Embodiment 1

[0024] Take 20 kg of leaves of Huang Qi, crush them into coarse powder, put them into an extraction tank, and soak them in 80% ethanol 10 times at 20°C for 5 hours. After the extract is released, immediately add 1% activated carbon for decolorization, filter, and recover ethanol under reduced pressure to obtain the extract, add 2 times the amount of water and stir to dissolve the extract. Let it cool, let it stand for 24 hours, collect the crystals, wash with water, and vacuum-dry to obtain 632 grams of crude astilbin. Add 3160 ml of ethyl acetate, stir for 30 minutes, filter, add 500 ml of ethyl acetate to the precipitate, stir for 30 minutes, filter, and dry to obtain 545 grams of total flavonoids of Huangqi, and the extraction yield of astilbin is greater than 60%.

Embodiment 2

[0026] Add 40 grams of total flavonoids of Huangqi, add 200 milliliters of water and 20 grams of borax, heat to dissolve completely, and let it cool. Add hydrochloric acid to adjust the pH value to 6, add sodium chloride to saturation, carry out salting out, and obtain a large amount of astilbinin boric acid complex precipitation. Filter the precipitate, add 10 times of acetone for ultrasonic extraction, until the paste precipitate is evenly dispersed into crystals, and then ultrasonic for 30 minutes. The precipitate was collected by filtration, and then ultrasonically extracted with 5 times the amount of acetone for 30 minutes, while stirring continuously. Filter the precipitate, add 5 times of water to the precipitate and stir evenly, add hydrochloric acid to acidify to pH 1, leave to crystallize for 24 hours, filter the precipitate, wash with water until neutral, dry to obtain 16 grams of astilbin, add 80 ml of acetone Dissolve, add 1% activated carbon to decolorize, conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com