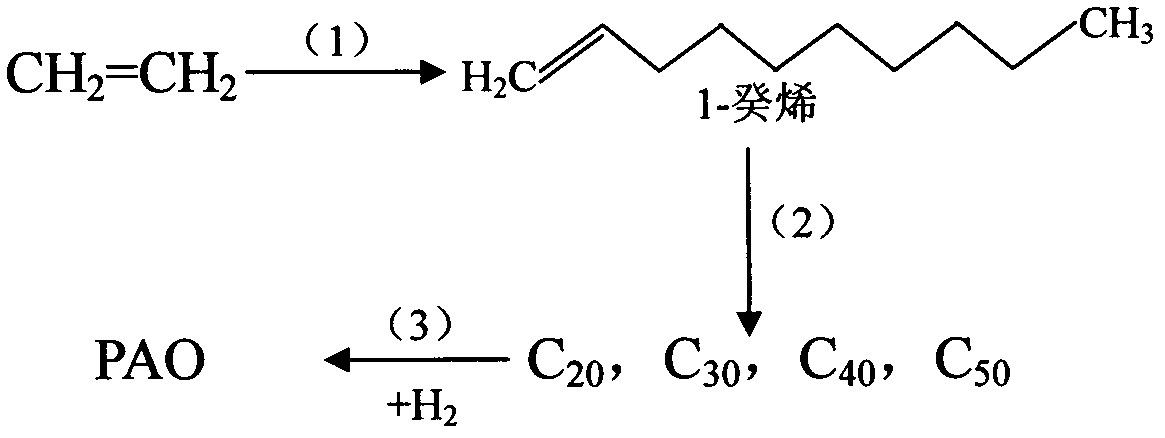

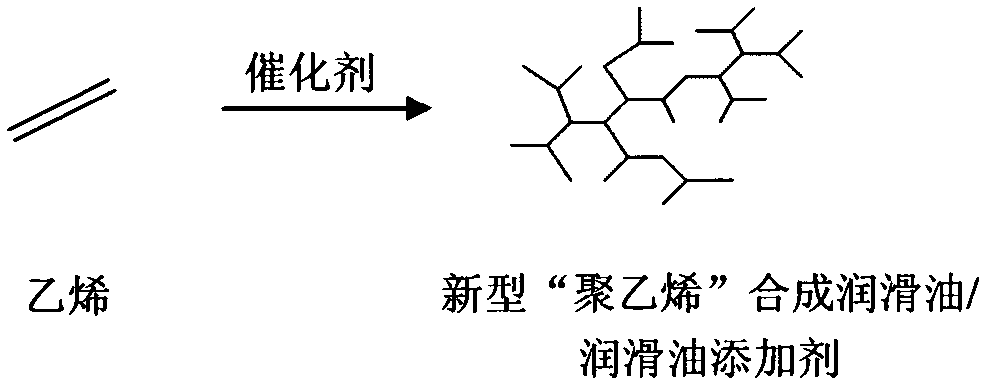

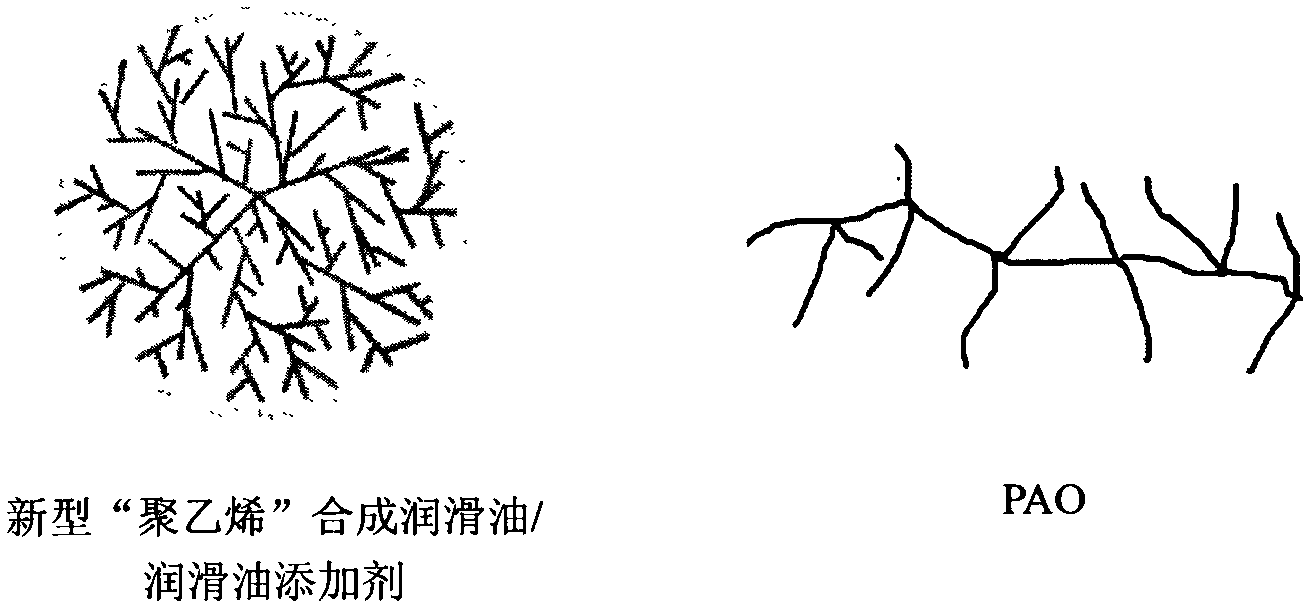

Novel polyethylene synthetic lubricating oil/lubricating oil additive and preparation method thereof

A lubricating oil additive and a technology for synthesizing lubricating oil are applied in the field of synthesis and preparation of new "polyethylene" synthetic lubricating oil/lubricating oil additive, achieving the effects of simple method, good solubility and high viscosity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The new "polyethylene" synthetic lubricating oil / lubricating oil additive developed by this patent is polymerized in a high-pressure reactor.

[0012] The first step is to prepare the catalyst for the polymerization of ethylene monomer in a vacuum glove box. All raw materials for the reaction must be dried to remove water and vacuumized to remove oxygen before use. Dissolve anhydrous aluminum chloride / titanium tetrachloride and treated nano silicon dioxide / aluminum trioxide / magnesium chloride powder in 10-100mL dehydrated toluene / chlorobenzene / dichloromethane / chloroform and other organic In the solvent, stir under nitrogen environment and slowly add a certain amount of diethylaluminum chloride / ethylaluminum dichloride solution, aluminum chloride / titanium tetrachloride and nano silicon dioxide / aluminum trioxide / The mass ratio of magnesium chloride is 0.5:1.0~4.0:1.0, the molar ratio of aluminum chloride / titanium tetrachloride to diethylaluminum chloride / ethylaluminum di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com