Extraction agent capable of effectively improving manganese extraction effect and extraction method

An extraction agent and extraction technology, applied in the field of non-ferrous metallurgy, can solve the problems of low manganese extraction rate and poor selectivity, and achieve effective separation, good selectivity, and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

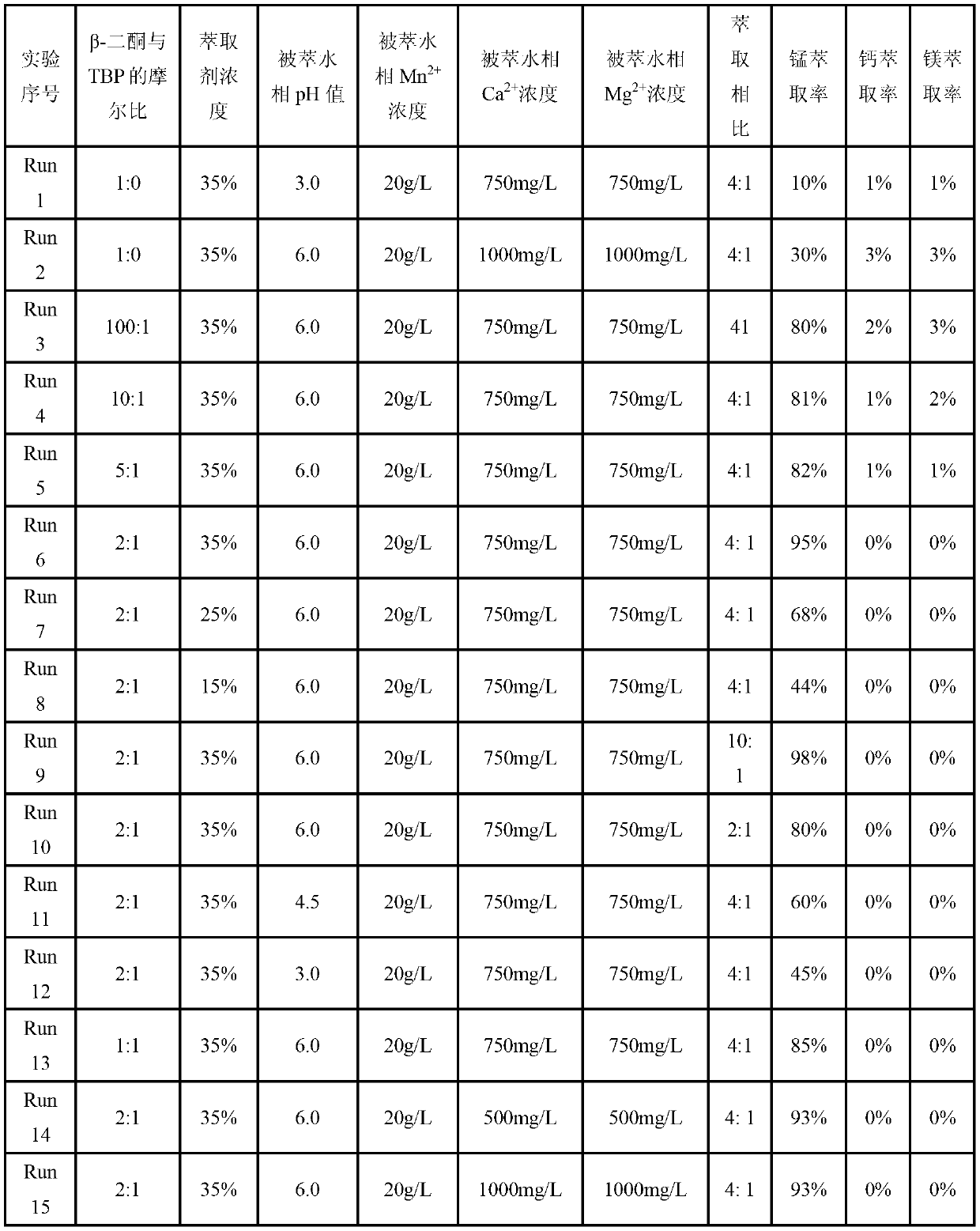

[0026] Effect of adding tributyl phosphate (TBP) to high sterically hindered β-diketone on the extraction rate of manganese, calcium and magnesium from manganese sulfate solution containing calcium and magnesium

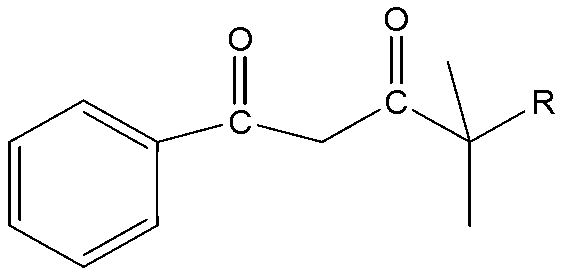

[0027] Add TBP to high sterically hindered β-diketone (with the structure described in the extractant mentioned in the "Summary of the Invention", R is an alkyl group with 6 carbon atoms, referred to as β-diketone) to form an extractant (wherein β - The molar ratio of diketone to TBP is 1:1 to 1:0), using sulfonated kerosene as diluent to prepare the extractant to a concentration of 15% to 35% to form an organic phase (ie oil phase). Manganese sulfate solution containing calcium and magnesium is prepared as the extracted water phase, and its Mn 2+ The concentration is 20~40g.L -1 range, Ca 2+ and Mg 2+ The concentration is 500~1000mg.L -1 range, the pH value is 3.0-6.0. Extraction operation: add the oil phase and the extracted water phase into a 250ml conical fl...

Embodiment 2

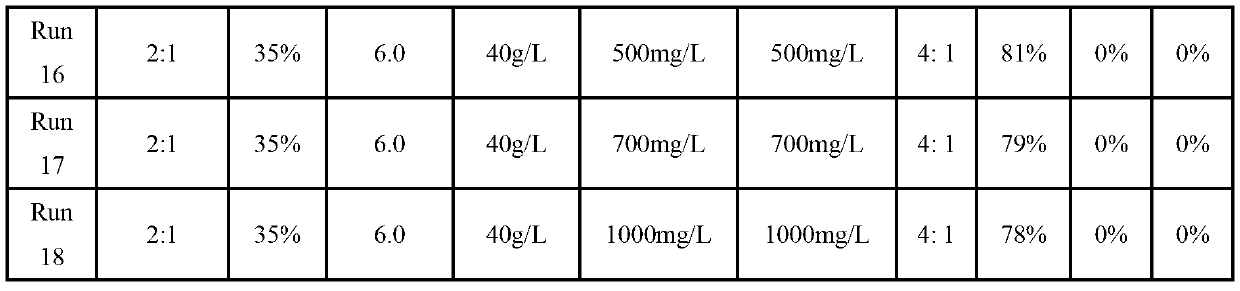

[0033] Example 2 The effect of adding n-octanol on the extraction rate of manganese, calcium and magnesium in the manganese sulfate solution containing calcium and magnesium to the high steric hindrance β-diketone

[0034] Add n-octanol to high sterically hindered β-diketone (with the structure described in the extractant mentioned in the "Summary of the Invention", R is an alkyl group with 10 carbon atoms, referred to as β-diketone) to form an extractant ( Among them, the molar ratio of β-diketone to n-octanol is 1:1~1:0), using sulfonated kerosene or 260# solvent oil as diluent to prepare the extractant to a concentration of 15%~35% to form an organic phase ( the oil phase). Manganese sulfate solution containing calcium and magnesium is prepared as the extracted water phase, and its Mn 2+ The concentration is 20~40g.L -1 range, Ca 2+ and Mg 2+ The concentration is 500~1000mg.L -1 The range of pH is 3.0 to 6.0. Extraction operation: Add the oil phase and the extracted w...

Embodiment 3

[0040] Example 3 Effect of adding tri-n-octylphosphine oxide (TOPO) to high sterically hindered β-diketone on the extraction rate of manganese, calcium and magnesium in manganese sulfate solution containing calcium and magnesium

[0041] Add tri-n-octylphosphine oxide ( TOPO) to form an extractant (wherein the molar ratio of β-diketone to TOPO is 1:1 to 1:10), using sulfonated kerosene as a diluent to prepare the extractant to a concentration of 15% to 35% to form an organic phase (ie oil phase). Manganese sulfate solution containing calcium and magnesium is prepared as the extracted water phase, and its Mn 2+ The concentration is 20~40g.L -1 range, Ca 2+ and Mg 2+ The concentration is 500~1000mg.L -1 The range of pH is 3.0 to 6.0. Extraction operation: Add the oil phase and the extracted water phase into a 250ml conical flask with a stopper, then put the conical flask into a super constant temperature shaker for 30 minutes, and pour the mixture in the conical flask Int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com