Device used for sintering sodium-sulfur battery ceramic pipes

A sodium-sulfur battery and ceramic tube technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of increasing the complexity of the firing process, poor alkali corrosion resistance, and short life of the sintering kiln. Furnace loading time and labor costs, good uniformity, and the effect of saving development and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments in conjunction with the accompanying drawings:

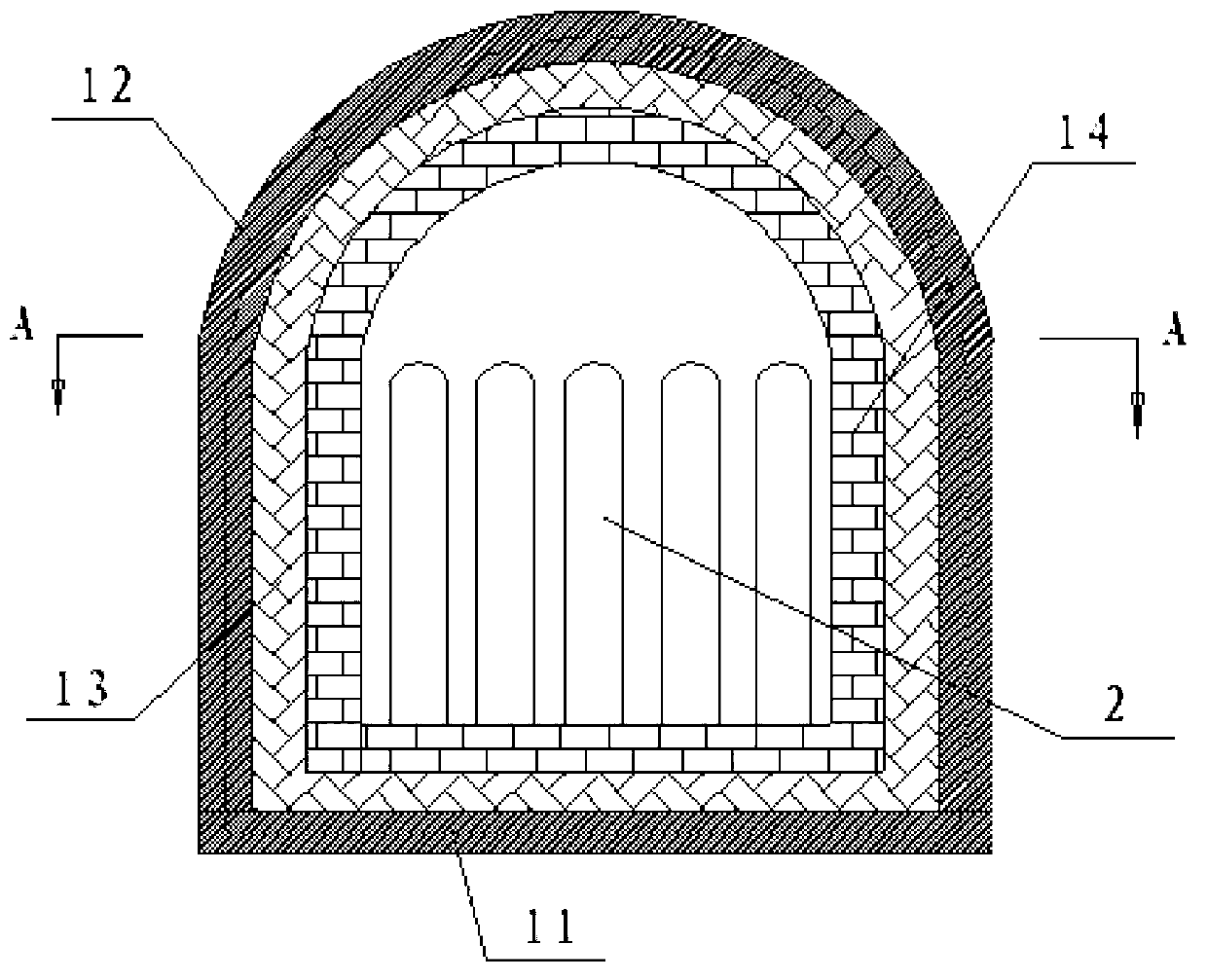

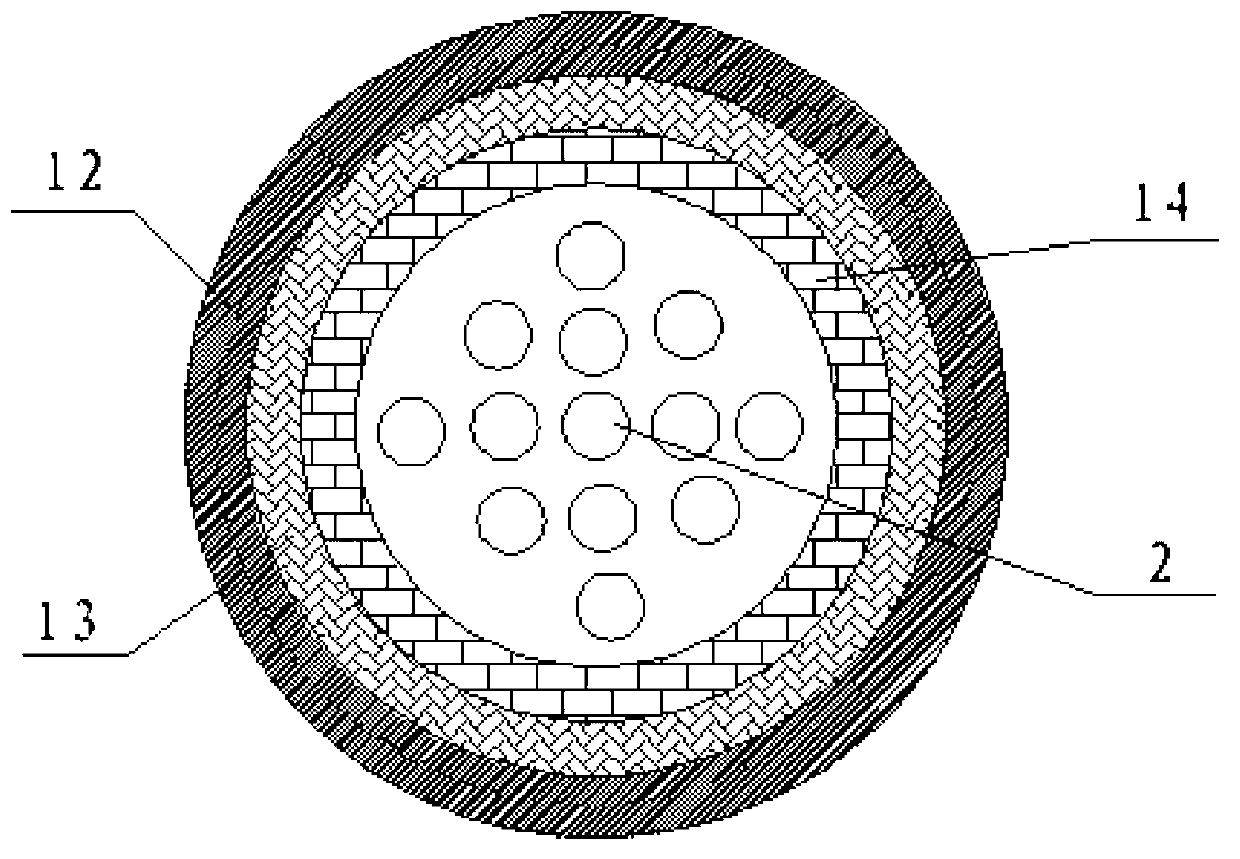

[0014] see figure 1 with figure 2 , a sintering device for ceramic tubes of sodium-sulfur batteries of the present invention, comprising a furnace 1 composed of a furnace bottom 11 and a furnace body 12, an insulating layer 13 and a lining 14 on the inner wall of the furnace 1, and a heating device (not shown in the figure), where:

[0015] The furnace bottom 11 has a disc structure, so that the ceramic tube body 2 is evenly distributed and buckled on the furnace bottom 11;

[0016] The inner cavity of the furnace body 12 is cylindrical and the top is arc-shaped, which is adapted to the shape of the furnace bottom 11, so that the furnace body 12 is bell-shaped as a whole, so that the temperature in the furnace is concentrated on the ceramic tube body 2, At the same time,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com