Hydrotalcite precursor adsorbent and preparation method thereof

A technology of hydrotalcite and precursor, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems that the adsorption capacity of calcium oxide is not as good as that of molecular sieves, and the adsorption rate is limited, so as to achieve low cost and increase Adsorption capacity and rate, high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Weigh 1.2800g Mg(NO 3 ) 2 ·6H 2 O and 0.6250g Al(NO 3 ) 3 9H 2 O was dissolved in 50 mL of deionized water to obtain a solution in which Mg 2+ with Al 3+ The molar ratio is 3:1, Mg 2+ The concentration is 0.1 mol / L;

[0029] 2. Add 2.840g (or excessive amount) of solid stearic acid into 100 mL deionized water at 70°C, and stir evenly;

[0030] 3. Mix the two solutions obtained in steps 1 and 2 evenly, add dropwise NaOH solution with a concentration of 0.1 mol / L to make the pH of the solution system = 9, transfer the above solution to an eggplant-shaped bottle, and quickly install the device after adding the magnet On the rotary evaporator, feed nitrogen protection;

[0031] 4. Set the reaction temperature to 80 °C, turn on the magnetic stirrer, and continue feeding nitrogen for 10 h;

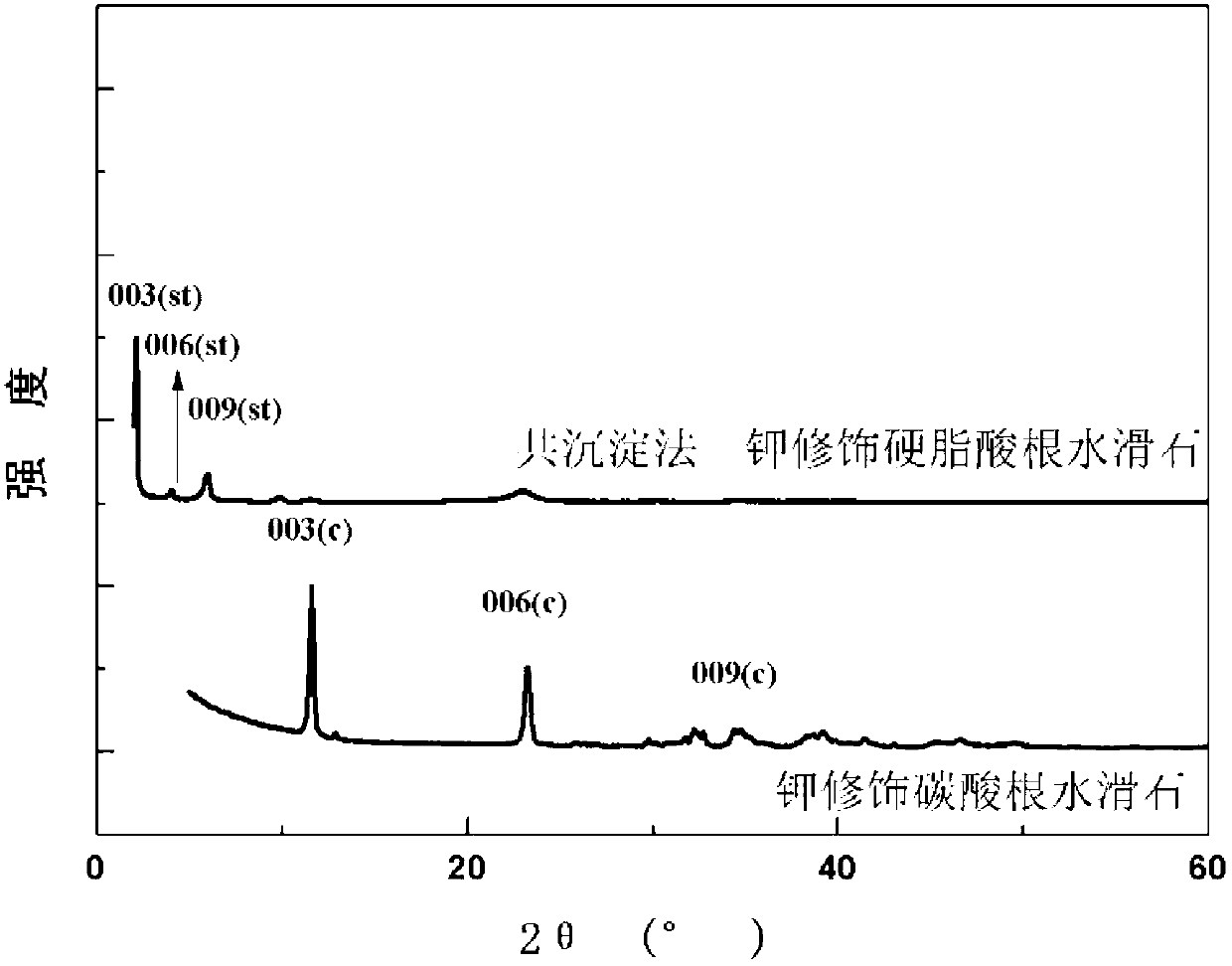

[0032] 5. Wash the reaction product with deionized water at 80 ℃ to make the pH = 7. After drying, grind it into powder with an agate mortar to obtain stearic acid and anion ...

Embodiment 2

[0039] 1. Weigh 3 g of purchased commercial hydrotalcite Sasol GmbH MG70 (cations are Mg and Al, anions are carbonates), and calcined at 450 °C for 18 h (under a protective gas atmosphere) to remove the original carbonate anions ;

[0040] 2. Dispose 1 g of calcined composite metal oxide and 2 g of stearic acid (excess) in a deionized aqueous solution, transfer the above solution to an eggplant-shaped bottle, add magnets and quickly install it in a rotary evaporator On, pass nitrogen protection;

[0041] 3. Set the reaction temperature to 80 °C, turn on the magnetic stirrer, and continue feeding nitrogen for 10 h;

[0042] 4. Wash the reaction product with deionized water at 80 ℃ to make the pH = 7. After drying, grind it into powder with an agate mortar to obtain stearic acid and anion-intercalated hydrotalcite, which can be filled with silica gel and soda lime in a drying dish waterproof and CO 2 save;

[0043] 5. Weigh 1 g of stearic acid and anion-intercalated hydrotal...

Embodiment 3

[0049] 1. Dissolve 1.325 g of commercial hydrotalcite Sasol GmbH MG70 and 1.53 g of sodium stearate in 150 mL of deionized water to obtain a solution;

[0050] 2. Add dilute hydrochloric acid with a concentration of 0.1 mol / L drop by drop until pH=4.0;

[0051] 3. Transfer the above solution to an eggplant-shaped bottle, quickly install it on a rotary evaporator after adding magnets, and pass it into nitrogen protection;

[0052] 4. Set the reaction temperature to 80 °C, turn on the magnetic stirrer, and continue feeding nitrogen for 10 h;

[0053] 5. Wash the reaction product with deionized water at 80 ℃ to make the pH = 7. After drying, grind it into powder with an agate mortar to obtain stearic acid and anion intercalated hydrotalcite, which can be filled with silica gel and soda lime in a drying dish waterproof and CO 2 save;

[0054] 6. Weigh 1 g of stearic acid and anion-intercalated hydrotalcite and 0.125 g of anhydrous potassium carbonate powder, place them in an eg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com