Photothermal conversion composition and preparation method thereof

A light-to-heat conversion and composition technology, which is applied in coating, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of low light-to-heat conversion efficiency, poor heat storage durability, and no application, and achieve light-to-heat conversion High efficiency, good heat storage and heat preservation, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

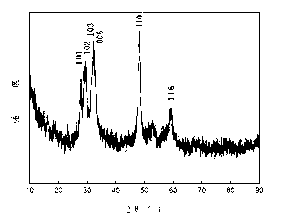

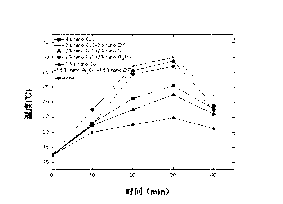

[0031] Take a 200ml small beaker, put into it in turn: 50g oily acrylic resin, 2g absorbent, 30g xylene, 2.5g HP-731 water-based dispersant, 0.5g HP-512 silicone defoamer, HP-868 silicone Ketone leveling agent 0.5g, PN-700 high-performance adhesion promoter 3g, after continuous mechanical stirring to disperse evenly, apply it to the inner wall surface of the plexiglass box of 8 cubic centimeters by spraying, and place it at room temperature 2 days to allow the coating to cure naturally. The photothermal effect test was carried out under the condition of an ambient temperature of 20°C, and the test results are shown in image 3 with table 1. The absorbing agent is the CuS semiconductor nanoparticle with super nanometer microstructure prepared by the above method.

Embodiment 2

[0033] Take a 200ml small beaker, put into it in turn: 50g oily acrylic resin, 2g absorbent, 30g xylene, 2.5g HP-731 water-based dispersant, 0.5g HP-512 silicone defoamer, HP-868 silicone Ketone leveling agent 0.5g, PN-700 high-performance adhesion promoter 3g, after continuous mechanical stirring to disperse evenly, apply it to the inner wall surface of the plexiglass box of 8 cubic centimeters by spraying, and place it at room temperature 2 days to allow the coating to cure naturally. The photothermal effect test was carried out under the condition of an ambient temperature of 20°C, and the test results are shown in image 3 with table 1.

[0034] The absorbent is a mixture of CuS semiconductor particles with a super nano-microstructure and nano-zirconium carbide, and it needs to be pretreated. The specific steps are: first put 1g of CuS semiconductor nanoparticles prepared by the above method into a 40°C oven Dry it within half an hour, then take it out and pour it into an ...

Embodiment 3

[0036] Take a 200ml small beaker, put into it in turn: 50g oily acrylic resin, 2g absorbent, 30g xylene, 2.5g HP-731 water-based dispersant, 0.5g HP-512 silicone defoamer, HP-868 silicone Ketone leveling agent 0.5g, PN-700 high-performance adhesion promoter 3g, after continuous mechanical stirring to disperse evenly, apply it to the inner wall surface of the plexiglass box of 8 cubic centimeters by spraying, and place it at room temperature 2 days to allow the coating to cure naturally. The photothermal effect test was carried out under the condition of an ambient temperature of 20°C, and the test results are shown in image 3 with table 1.

[0037] The absorbent is a mixture of CuS semiconductor particles with a super nano-microstructure and nano-silicon carbide, and needs to be pretreated. The specific steps are: first put 1g of the CuS semiconductor nanoparticles prepared by the above method into a 40°C oven Dry it within half an hour, then take it out and pour it into an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com